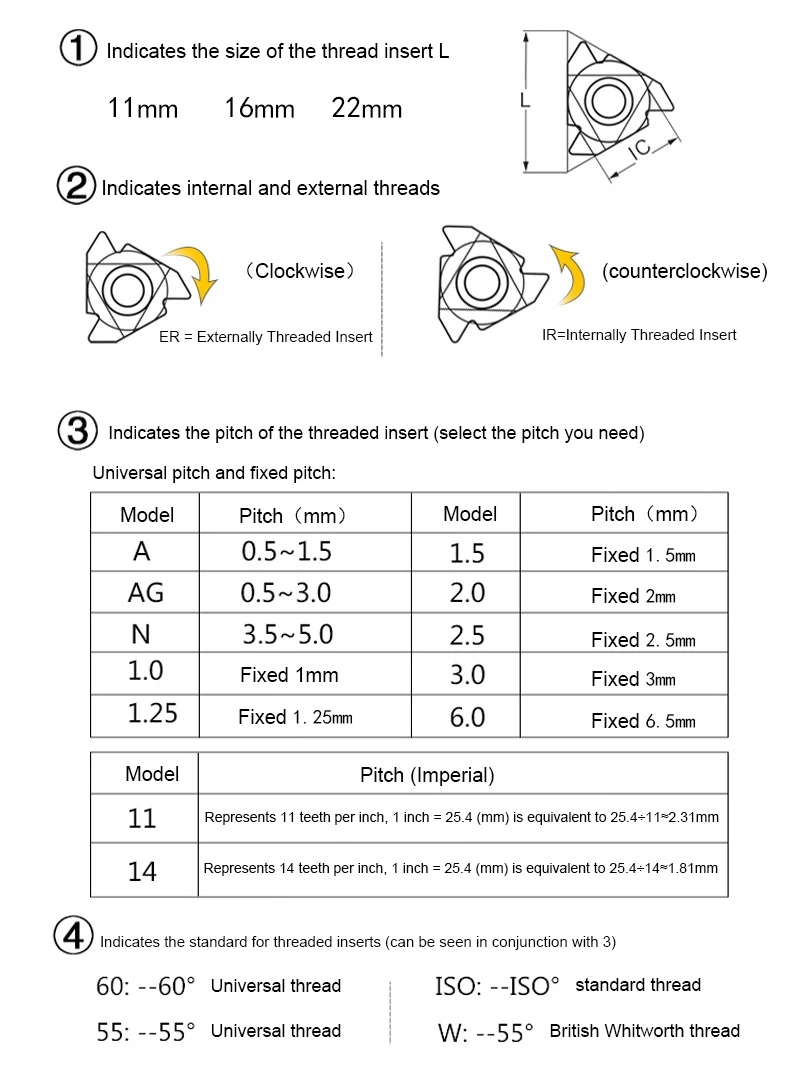

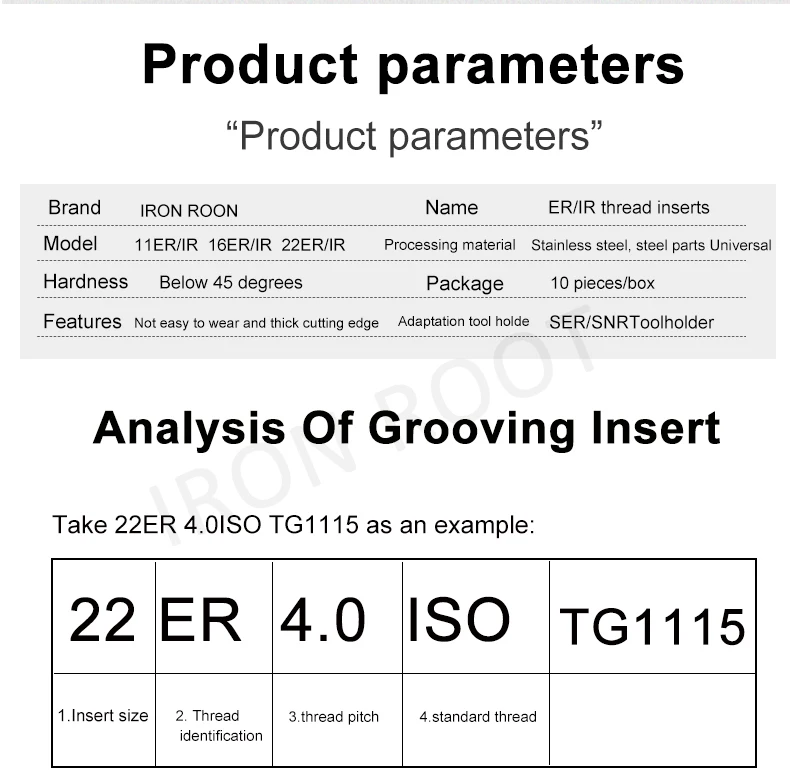

22ER/22IR 4.0-6.0ISO Thread CNC Tools Carbide Inserts for N55/N60 Thread Turning

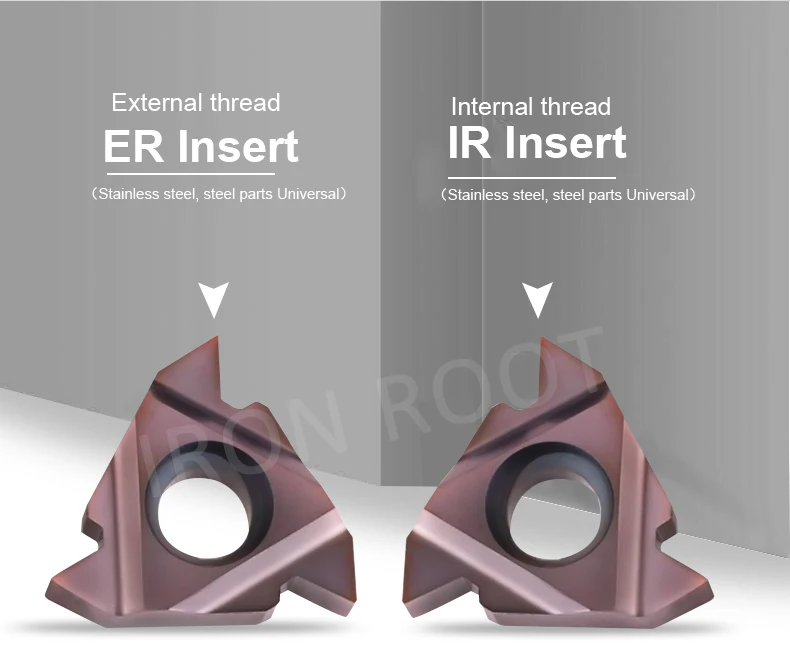

ER/IR thread inserts offer multiple advantages.

They ensure high-precision threading in various materials, minimizing the risk of thread damage or failure.

With excellent corrosion resistance and wear durability, these inserts maintain performance even in harsh environments. Their easy installation and removal save time and labor costs, while the standardized design guarantees compatibility with different applications. Moreover, the inserts enhance the strength and reliability of threaded connections, making them ideal for industries requiring robust and long-lasting solutions.

Product Details

22ER/IR Thread Inserts: Revolutionizing Threaded Connections

In the ever-evolving landscape of industrial fasteners, ER/IR thread inserts have emerged as a game-changer, offering a plethora of benefits that are transforming how industries approach threaded connections.

These thread inserts are engineered to deliver unparalleled precision threading, a critical factor in maintaining the integrity of assemblies across diverse materials. Whether it's in soft plastics, lightweight composites, or high-strength metals, ER/IR thread inserts ensure consistent, reliable threads that can withstand heavy loads and vibrations. This precision not only reduces the likelihood of thread stripping or failure but also enhances the overall quality and lifespan of products.

One of the standout features of ER/IR thread inserts is their remarkable durability. Built with corrosion-resistant materials, they can endure exposure to harsh chemicals, extreme temperatures, and moisture, making them ideal for applications in industries such as automotive, aerospace, and marine, where components are constantly challenged by tough environmental conditions. Their wear-resistant properties further contribute to long-term performance, minimizing the need for frequent replacements and reducing maintenance costs significantly.

Installation and removal of ER/IR thread inserts are a breeze, thanks to their user-friendly design. This simplicity streamlines production processes, allowing manufacturers to save valuable time and labor resources. The standardized design of these inserts also ensures seamless compatibility with a wide range of equipment and applications, providing flexibility and convenience for various projects.

The impact of ER/IR thread inserts extends beyond individual components. By strengthening threaded connections, they enhance the reliability and safety of entire systems, reducing the risk of equipment failures and potential hazards. As industries increasingly prioritize efficiency, durability, and cost-effectiveness, ER/IR thread inserts are quickly becoming the go-to solution for threaded fastening needs, marking a new era in industrial connectivity.

Leave your messages