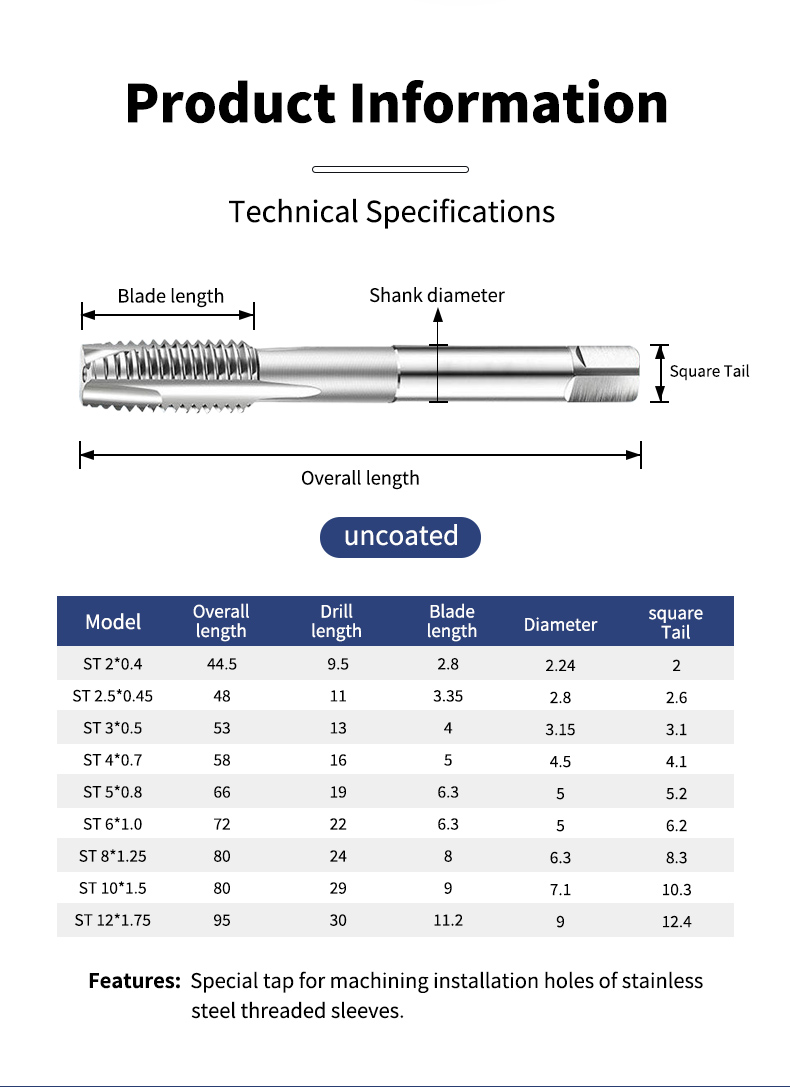

ST Thread Insert Tap Steel Wire Insert Threaded Sleeve

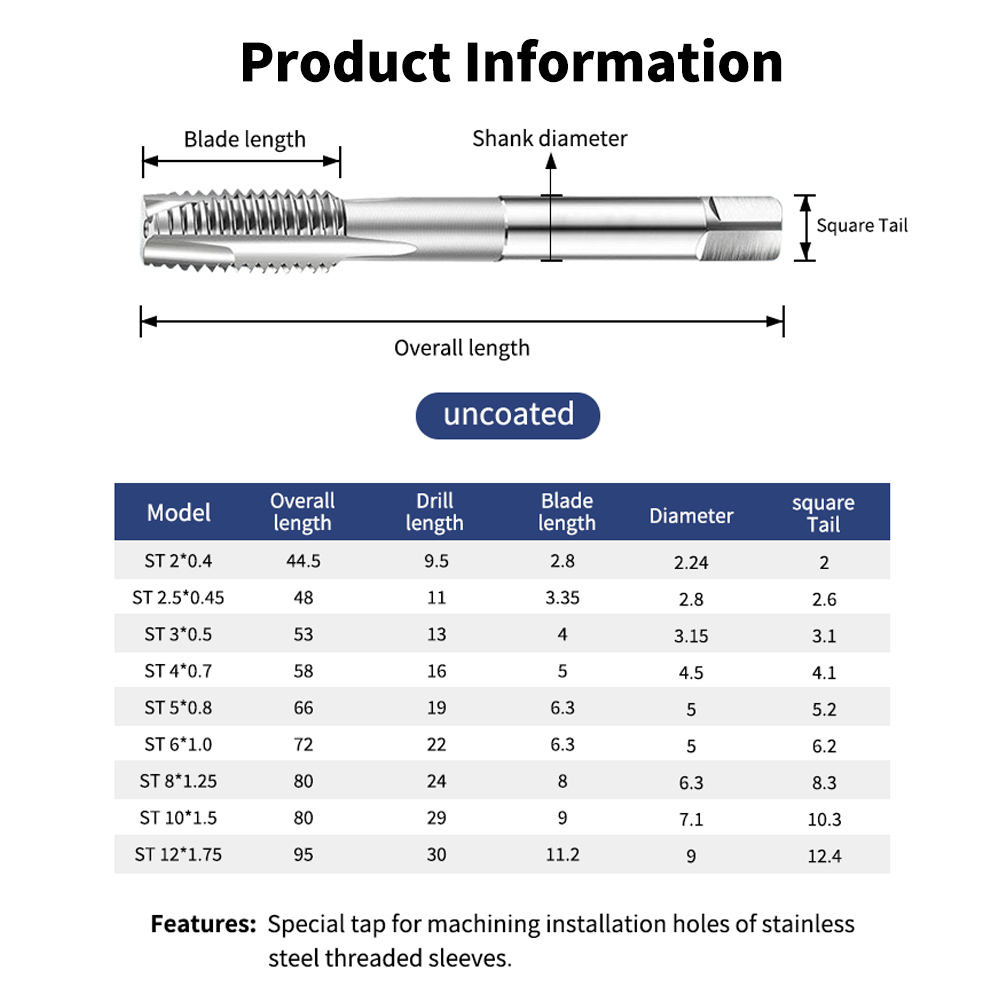

Basic Parameters

Product Name: Thread Insert Tap

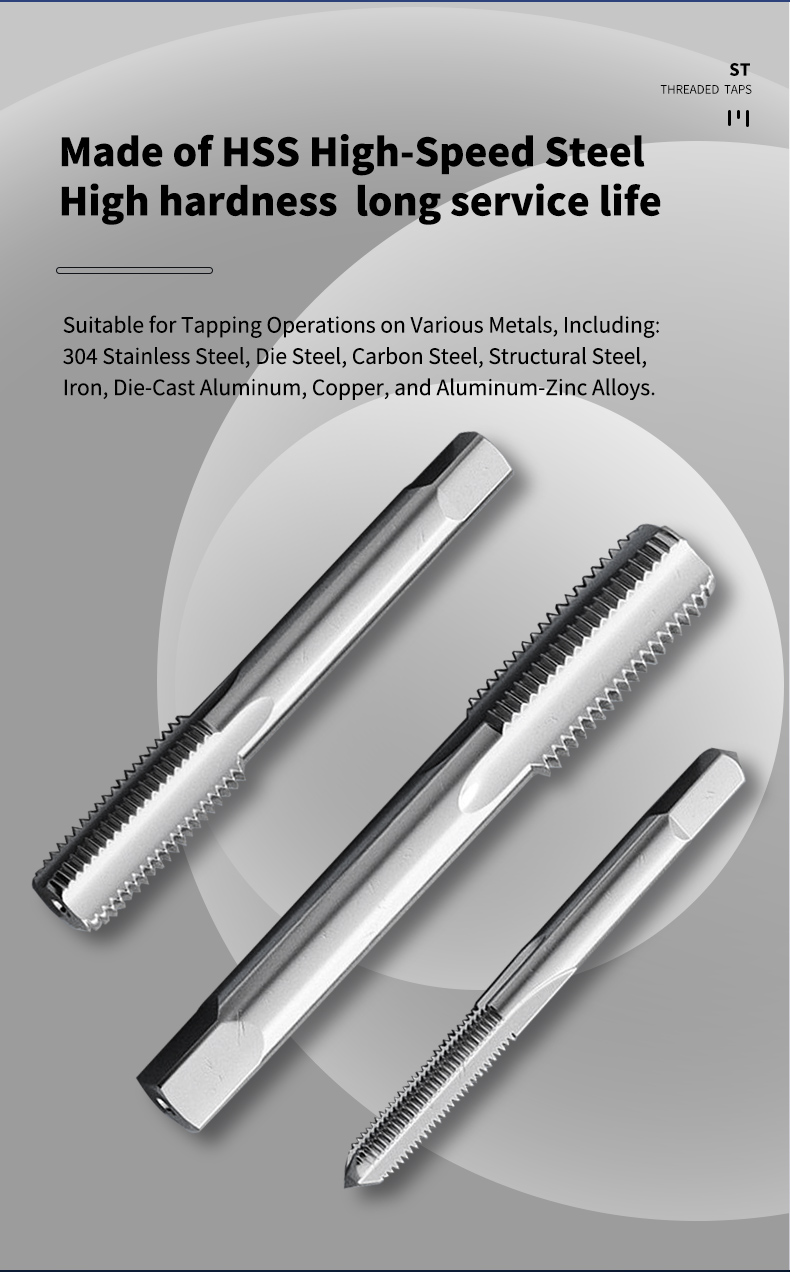

Taper Material: 6542 High-Speed Steel

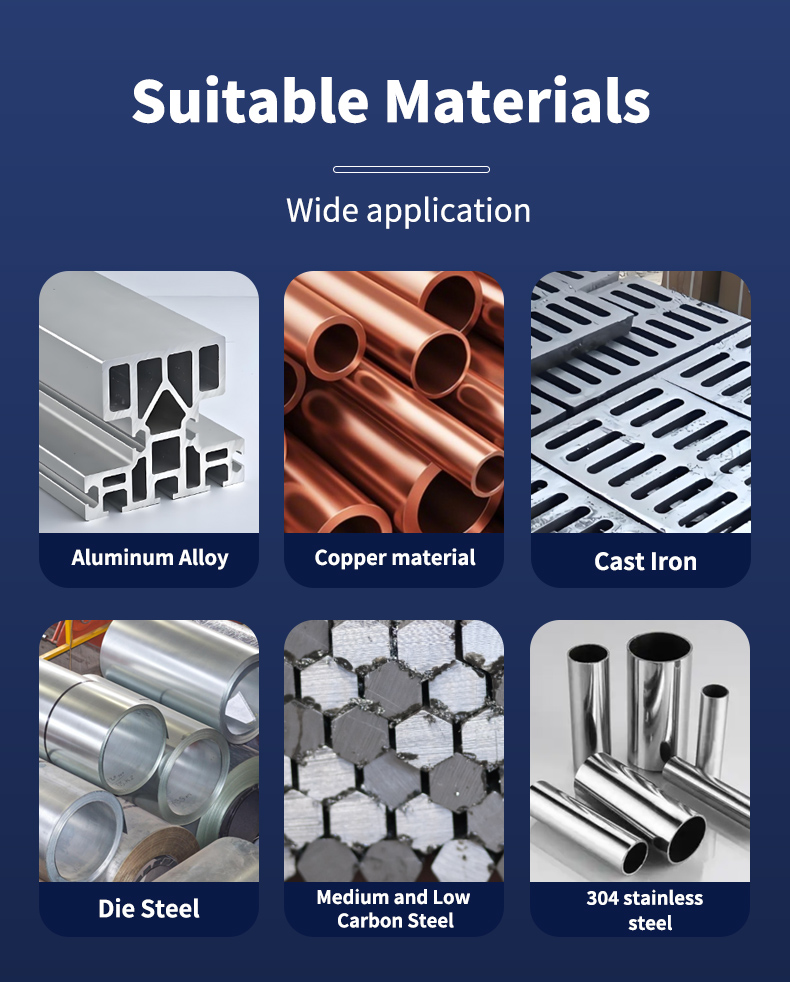

Applications: Suitable for drilling machines, tapping machines, automatic machine tools, CNC machining centers, milling machines, etc.

Due to the high hardness of high-speed steel machine taps, hand use and electric drills are not recommended.

Precautions: Tapping

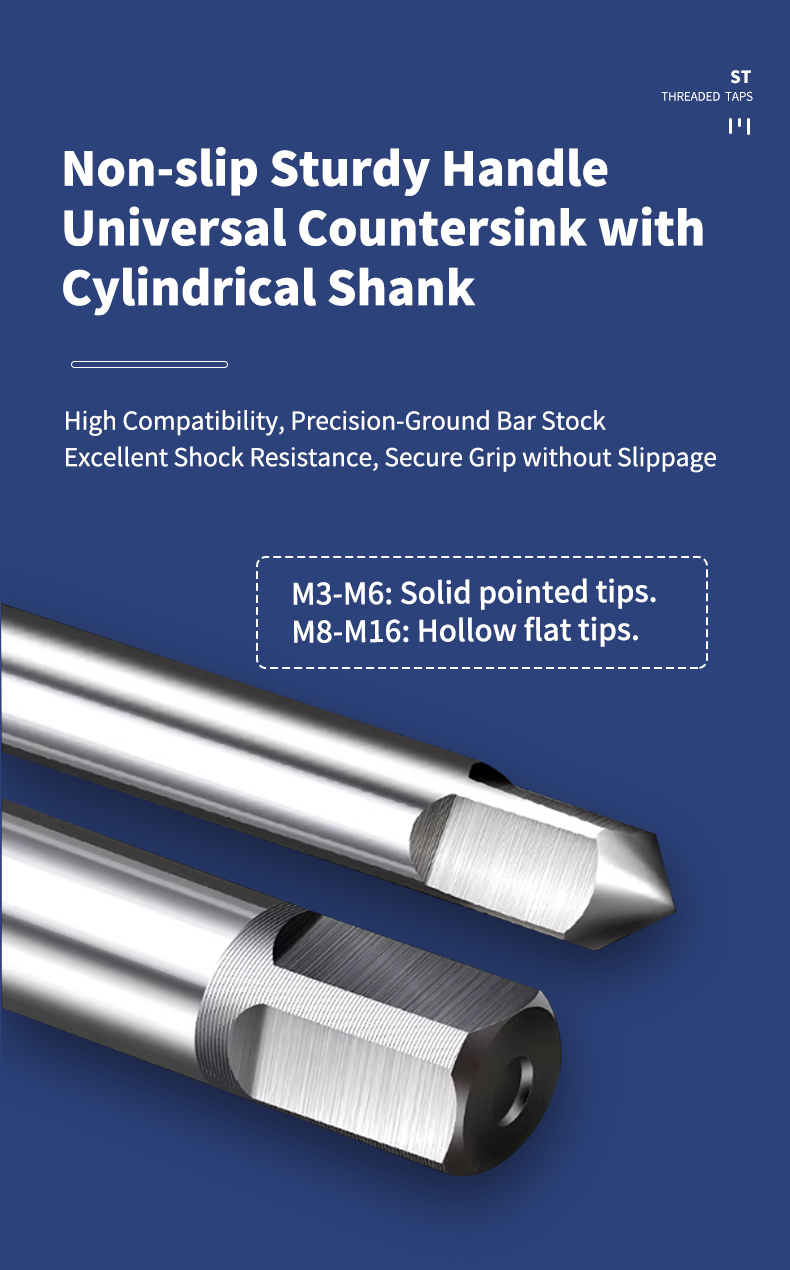

International Standards: ST1.2-ST5 have pointed shanks (the pointed tip can be ground flat). ST6 and above have flat tips.

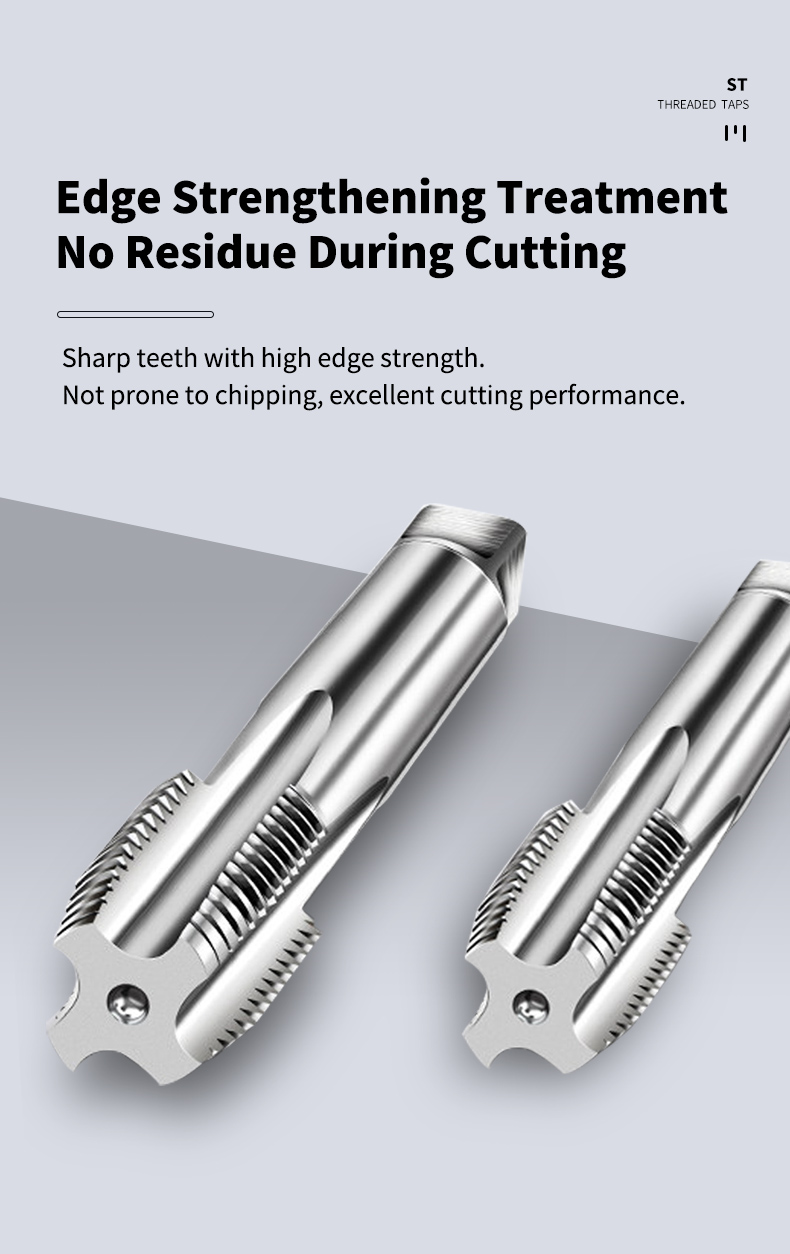

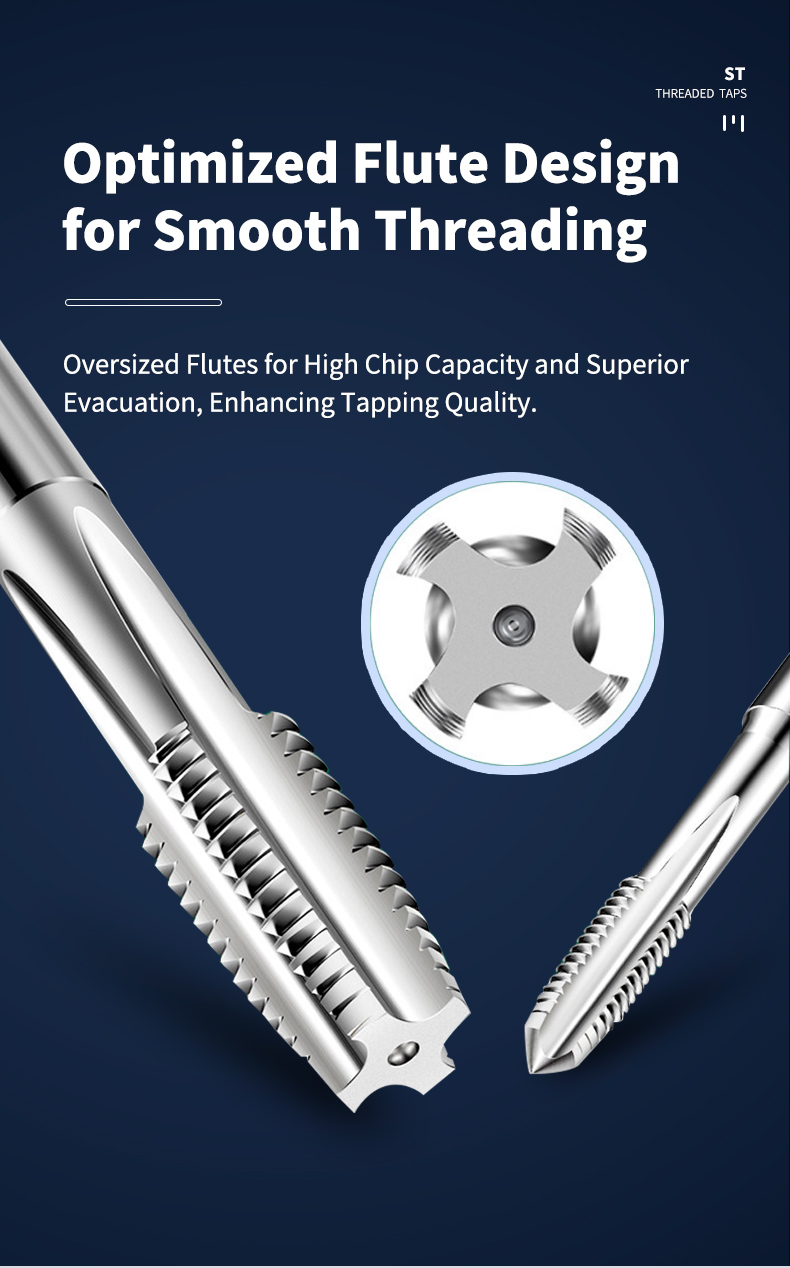

6542 High-Speed Steel: Significantly improves the toughness and wear resistance of the product. Product Description: Performance, Drill: Cobalt-containing tool steel significantly improves the wear resistance and cutting performance of steel. Titanium: Increases strength and has good heat resistance, low-temperature toughness, and fracture toughness.

Special taps for wire thread inserts (abbreviated as ST taps, thread insert taps, or threaded insert taps) are used for machining internal threads for installing wire thread inserts. Compared to ordinary taps, ST taps have a larger major diameter, pitch diameter, and minor diameter than the diameter of the thread insert.

Reasons for premature tap breakage:

1. Proper tap selection: Tap selection must be based on the workpiece material and hole depth.

2. Inappropriate pilot hole diameter: For example, for ST5*0.8, a 5.2mm pilot hole diameter should be used; using a 4.0mm pilot hole will lead to breakage.

3. Workpiece material issues: Impure material, hard spots, or porosity can cause the tap to lose balance and break.

4. Poor cutting fluid quality:Problems with the quality of cutting fluid or lubricating oil will affect thread accuracy and tap life.

5. Blind hole impact with the pilot hole: When machining blind hole threads, the operator may not realize the tap is about to contact the bottom of the hole.