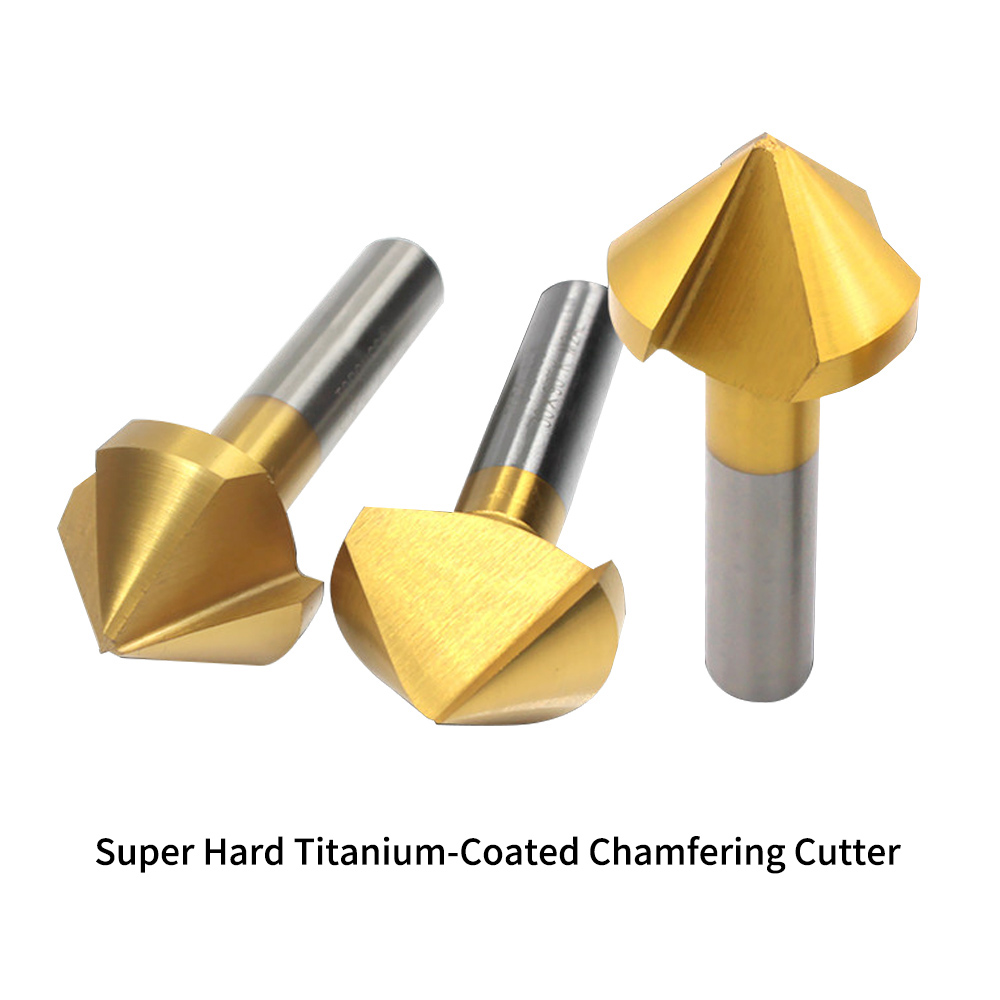

Titanium-plated 60°/120° straight shank cobalt chamfering knife

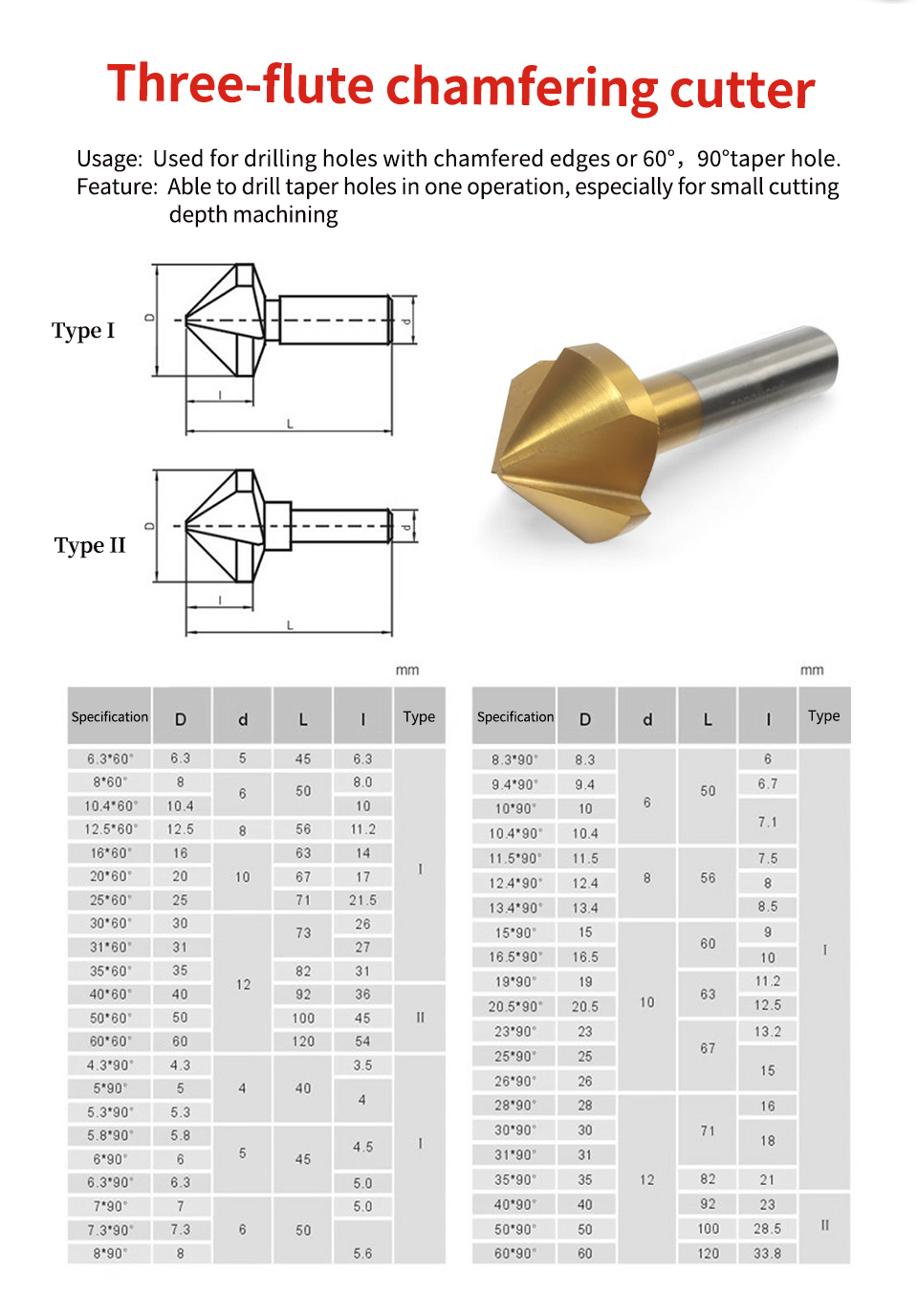

1.60° & 120° angles in one pass – eliminates secondary chamfering or spotting.

2.Titanium-plated HSS body + 5% Co substrate – TiN layer adds 30 % wear resistance, anti-weld on stainless, aluminum or mild steel.

3.3-flute 60° option – balanced cutting, triple feed rate, smooth finish Ra ≤1.6 µm.

4.1-flute 120° option – wide land for large screw heads, low thrust, chatter-free on thin plates.

5.Straight shank h6 – zero run-out on ER, JT, Weldon arbors; Ø6-60 mm range covers M3-M36 clearances.

6.Cross-hole pilot – self-centers on curved/angled faces, drills right to corners.

7.Internal coolant-ready (7 MPa) – flushes chips, extends edge life 25 %, prevents burn.

8.One-pass rounding & trimming – deburr, countersink and edge-break in a single plunge, cutting cycle time 40 %.

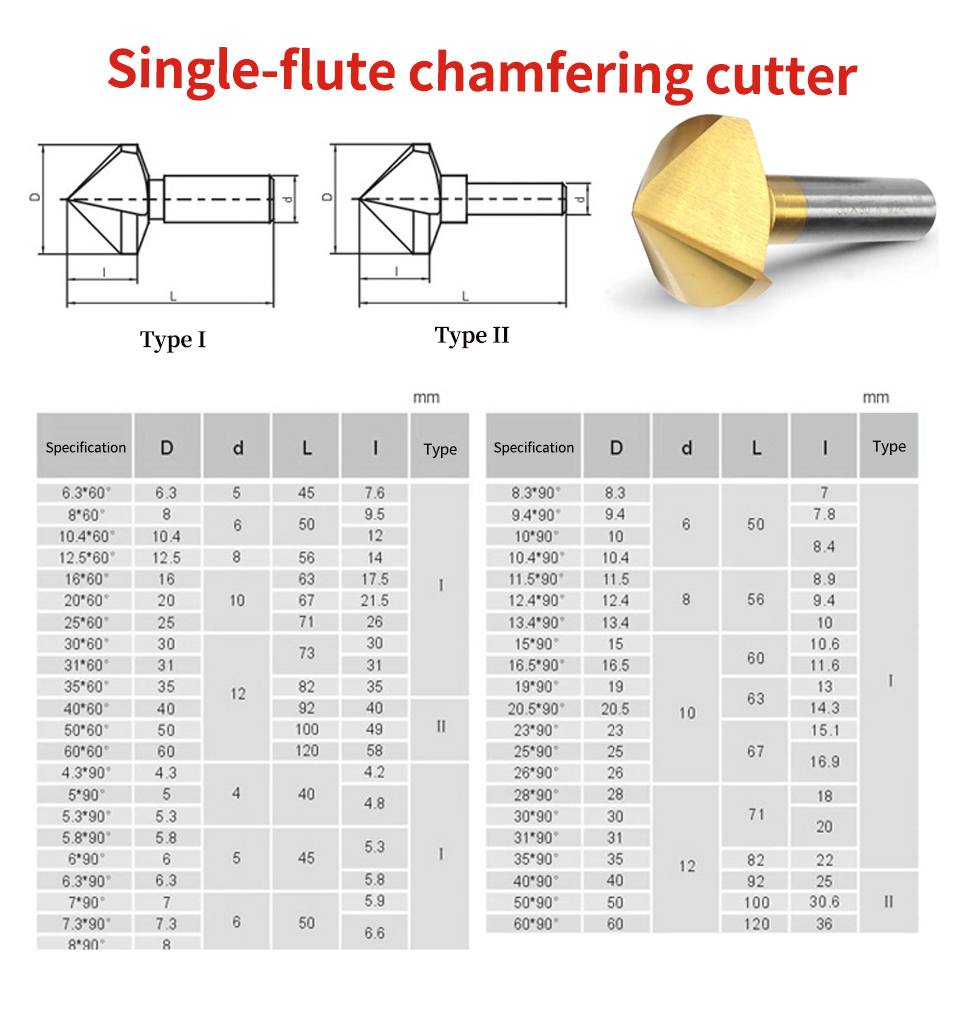

Single-flute/Triple-flute Straight Shank Chamfering Tool

Name: Straight Shank Chamfering Tool

Material: Cobalt-plated titanium high-speed steel

Hardness: HRC62-64°

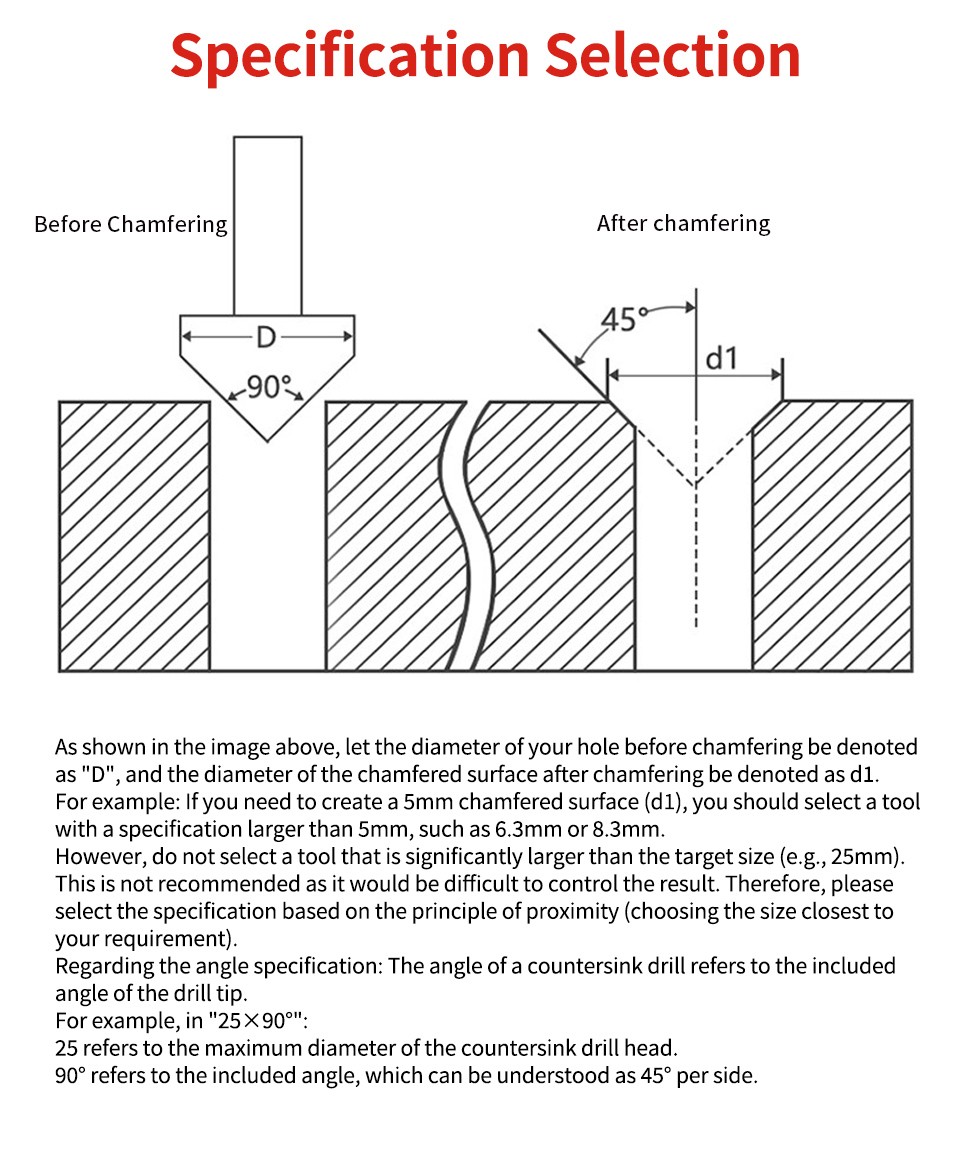

Angle: 60°, 90°, 120°

Application: Used for chamfering or taper machining of round holes in stainless steel, steel, iron, copper, aluminum, etc.

Features: Taper machining can be completed in a single pass, suitable for machining with small depths of cut.

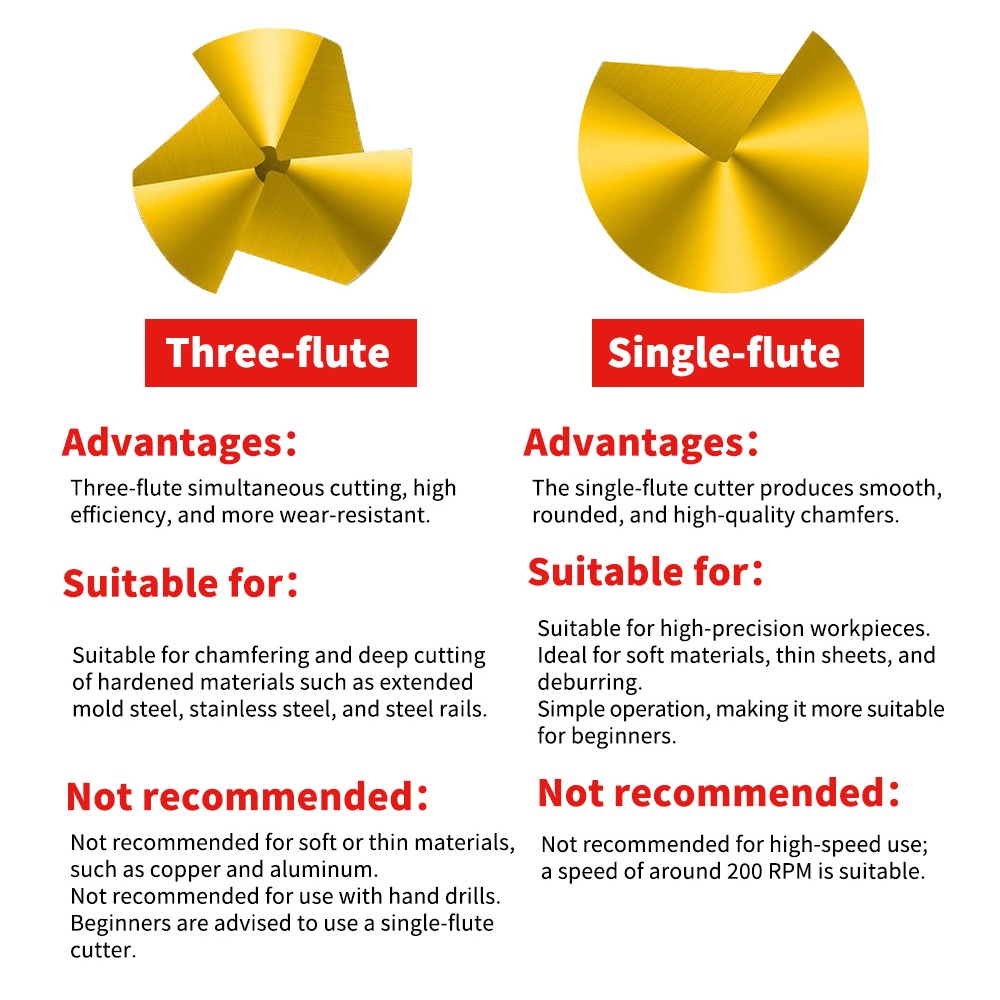

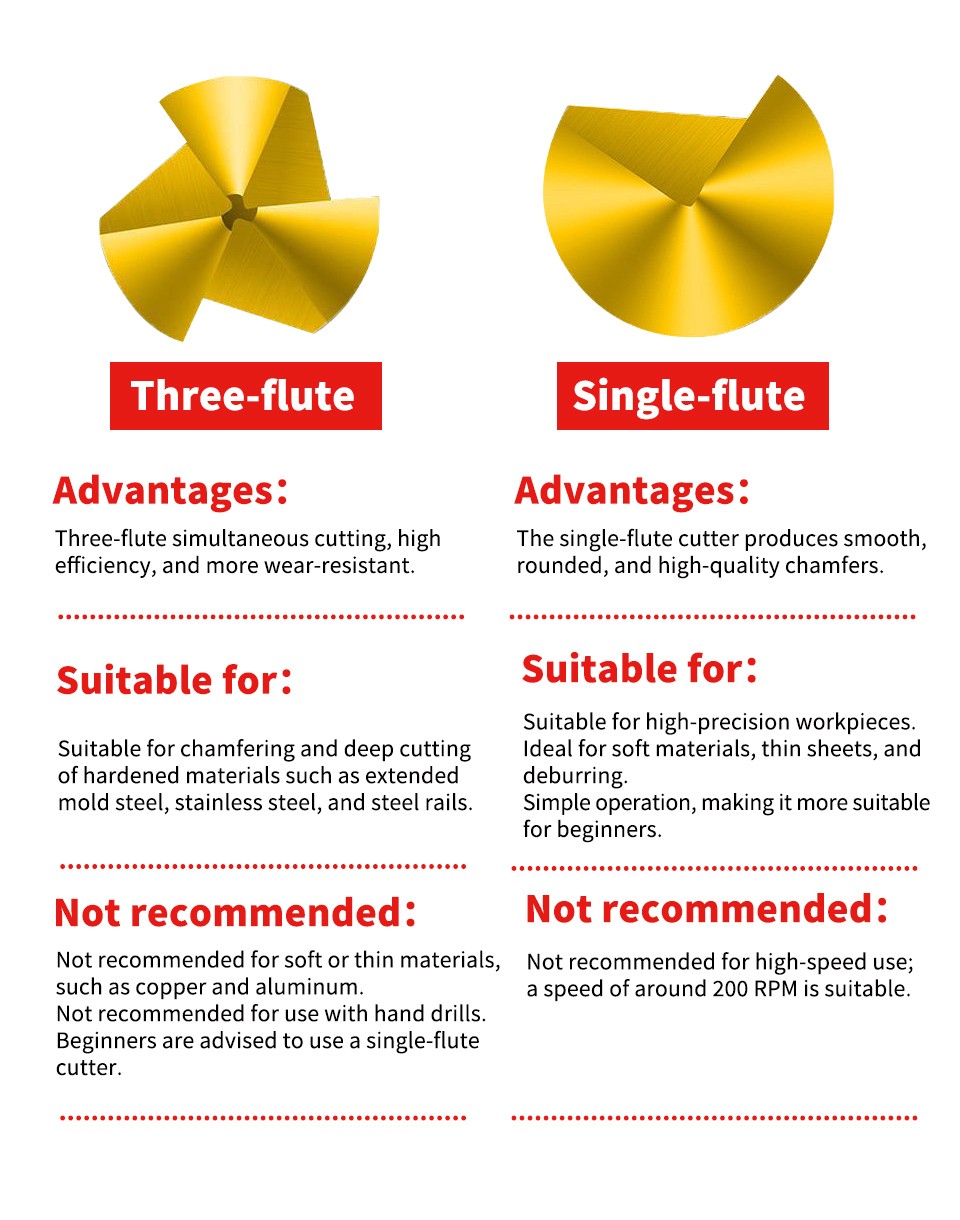

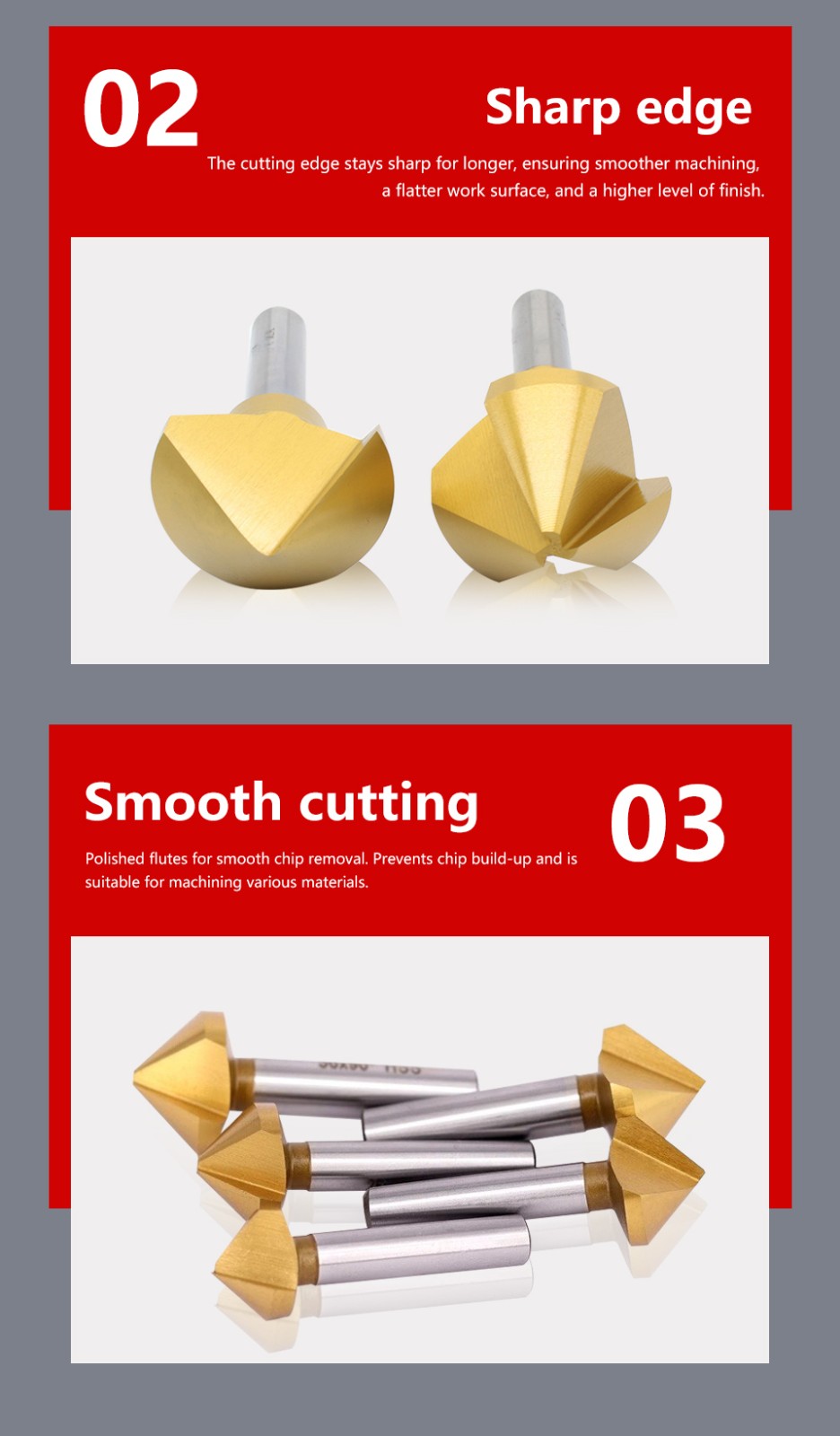

Single-flute: Suitable for soft materials, only one cutting edge bears the force, resulting in a smoother chamfer. Suitable for softer materials such as aluminum, but slightly less efficient than three-flute.

Triple-flute: Suitable for hard materials, three cutting edges bear the force evenly, with each cutting edge experiencing less stress, thus more durable and more efficient.

Use with caution:

Triple-edge geometry is extremely sharp and designed for high-precision machining centers only. Vibration or damage may occur if used with ordinary bench drills or hand-held electric drills.

Do not use on brittle materials such as ceramic tiles, concrete, stone, or walls.