DNMG CNC Turning Insert Cutting Tools for Steel Stainless Steel

Shape: It features a diamond - shaped (DN) geometry. This shape offers multiple cutting edges, allowing for efficient use and extended tool life. The diamond shape also provides good chip control, which is crucial when machining steel and stainless steel, as these materials can produce long and stringy chips.

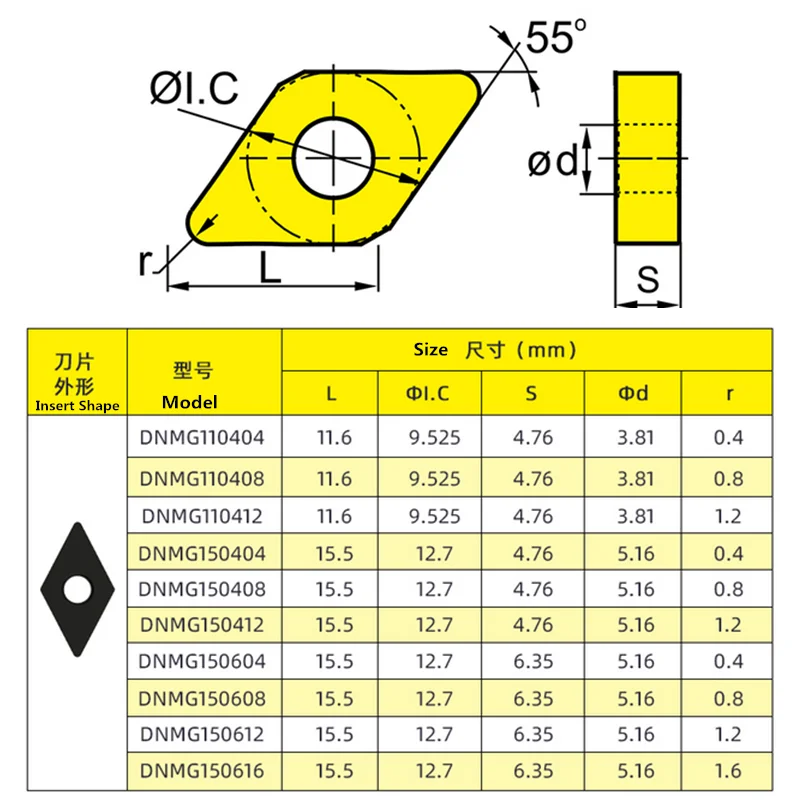

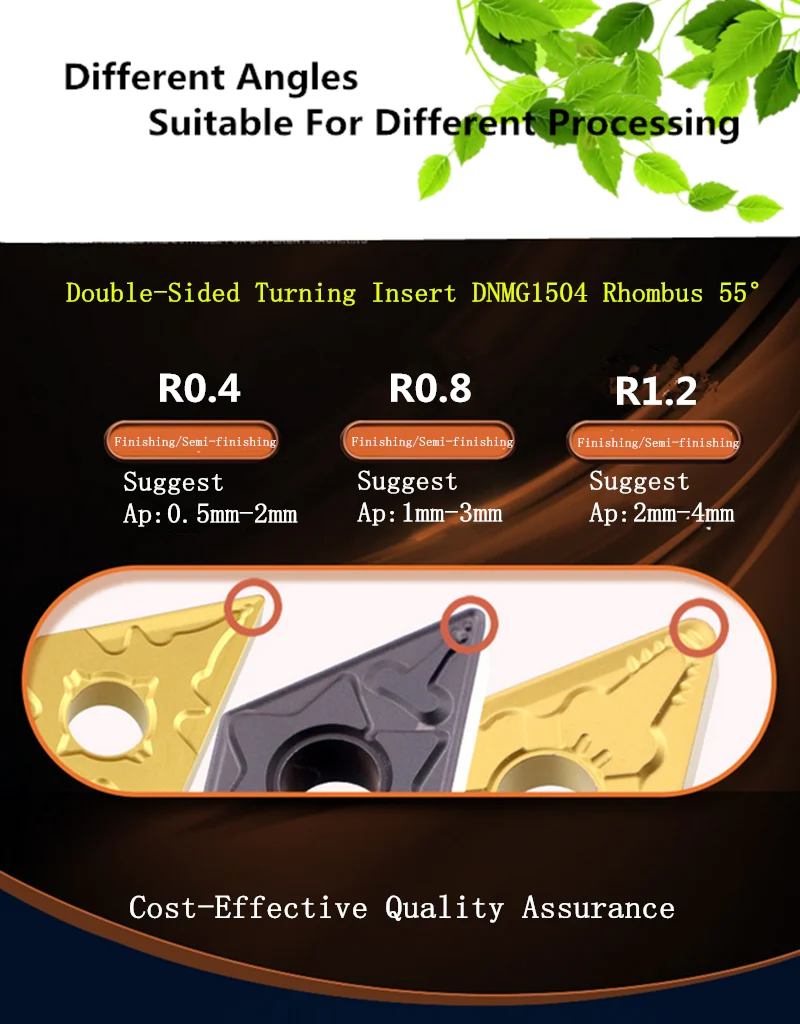

Size: With a side length of 15.875mm, a thickness of 4.76mm, and a nose radius of 0.4mm. The 15.875mm side length provides a good balance between cutting edge strength and the ability to reach into complex part geometries. The 4.76mm thickness ensures the insert can withstand the high cutting forces encountered during steel and stainless - steel machining. The 0.4mm nose radius is suitable for a variety of applications, including both roughing and finishing operations, as it can produce a relatively smooth surface finish while still maintaining good edge strength.

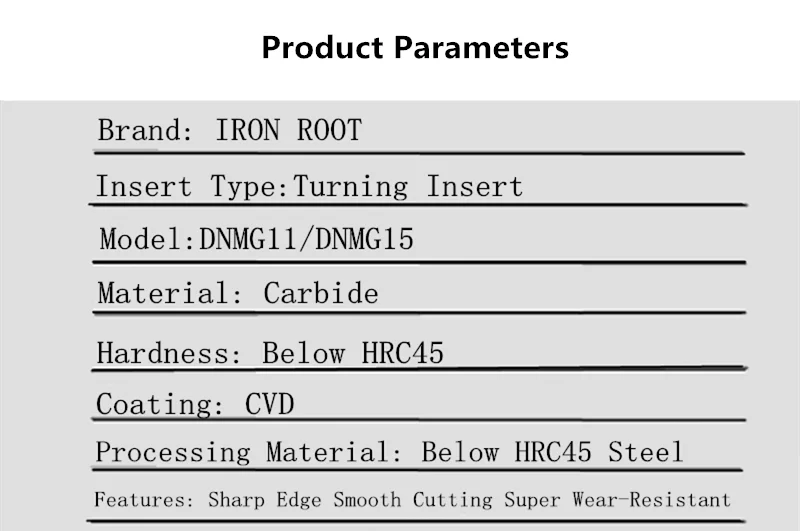

Accuracy: The "M" in DNMG indicates a medium - tolerance class. This level of accuracy ensures consistent performance and reliable machining results. It allows for precise control over the cutting process, which is essential for achieving tight tolerances in steel and stainless - steel parts manufacturing.

Carbide Substrate: The insert is made from high - quality carbide material. Carbide offers excellent hardness, which is necessary for effectively cutting through the tough and hard - to - machine steel and stainless - steel materials. The high hardness of the carbide substrate enables the insert to maintain a sharp cutting edge for an extended period, reducing the frequency of tool changes and increasing overall productivity.

"HM" Coating or Treatment: The "HM" designation likely refers to a specific coating or material treatment. This coating is engineered to enhance the insert's performance when machining steel and stainless steel. It may have properties such as increased wear resistance, reduced friction, and improved heat dissipation. For example, some coatings in this category can prevent the formation of built - up edges (BUE) when machining stainless steel, which is a common problem due to the stickiness of stainless - steel materials. The coating also helps to protect the carbide substrate from the high temperatures generated during cutting, thereby extending the tool's lifespan.

High Wear Resistance: Thanks to its carbide construction and the HM - related enhancements, the DNMG150404 - HM insert can endure significant wear during continuous or intermittent cutting of steel and stainless steel. This makes it suitable for high - volume production runs where tool life is a critical factor.

Good Chip Control: The diamond shape and the specific geometry of the insert are optimized for effective chip breaking and evacuation. When machining steel and stainless steel, proper chip control is essential to prevent chip entanglement, which can lead to surface defects on the workpiece and premature tool wear. The insert's design ensures that chips are broken into manageable sizes and are efficiently removed from the cutting zone.

Stability in Machining: The insert's physical properties and geometry contribute to stable machining. It can withstand the high cutting forces and vibrations associated with steel and stainless - steel machining, resulting in improved surface finish and dimensional accuracy of the machined parts. This stability is crucial for achieving the tight tolerances often required in industries such as automotive, aerospace, and medical, where steel and stainless - steel components are widely used.

Steel Machining: It is highly effective for machining various types of steel, including carbon steel, alloy steel, and tool steel. Whether it is roughing operations to quickly remove large amounts of material or finishing operations to achieve a smooth surface finish, the DNMG150404 - HM insert can deliver excellent results. For example, in the manufacturing of shafts, gears, and other steel components, this insert can be used in both turning and facing operations.

Stainless - Steel Machining: Stainless steel, with its unique properties such as corrosion resistance and high strength, can be challenging to machine. However, the DNMG150404 - HM insert is well - equipped to handle these challenges. It can be used in the production of stainless - steel pipes, fittings, and components for industries such as food and beverage, chemical processing, and marine, where stainless steel is widely used due to its corrosion - resistant properties.