ASRF12 CNC Milling Machine Tool Holder

1. ASRF12 milling tool holder for efficient roughing.

4. Milling machine tool holder for shock resistance and durability.

6. CNC milling tool holder for long service life.

7. Professional chip breaker design.

About the product

Description:

1.ASRF12 milling tool holder is suitable for efficient roughing and can provide fast metal removal rate.

2. The milling machine tool holder can be adapted to SDMT type milling inserts, which increases the flexibility of use.

3. The ASRF12 milling tool holder is shock-resistant and durable, which makes it more stable and durable when subjected to high-load processing.

4. The CNC milling tool holder has professional chipbreakers, which helps to provide perfect cutting performance and reduce chip problems during processing.

The ASRF12 milling tool holder is constructed from high-grade alloy steel (e.g., 42CrMo), selected for its exceptional strength and toughness. It undergoes precision heat treatment, achieving a hardness of HRC 50-55, which enhances its shock resistance and durability under high-load machining conditions. The surface is treated with anti-corrosion plating to resist wear and rust, ensuring long-term structural integrity in industrial environments.

High-Efficiency Roughing: Optimized for fast metal removal rates, making it ideal for roughing operations where large volumes of material need to be removed quickly, reducing overall machining cycle times.

SDMT Insert Compatibility: Designed to seamlessly adapt to SDMT type milling inserts, offering versatile tooling options to match different workpiece materials (e.g., steel, cast iron) and machining requirements, boosting operational flexibility.

Shock-Resistant Design: Engineered with enhanced structural rigidity to withstand high-load processing. This shock resistance minimizes vibration during cutting, ensuring stable performance and reducing premature wear on both the holder and inserts.

Professional Chip Management: Integrates dedicated chipbreakers that control chip flow and evacuation. This prevents chip clogging, reduces friction, and maintains consistent cutting performance, even in heavy-duty roughing tasks.

- Applications

- Primarily designed for efficient roughing operations across industries:

Automotive Manufacturing: Removing excess material from engine blocks, gear blanks, and chassis components.

Heavy Machinery: Roughing large cast iron or steel workpieces (e.g., machine bases, hydraulic cylinder housings).

General Engineering: Batch processing of structural parts requiring fast material removal before finishing.

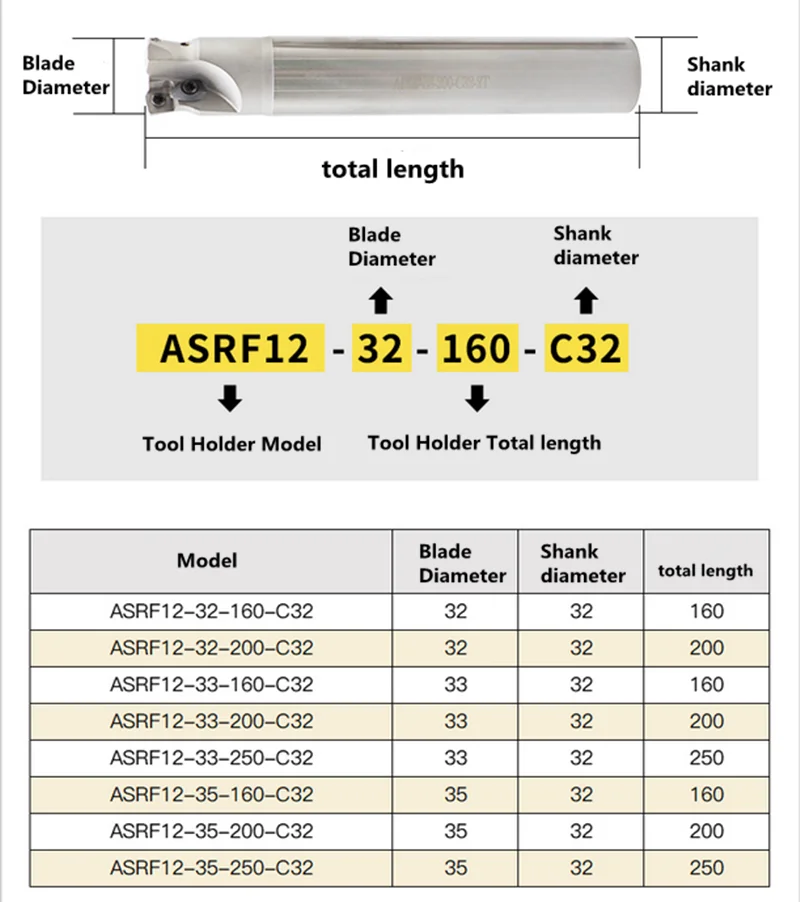

ASRF12 CNC Milling Machine Tool Hlder Models | |

ASRF12-32-2T-C32-150 | ASRF12-33-2T-C32-250 |

ASRF12-32-2T-C32-160 | ASRF12-35-2T-C32-150 |

ASRF12-32-2T-C32-200 | ASRF12-35-2T-C32-160 |

ASRF12-32-2T-C32-250 | ASRF12-35-2T-C32-200 |

ASRF12-33-2T-C32-150 | ASRF12-35-2T-C32-250 |

CNC vertical machining centers (VMCs) equipped with standard tool change systems.

CNC horizontal machining centers (HMCs) for heavy-duty roughing applications.

High-power milling machines with sufficient spindle torque to support high-load cutting.

Tool Holder: With proper maintenance (regular cleaning, lubrication of clamping components), the ASRF12 holder maintains stability and durability for 8,000+ hours of operation under typical roughing conditions.

Inserts: When paired with SDMT inserts, the holder’s shock-resistant design and chip management features extend insert lifespan by 20-25% compared to standard holders, thanks to reduced vibration and even wear distribution.

The rigid construction ensures minimal runout (≤0.01mm), contributing to consistent cutting accuracy during roughing.

Easy insert replacement design reduces tool change downtime, supporting continuous production workflows.

Ordering Information:

For accurate pricing and delivery details for our ASRF12 CNC Milling Machine Tool Holder, please reach out to our sales team. We also provide tailored solutions to fit your unique project needs. Let us help you find the perfect match for your requirements.

About Our Company

Jinan Xinxin Trading Co., Ltd. is a company specializing in a full range of turning tools, milling tools, holemaking tools, carbide cutting tools, machine tool accessories and

other products. At the same time, we accept non-standard product customization and provide perfect tooling solutions for the machining and manufacturing industry.

After years of development, our company firmly believe in the concept of integrity-based, with high-quality service so that the company's products are exported to

Europe, the Middle East, South America, Southeast Asia throughout the world's more than 40 industrialized countries and regions, won the majority of domestic

and foreign customers to support and trust.

Jinan Xinxin Trading Co., Ltd. was founded in 2012, is an excellent comprehensive imported CNC cutting tools agents in Shandong, the company firmly believe in

the concept of good faith, with high quality and attentive service. The company believes in the concept of good faith, with high quality and attentive service. For

the various machining enterprises to supply the world's famous brands of imported CNC cutting tools, machining center tools.

Company Brands

Our company brand IRONROOT series products, with excellent quality and perfect service, strive to reduce the cost of using tools for you.

Main products

Our company, as an important link in the machining field, is following and driving its whole system to run. Our distribution of products has become increasingly systematized, mainly including: Sandvik Coromant sandvikcoromant, Seco, Walter, Kennametal Group Kennametal, Mitsubishi MITSUBISHI, Sumitomo Sumitomo, Kyocera Sholette Kyocera CERATIP, Toshiba, Daijie, Hitachi Tools HITACHI TOOL, ISCAR ISCAR, German cobalt collar Guehring, TEGUTEC TAEGUTEC, KORLOY KORLOY and so on.

Domestic brands: Zhuzhou Diamond Brand, Zigong Great Wall Brand, Zhuzhou Jingcheng Brand, Chengdu Yingge, Ha Yigong, Harbin Tool Factory, Southwest Tools, Chengqi Tools, Shaanxi Cemented Carbide, Zhuzhou Cemented Carbide, Guizhou Yihai, Shanghai Tool Factory and a series of domestic and foreign well-known brands of manufacturers of various types and specifications of CNC blades, Metal lathe tools CNC cutting tools, whole tools, machine-clamped blades, welded blades, toolposts, shank, holder, tungsten steel slats, bars. Tungsten steel slats and bars.

At present, our company's product range includes turning tools, milling tools, drilling tools, tooling systems, carbide cutting tools, machine tool accessories and so on.

Our Customer Reviews

Our products are exported to various countries,milling insert including the United States, the United Kingdom, Spain, Italy, Belgium, France, Germany, etc., and are deeply loved and supported by users in these countries. Metal lathe tools

Thank you very much for watching

Welcome to inquire about the prices, and we will provide you with the best service.

Website: https://www.ironrootcnctools.

Whatsapp/Mobile: +86 13969129141

Email: lronroot190@gmail.com