ironroot SPB Series: A Game-Changer for CNC Slotting

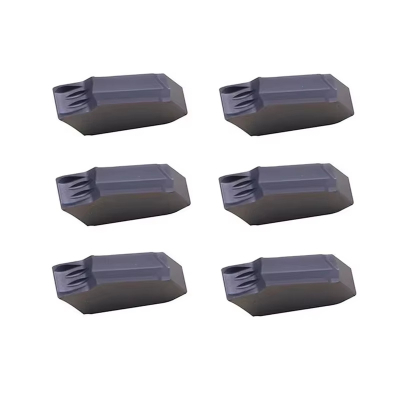

The recent launch of the IRON ROOT SPB Series CNC lathe slotting blades, paired with SP carbide inserts, has sparked widespread attention in the manufacturing industry. Designed to handle diverse slotting tasks with models ranging from 226 and 232 to 26-5 and 32-6, this product line is redefining precision and efficiency in metalworking—with user feedback highlighting its transformative impact on daily operations.

Another user, Elena Rodriguez, a CNC operator at MetalWorks Inc., emphasizes the versatility of the IRON ROOT SPB Series. “We handle a mix of steel and cast iron parts, each requiring different slot sizes. The range of sizes in the IRON ROOT SPB lineup—like the 26-5 for shallow grooves and 32-6 for deeper cuts—means we rarely need to switch tool holders. The SP carbide inserts hold their edge even during long runs, which is a game-changer for meeting tight deadlines.”

Industry experts note that the IRON ROOT SPB Series addresses two critical pain points in manufacturing: tool longevity and process stability. By combining durable materials with precision engineering, the blades minimize downtime and ensure consistent results, factors that directly contribute to cost savings for businesses.

With positive user experiences mounting, the IRON ROOT SPB Series is poised to become a staple in CNC lathe operations, setting a new standard for slotting performance in the industry.