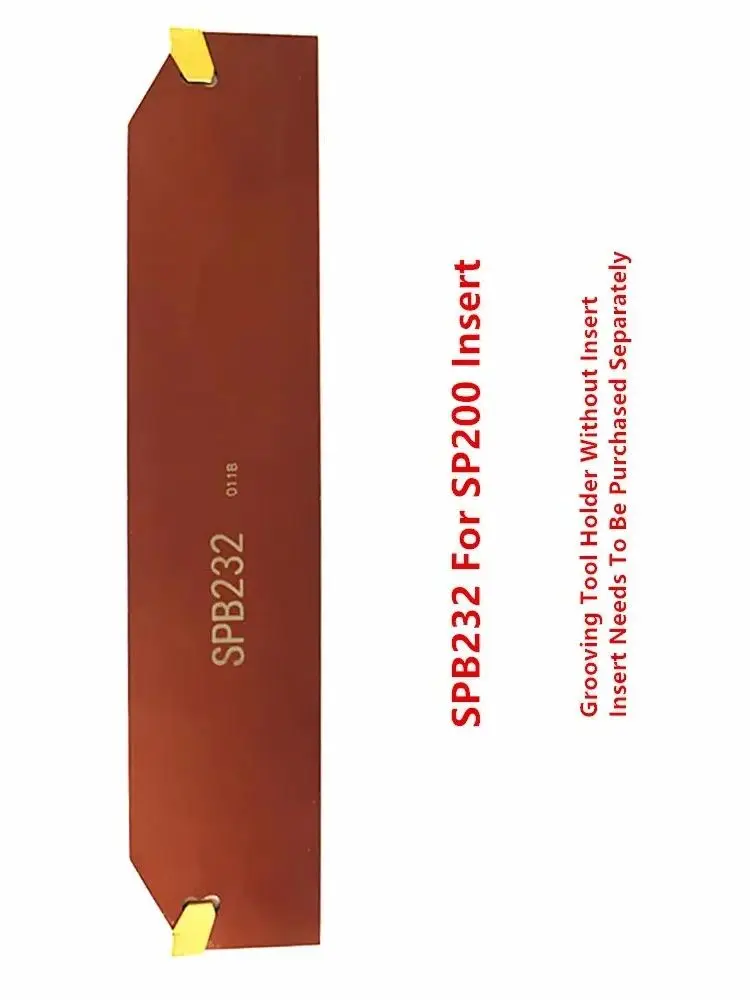

ironroot SPB Series CNC Lathe Slotting Blades with SP Carbide Inserts

Material

Crafted from premium SP-grade carbide, SPB Series these inserts boast a high cobalt content (5-8%) for enhanced toughness,

paired with ultra-fine grain structure (0.8-1.2μm) that delivers exceptional hardness (up to 92 HRA). This unique composition

balances wear resistance and impact strength, outperforming standard carbide in high-stress machining.

Key Features

Extended Lifespan: Designed to last 3-5 times longer than high-speed steel (HSS) inserts. In continuous CNC operations

(8-hour shifts), they maintain sharpness for 200+ workpieces on average, reducing tool change frequency.

Enhanced Stability: SPB CNC Lathe Slotting Blades Precise clamping grooves (tolerance ±0.01mm) ensure a rock-solid

fit in tool holders,

minimizing vibration—critical for achieving Ra 0.8μm surface finishes on slots.

Heat & Wear Resistance: Withstands cutting temperatures up to 1,200°C, making it ideal for dry machining or minimal

coolant setups without compromising performance.

Applications

Perfect for slotting tasks across industries:

Automotive: Machining keyways in crankshafts, piston grooves, and transmission components.

Machinery Manufacturing:SP Carbide Inserts Cutting annular slots in bearing housings, rectangular grooves in gears, and stepped slots in hydraulic valves.

Aerospace: Processing precision slots in stainless steel or titanium alloy parts (e.g., engine brackets).

Compatible Machines

Optimized for CNC lathes, including:

Horizontal CNC lathes (e.g., Haas ST-20, Mazak Quick Turn)

Vertical CNC lathes (e.g., Okuma VTM series)

Automated lathes with slotting attachments, supporting both single-point and multi-axis slotting operations.

Geometry Advantages

SP Carbide Inserts The unique blade profile features a 10° rake angle and curved chip breaker, facilitating smooth

chip evacuation—even when machining ductile materials like low-carbon steel. This prevents chip jamming,

reducing workpiece scuffing and tool damage.

The ironroot SPB Series CNC lathe slotting blades are reliable tools designed for performing slotting operations of varying complexity. With a wide range of sizes (including 226, 232, 26-5, 32-6, and more), they easily adapt to the specifics of each task, whether it’s a small precision slot or a deeper groove.

A key advantage lies in the use of SP carbide inserts: their unique composition provides high hardness and wear resistance, which is particularly crucial when machining hard materials. Even during prolonged use, the blades maintain a sharp edge, reducing replacement frequency and minimizing equipment downtime.

The optimized geometry of the working part improves chip removal, preventing clogging and damaging the workpiece surface. This ensures excellent machining quality that meets high industrial production standards.

Thanks to their versatility, the ironroot SPB Series is suitable for working with steel, stainless steel, cast iron, and other materials, making them essential across various industries — from machinery manufacturing to automotive production. Precise clamping in tool holders ensures cutting stability, minimizing vibrations and delivering high dimensional accuracy, which is especially important for critical components.

The ironroot SPB Series combines durability, efficiency, and versatility, designed to enhance the productivity of lathe slotting operations.