Whitworth Tube Thread Taps

Product Name: Pipe Thread Tap

Machining Materials: Copper/Aluminum/Die Steel/Alloy Steel/Cast Iron, etc.

Machining Process: Precision Grinding

Advantages: High-quality steel, integral forging; unique groove design facilitates chip removal; fast drilling speed; solid workmanship; neat, sharp, and durable cutting edge.

Features: Taps internal threads; high hardness; fast tapping speed; wear-resistant and heat-resistant.

Applications: Suitable for tapping machines, machining centers, milling machines, bench drills, CNC machine tools, etc. Pipe thread taps are widely used in industries such as manufacturing and furniture decoration, and are popular in various fields.

Uses: Mainly used for machining internal threads of water pipes, gas pipes, oil pipes, etc.

Note: Adding coolant during machining can improve the machining effect. Do not process roughly.

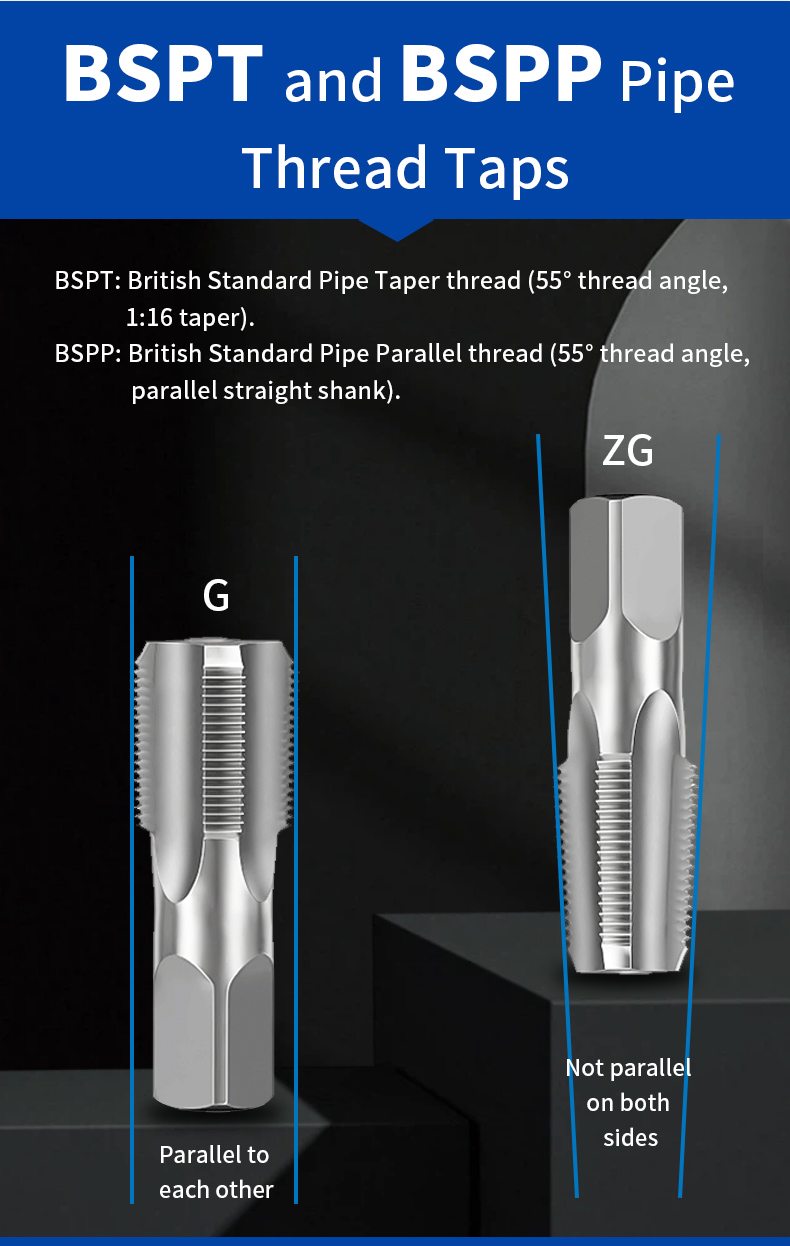

G: 55° British non-sealing cylindrical pipe thread

ZG: 55° British conical pipe thread

Z: 60° American conical pipe thread

NPT: 60° American sealing pipe thread

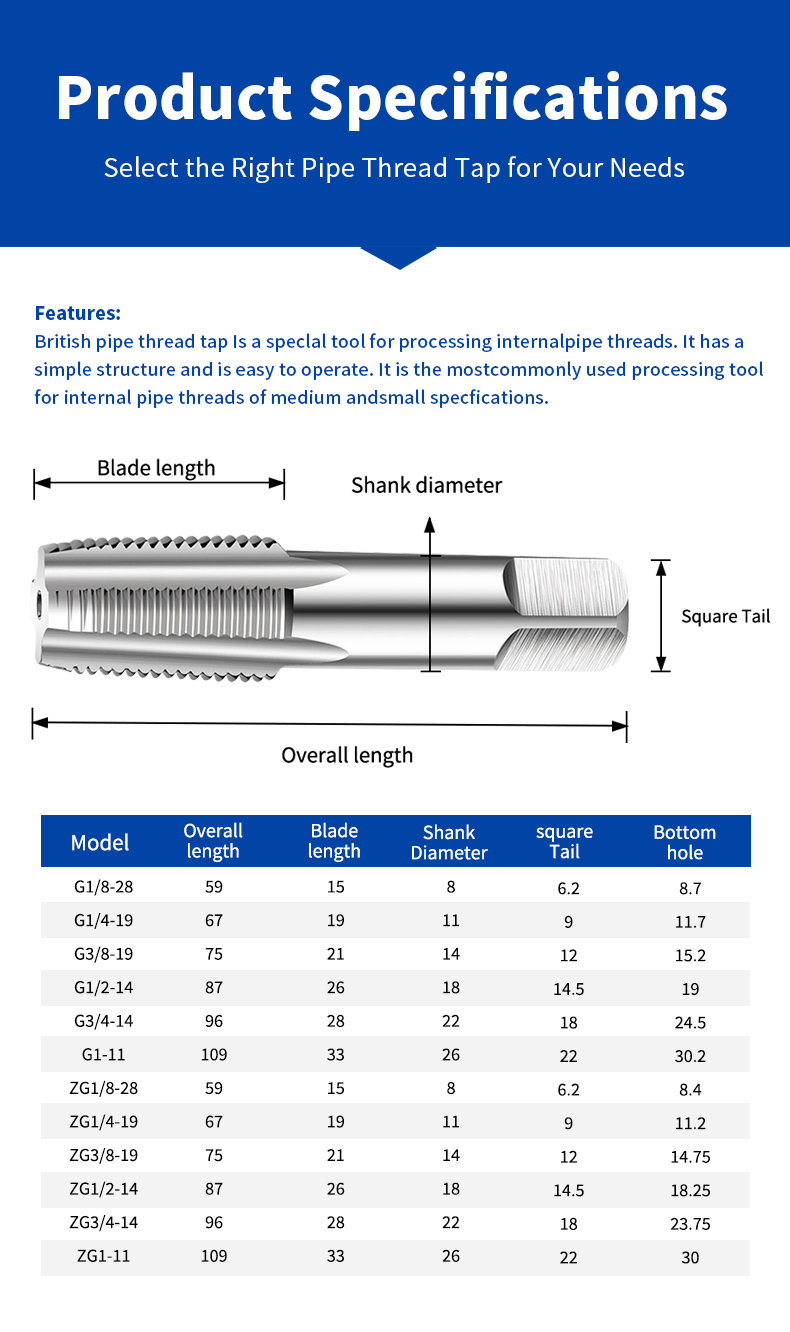

If drilling a pilot hole is required, select an appropriate drill bit (refer to the pipe thread taper parameter table).

Insert the tap vertically into the threaded hole. Try to maintain concentricity, then use a wrench to tighten it clockwise. Reverse the tap by 1/4 to 1/2 turn periodically to break and clear the chips.

Apply cutting lubricant to the cutting edge of the tap during threading.

This tap can be used both manually and by machine.

Please refer to the tap parameter table before purchasing to avoid unnecessary losses.

The above selection method is for reference only. If you have any doubts, please contact customer service for assistance in selecting the appropriate model.