M6*0.75-6H precision measuring instrument

High-precision measurement

High accuracy: The M6*0.75-6H gauge adopts a high-precision manufacturing process, which can accurately measure the size and shape of the internal thread and ensure the accuracy of the measurement results.

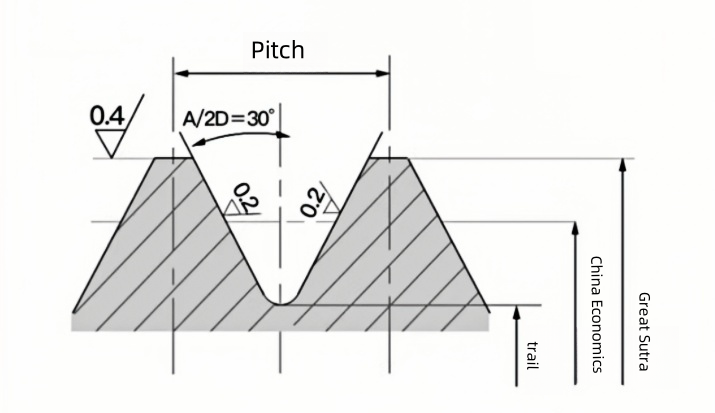

Compliance with standards: Following the international standard ANSI/ASME B1.16M, the reliability and consistency of the gauge are guaranteed.

High-quality materials and durability

High-quality materials: Usually made of high-quality materials such as high-speed steel (HSS), it has good hardness and wear resistance, and extends the service life.

Hardening treatment: After hardening treatment, the hardness can reach 64HrC, ensuring that high accuracy can be maintained under frequent use.

About the product

This M6*0.75-6H gauge is a high-precision tool designed for accurate measurement of internal threads. It is made of high-quality materials to ensure the durability of the product and the accuracy of measurement. The design of the gauge meets international standards and is suitable for a variety of industrial application scenarios, such as machining, automotive parts manufacturing, etc. It is easy to operate and easy to read the measurement results, which can effectively improve work efficiency. At the same time, the product also provides a professional calibration certificate to ensure the reliability of the measurement results.

Material & Construction

Product Advantages

High-precision measurement: Following the international standard ANSI/ASME B1.16M, it can accurately measure the size and shape of internal threads to ensure the accuracy of the measurement results.

High-quality materials and durability: Usually made of high-quality materials such as high-speed steel (HSS), it has good hardness and wear resistance and extends the service life.

Perfect calibration and certification: Provide professional calibration certificates to ensure that the measurement accuracy of the measuring tool meets industry standards. Some products also provide authoritative certifications such as UKAS to meet the certification needs of different customers.

Diversified design and applicability: There are various types such as plug gauges and ring gauges to choose from to meet different measurement needs. Suitable for thread detection in various industries, such as machinery manufacturing, automotive parts production, etc.

Easy to use and maintain: Reasonable design, easy to operate and read measurement results, and improve work efficiency. Simple structure, easy to clean and maintain, ensure long-term and stable use of measuring tools.

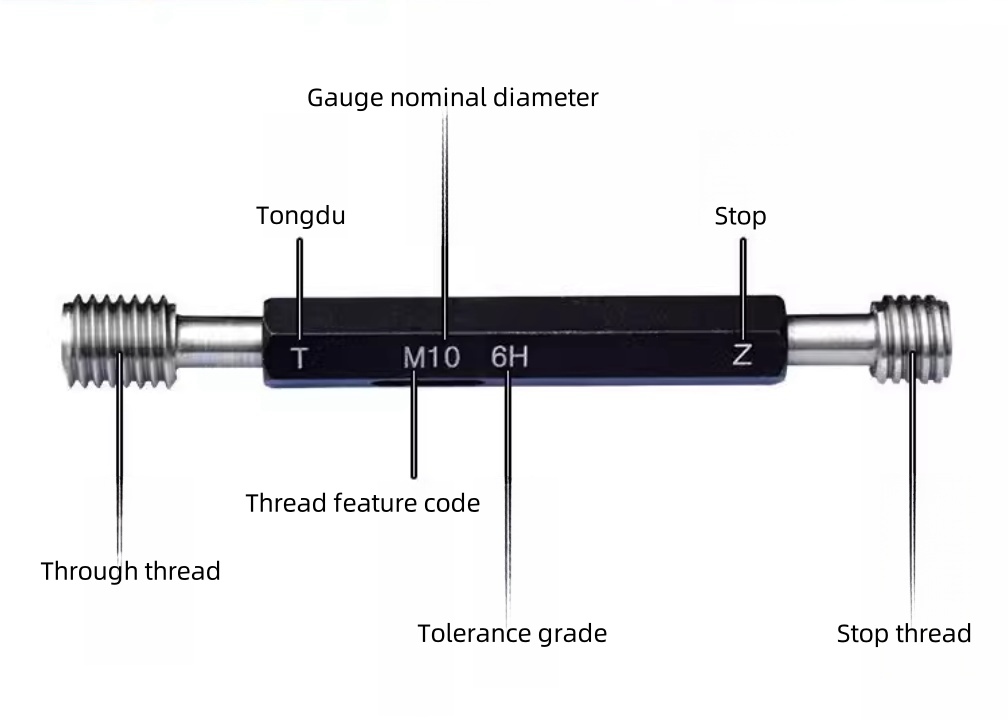

Product: | 6H Metric Thread Plug Gauge |

| Tolerance Grade: | 6H |

| Surface Treatment: | Heat Treatment |

| Packaging: | Molded Plastic Box |

| Material: | Bearing Steel |

| Type: | Thread Gauge |

Correct operation method of M6*0.75-6H gauge:

Preparation before operation

Inspect the gauge: Before use, check whether the gauge is intact and ensure that there are no defects such as rust, wear or scratches on its surface.

Calibrate the gauge: Before use, the zero position of the gauge should be calibrated, the error value should be determined and the correction amount should be remembered so that correction can be made when reading.

Clean the gauge and workpiece: Clean the oil, impurities, burrs, etc. on the surface of the gauge and the measured workpiece to ensure the accuracy of the measurement.

Operation steps

Choose a suitable gauge: According to the specifications of the measured thread, select a matching M6*0.75-6H gauge.

Align the thread: Align the through end (GO) or stop end (NO-GO) of the gauge with the measured thread to ensure that the two are coaxial.

Rotate the gauge: Use your thumb and index finger to gently turn the gauge or the measured part to rotate in a free state. Normally, the through end should be screwed in smoothly at any position of the measured thread and pass through the entire thread length; the stop end is qualified if it is screwed into the thread length within 2 pitches.

Reading results: Determine whether the thread is qualified based on the matching of the measuring tool and the measured thread. If the through end can pass smoothly and the stop end stops within the specified pitch, the measured thread is qualified.

Withdrawing the measuring tool: When withdrawing the measuring tool, it should rotate naturally and smoothly to avoid excessive force or skewness.

Precautions

Operation force: During the measurement process, avoid excessive or too light force to avoid inaccurate measurement results.

Keep the measuring tool dry: The measuring tool should be kept dry and avoid using or storing it in a humid environment to avoid affecting the measurement accuracy.

Regular maintenance: Clean the stains on the measuring tool in time after use, and store it properly in a dry and ventilated place to avoid mixing with other tools.

Environmental conditions: Try to use and store the measuring tool at room temperature (15-25℃), and avoid placing it in high or low temperature environment for a long time to avoid affecting the measurement accuracy.

Applications

About Our Company

Jinan Xinxin Trading Co., Ltd. is a company specializing in a full range of turning tools, milling tools, holemaking tools, carbide cutting tools, machine tool accessories and

other products. At the same time, we accept non-standard product customization and provide perfect tooling solutions for the machining and manufacturing industry.

After years of development, our company firmly believe in the concept of integrity-based, with high-quality service so that the company's products are exported to

Europe, the Middle East, South America, Southeast Asia throughout the world's more than 40 industrialized countries and regions, won the majority of domestic

and foreign customers to support and trust.

Jinan Xinxin Trading Co., Ltd. was founded in 2012, is an excellent comprehensive imported CNC cutting tools agents in Shandong, the company firmly believe in

the concept of good faith, with high quality and attentive service. The company believes in the concept of good faith, with high quality and attentive service. For

the various machining enterprises to supply the world's famous brands of imported CNC cutting tools, machining center tools.

Company Brands

Our company brand IRONROOT series products, with excellent quality and perfect service, strive to reduce the cost of using tools for you.

Main products

Our company, as an important link in the machining field, is following and driving its whole system to run. Our distribution of products has become increasingly systematized, mainly including: Sandvik Coromant sandvikcoromant, Seco, Walter, Kennametal Group Kennametal, Mitsubishi MITSUBISHI, Sumitomo Sumitomo, Kyocera Sholette Kyocera CERATIP, Toshiba, Daijie, Hitachi Tools HITACHI TOOL, ISCAR ISCAR, German cobalt collar Guehring, TEGUTEC TAEGUTEC, KORLOY KORLOY and so on.

Domestic brands: Zhuzhou Diamond Brand, Zigong Great Wall Brand, Zhuzhou Jingcheng Brand, Chengdu Yingge, Ha Yigong, Harbin Tool Factory, Southwest Tools, Chengqi Tools, Shaanxi Cemented Carbide, Zhuzhou Cemented Carbide, Guizhou Yihai, Shanghai Tool Factory and a series of domestic and foreign well-known brands of manufacturers of various types and specifications of CNC blades, Metal lathe tools CNC cutting tools, whole tools, machine-clamped blades, welded blades, toolposts, shank, holder, tungsten steel slats, bars. Tungsten steel slats and bars.

At present, our company's product range includes turning tools, milling tools, drilling tools, tooling systems, carbide cutting tools, machine tool accessories and so on.

Our Customer Reviews

Our products are exported to various countries, including the United States, the United Kingdom, Spain, Italy, Belgium, France, Germany, etc., and are deeply loved and supported by users in these countries. Our products are cost-effective, quality guaranteed, and genuine products.

Thank you very much for watching

Welcome to inquire about the prices, and we will provide you with the best service.

Website: https://www.ironrootcnctools.

Whatsapp/Mobile: +86 13969129141

Email: lronroot190@gmail.com