SPGT-DG TG07 Is An Excellent Choice For Efficient Drilling

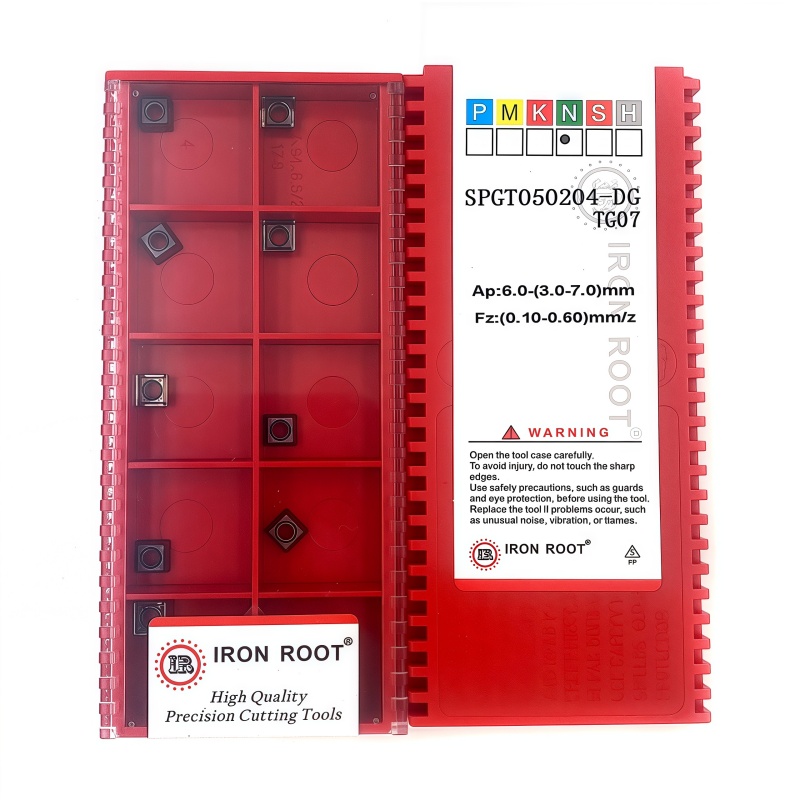

In the field of mechanical processing, the choice of cutting tools plays a vital role in processing efficiency and quality. Today, we are going to introduce the SPGT-DG TG07 drilling blade, a high-performance blade. With its excellent performance and wide range of applications, it has become the first choice of many processing companies.The SPGT-DG TG07 drilling blade is made of carbide, which has high strength and wear resistance and can withstand high-load processing tasks. The surface is treated with a special coating to further enhance the wear and corrosion resistance, greatly extending the service life of the blade. In terms of size, the blade has a diameter of 7.94 mm, a thickness of 3.97 mm, a cutting edge radius of 0.8 mm, and a tip arc radius of 2.85 mm. These precise dimensional designs enable it to adapt to a variety of drilling scenarios, whether it is ordinary steel, quenched and tempered steel, stainless steel or titanium alloy, it can easily cope with and meet the processing needs of materials with different hardness and strength.

As a well-known tool manufacturer in South Korea, Taguchi has more than 40 years of tool manufacturing experience, and its investment in technology research and development has never stopped. Advanced production equipment and testing technology ensure the high quality of each tool. The SPGT-DG TG07 drilling insert can achieve higher feed speed and cutting speed during the processing process with its optimized geometry and coating technology. Compared with traditional inserts, the processing efficiency can be increased by more than 20%, which is undoubtedly a huge advantage for processing companies pursuing efficient production.

In practical applications, SPGT-DG TG07 drilling inserts are widely used in mechanical processing, automobile manufacturing, aerospace and other fields. Whether it is the processing of parts of large machinery, the manufacturing of key parts of automobile engines, or the demand for high-precision parts in the aerospace field, this insert can provide strong support for the production of enterprises with its stable performance and excellent processing effect. Its stability during the processing process can effectively reduce tool wear and replacement frequency, thereby reducing production costs and improving the economic benefits of enterprises.

In short, the SPGT-DG TG07 drilling insert has become a sharp tool in the field of mechanical processing with its excellent performance and wide range of applications. Choosing it means choosing an efficient, stable and reliable processing experience. If your business is looking for a drilling insert that can improve processing efficiency and quality, then SPGT-DG TG07 is definitely worth your consideration.