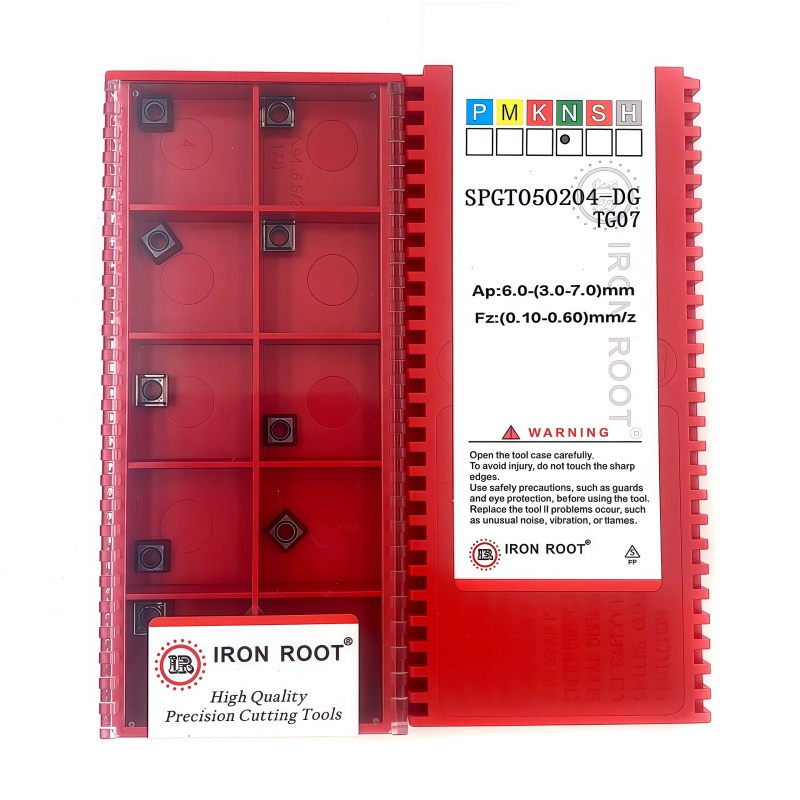

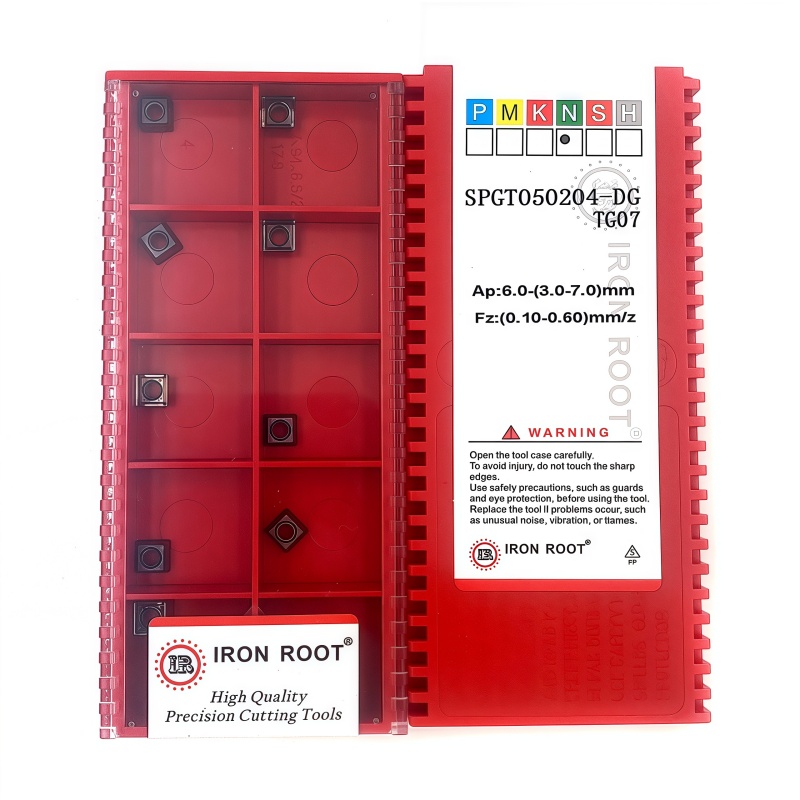

SPGT-DG TG07 Carbide Drill Bit for Precision Machining

1. Wide applicability

SPGT-DG drilling inserts are suitable for processing a variety of materials, including ordinary steel, quenched and tempered steel, stainless steel, cast iron, etc. Its design can meet workpieces of different hardness and processing requirements, and has good versatility.

2. Optimized geometry

The insert adopts a 90° positive angle design with an 11° end relief, which can effectively reduce cutting forces, improve cutting efficiency and processing accuracy. Its straight cutting edge and optimized drill tip structure further improve cutting performance.

3. High wear resistance and durability

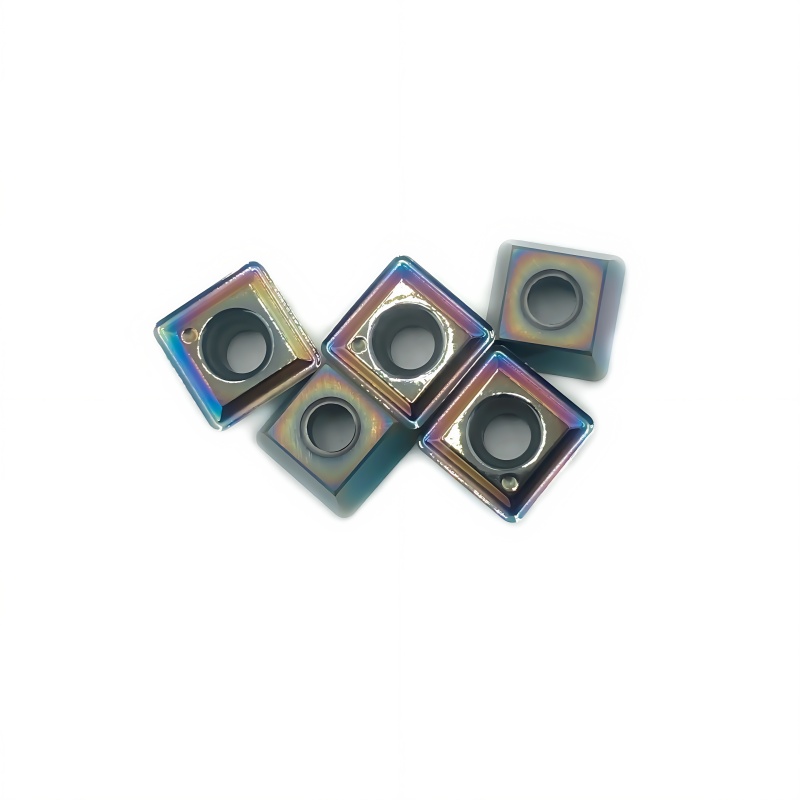

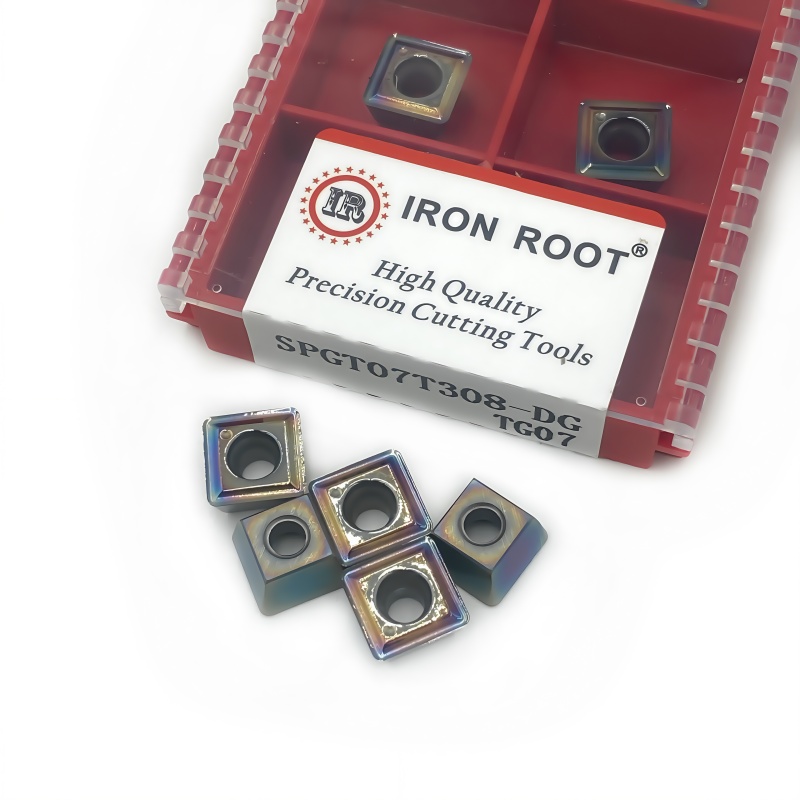

SPGT-DG inserts are usually made of carbide and combined with professional coating technology, such as PVD or CVD coating, which can significantly improve the wear resistance and service life of the insert. For example, TT8020 grade inserts are suitable for intermittent processing and rough processing of steel parts.

4. Efficient chip removal and cooling design

Some SPGT-DG inserts are designed with internal cooling liquid flushing function, which can effectively discharge chips, reduce chip accumulation and tool wear, while reducing processing temperature and improving processing efficiency.

5. Stable processing performance

The double-edge design and high-precision mounting structure of the blade can ensure a smooth cutting process with low vibration, thereby improving the accuracy and surface quality of hole processing.

The SPGT-DG series provides a variety of blade sizes and specifications to meet the processing needs of different diameters and cutting depths.

In the field of modern machining, the performance of drilling inserts directly affects machining efficiency, precision and cost. With the continuous advancement of industrial technology, the market demand for efficient, durable and economical drilling inserts is growing. Today, we introduce you to a drilling insert that is highly respected in the industry-SPGT-DG. It has become the first choice of many manufacturing companies for its excellent performance and wide range of applications. The SPGT-DG drilling insert adopts an advanced 90° positive angle geometric design, combined with an 11° end relief. This unique structure can significantly reduce cutting force and energy consumption during the cutting process, thereby greatly improving machining efficiency. Its linear cutting edge and optimized drill tip structure ensure the smoothness of the cutting process, while effectively reducing tool vibration, making the processed hole size more accurate and the surface quality better.

In addition, the SPGT-DG insert also has excellent chip removal performance. Its design allows chips to be discharged smoothly, avoiding tool wear and processing interruptions caused by chip accumulation, and further improving processing efficiency. This efficient cutting performance can maintain stable processing performance whether in continuous or intermittent processing.

In machining, the wear resistance and durability of the tool are one of the key indicators to measure its performance. SPGT-DG drilling inserts are made of high-quality carbide and combined with advanced PVD or CVD coating technology. This coating can not only significantly improve the wear resistance of the blade, but also effectively resist the erosion of high temperature and cutting fluid, and extend the service life of the tool.

Through the optimized coating process, SPGT-DG inserts perform well when processing high-hardness materials (such as stainless steel, cast iron, etc.), and can withstand greater cutting loads while maintaining stable cutting performance. This means that in actual machining, the frequency of blade replacement is greatly reduced, thereby reducing downtime and reducing machining costs. For machining, machining accuracy is the core standard for measuring product quality. SPGT-DG drilling inserts ensure the stability of the cutting process through double-edge design and high-precision mounting structure. This design can effectively reduce tool vibration, making the processed hole size more accurate and the surface roughness lower.

In addition, the indexable design of SPGT-DG inserts further improves machining flexibility. The multi-edge structure of the blade allows the cutting edge to be quickly replaced after wear without replacing the entire tool, which not only saves costs, but also reduces the processing errors caused by tool replacement, ensuring the continuity and stability of the processing process. SPGT-DG drilling inserts are suitable for the processing of a variety of materials, including ordinary steel, quenched and tempered steel, stainless steel, cast iron and aluminum alloy. Whether it is roughing or finishing, SPGT-DG can provide excellent performance. Its diverse specifications and size designs can meet the processing requirements of different diameters and cutting depths, and are suitable for processing from small parts to large machinery. While pursuing efficient processing, SPGT-DG drilling inserts also take into account economy and environmental protection. Its high durability and low replacement frequency significantly reduce the cost of tool use. At the same time, the optimized cutting performance reduces the use of cutting fluid and energy consumption, which is in line with the green processing concept of modern manufacturing.

| Type | Cutting Tool |

| Transport Package | Carton |

| Coating | Altin,Tisin |

| Origin | China |

| Certification | ISO 9001:2008, ISO 9001:2000, GS, CE |

| Production Capacity | 100000/Month |

SPGT-DG drilling inserts have become an ideal choice in the field of mechanical processing due to their efficient cutting performance, high wear resistance and durability, stable processing performance and wide range of applications. It can not only help users improve production efficiency and reduce processing costs, but also ensure the stability of processing quality. Whether you are engaged in automotive manufacturing, aerospace or general machining, SPGT-DG drilling inserts will be your reliable partner to enhance your competitiveness.