WCMX TG4105 U Drill Insert for Metal Cutting

Precision Engineering

Superior Wear Resistance

Advanced Coating Technology

High Metal Removal Rate

Versatile Application Range

Cost-Effective Solution

Easy Installation and Replacement

Excellent Chip Evacuation

High-Speed Machining Capability

Environmentally Friendly Design

The WCMX TG4105 U drill insert is a high-precision cutting tool designed for optimal performance in various machining applications. Crafted from high-quality tungsten carbide material, this insert offers excellent wear resistance and durability. The advanced TiAlN coating technology enhances its surface hardness and corrosion resistance, ensuring longer tool life even under demanding cutting conditions.

Key Features

High Precision: Manufactured to exacting standards for accuracy and consistency.

Durable Material: Made from high-quality carbide for superior wear resistance.

ompatible: Designed for use in CNC machining centers and conventional drilling equipment.

Application Range

This U drill insert is ideal for processing various materials including steel, stainless steel, cast iron, and non-ferrous metals. It is particularly suited for environments where high precision and efficiency are required, such as automotive manufacturing, mechanical processing, and aerospace industries.

Usage Method

The WCMX TG4105 U drill insert is designed for easy installation and replacement. It can be quickly mounted onto compatible U drill holders, ensuring minimal downtime during tool changes. The standardized dimensions and secure clamping mechanism guarantee stable performance during high-speed cutting processes.

Product Advantages

High Metal Removal Rate: Achieves efficient material removal while maintaining precision.

Cost-Effective: Reduces replacement frequency and operational costs.

Wide Material Compatibility: Versatile for various metals and alloys.

Easy Handling: Quick installation and replacement minimize downtime.

Superior Performance: Maintains stability and accuracy in high-speed machining.

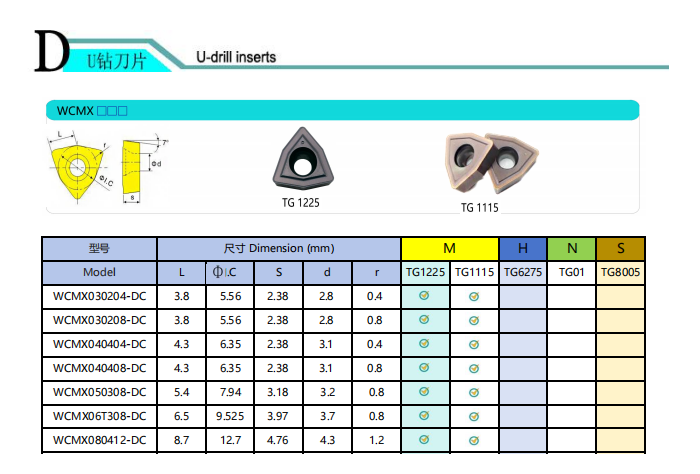

| Model | Dimension (mm) | ||||

| L | C | S | d | r | |

WCMX030204-DC | 3.8 | 5.56 | 2.38 | 2.8 | 0.4 |

| WCMX030208-DC | 3.8 | 5.56 | 2.38 | 2.8 | 0.8 |

| WCMXO40404-DC | 4.3 | 6.35 | 2.38 | 3.1 | 0.4 |

| WCMX040408-DC | 4.3 | 6.35 | 2.38 | 3.1 | 0.8 |

| WCMX050308-DC | 5.4 | 7.94 | 3.18 | 3.2 | 0.8 |

| WCMX06T308-DC | 6.5 | 9.525 | 3.97 | 3.7 | 0.8 |

| WCMX080412-DC | 8.7 | 12.7 | 4.76 | 4.3 | 1.2 |

Technical Specifications

Material: Tungsten carbide

Dimensions: WCMX TG4105

Application: CNC machining centers, drilling equipment

Maintenance Recommendations

Regularly clean the insert to remove metal chips and debris.

Inspect for signs of wear or damage after each use.

Store in a dry, clean environment to prevent corrosion.

Follow manufacturer guidelines for optimal performance.

By incorporating this U drill insert into your machining operations, you can expect enhanced efficiency, reduced operational costs, and consistent professional results across diverse applications.