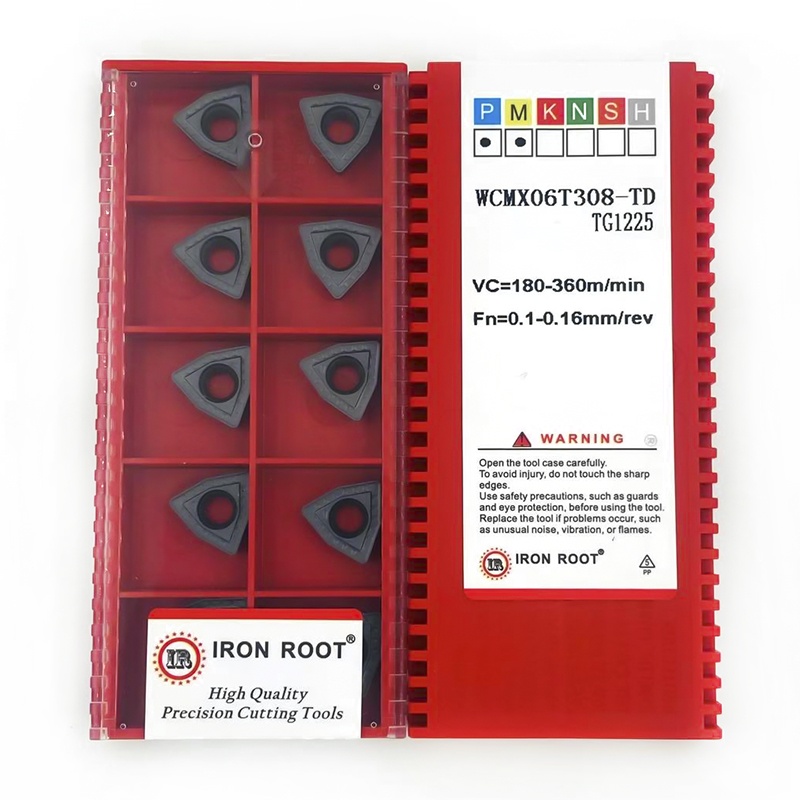

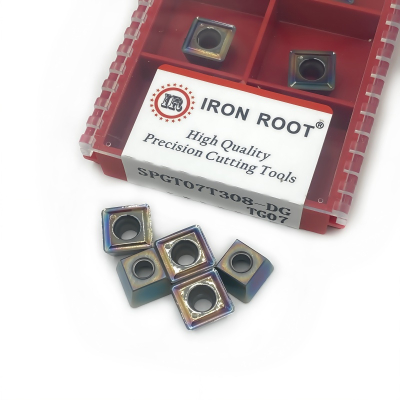

WCMX-TD TG1225 Carbide U Drill Insert High Precision

Cost-Effective Solution

Easy Installation and Replacement

Excellent Chip Evacuation

High-Speed Machining Capability

Environmentally Friendly Design

In the field of precision machining in modern manufacturing, choosing a tool with excellent performance is the key to improving machining efficiency and product quality. Today, we will introduce a highly anticipated U drill blade - WCMX-TD TG1225. This blade has become the first choice of many manufacturing companies due to its superior performance and wide range of applications.The WCMX-TD TG1225 U drill blade is made of high-quality cemented carbide material, which is world-renowned for its excellent hardness, wear resistance and impact resistance. Through advanced manufacturing processes and precision machining technology, each piece of WCMX-TD TG1225 has extremely high precision and consistency. The blade's geometry has been optimized to effectively reduce vibration and noise during cutting, ensuring a smooth and smooth machining process.

In order to further enhance the performance of the blade, WCMX-TD TG1225 uses advanced TiAlN coating technology. This coating not only improves the surface hardness of the blade, but also enhances its corrosion resistance and oxidation resistance. During the cutting process, the TiAlN coating can effectively reduce the friction between the blade and the workpiece, reduce the generation of heat, and thus extend the service life of the blade. Even under high-intensity machining conditions, the WCMX-TD TG1225 can maintain excellent cutting performance, providing reliable protection for your machining tasks. The WCMX-TD TG1225 U drill blade is designed to achieve efficient metal removal rates. Its unique geometry and sharp cutting edge can quickly cut materials while maintaining high-precision machining quality. This means that you can complete more machining tasks in a shorter time, significantly improving production efficiency. In addition, due to the durability and efficiency of the blade, the frequency of blade replacement is greatly reduced, thereby reducing tool consumption costs and equipment downtime, bringing tangible economic benefits to your business.

The WCMX-TD TG1225 U drill blade is suitable for a variety of machining scenarios and materials. Whether it is steel, stainless steel, cast iron or non-ferrous metal, this blade can easily cope with it. It is widely used in automotive manufacturing, machining, aerospace and other fields. Whether it is large-scale mass production or small-scale precision machining tasks, the WCMX-TD TG1225 can perform well and meet the diverse needs of different industries and enterprises. The design of the WCMX-TD TG1225 U drill blade fully considers the convenience of users. It can be quickly installed in a compatible U drill chuck, and the standardized size and stable clamping mechanism ensure the stability and safety of the blade during high-speed cutting. This convenient installation method greatly reduces the time for equipment adjustment and blade replacement, making your production process more efficient and smooth.

Choosing WCMX-TD TG1225 U drill blade means choosing precision, efficiency and reliability. It will bring a new experience to your processing tasks, help your company stand out in the fierce market competition, and achieve higher production efficiency and more excellent product quality.