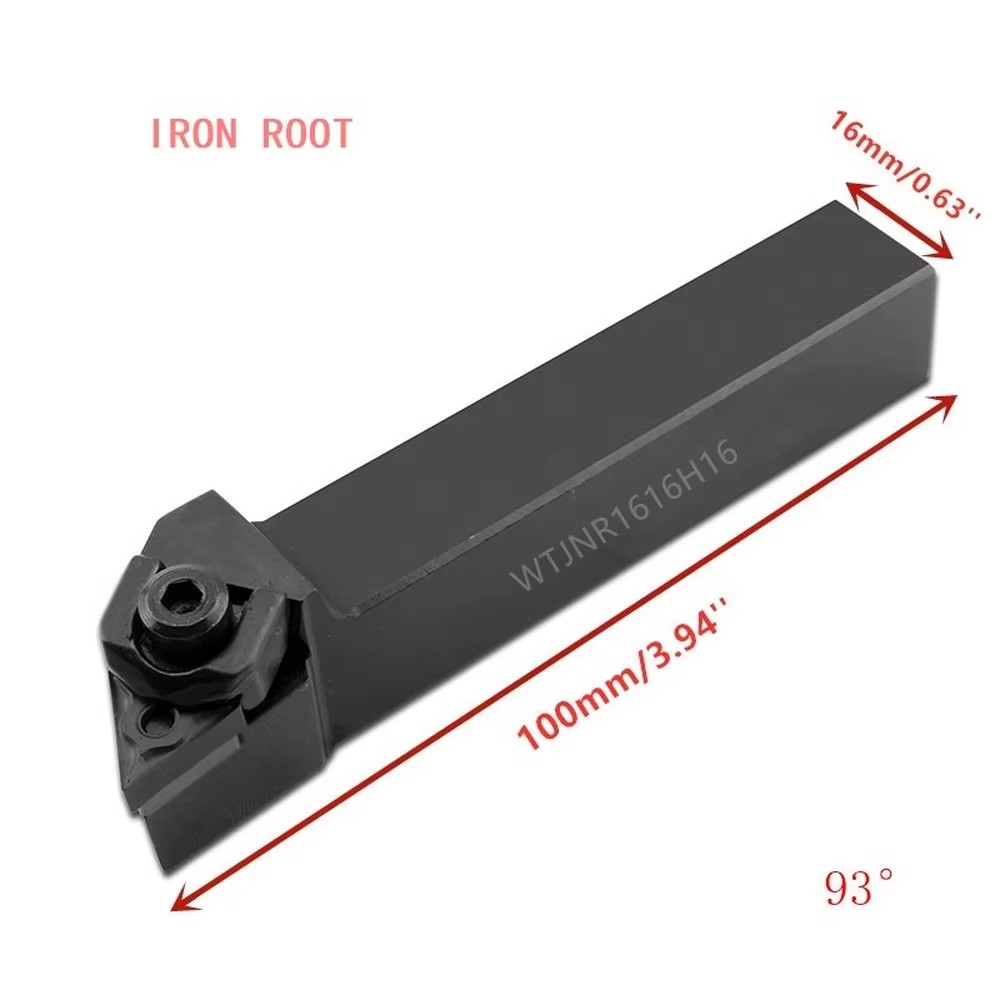

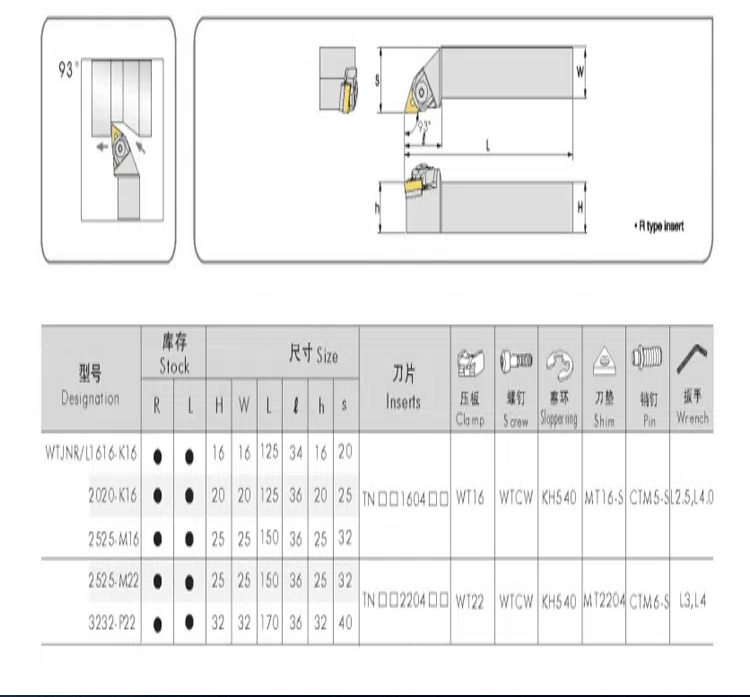

93° CNC external cylindrical tool bar WTJNR1616 WTJNR2020 large platen triangular turning tool

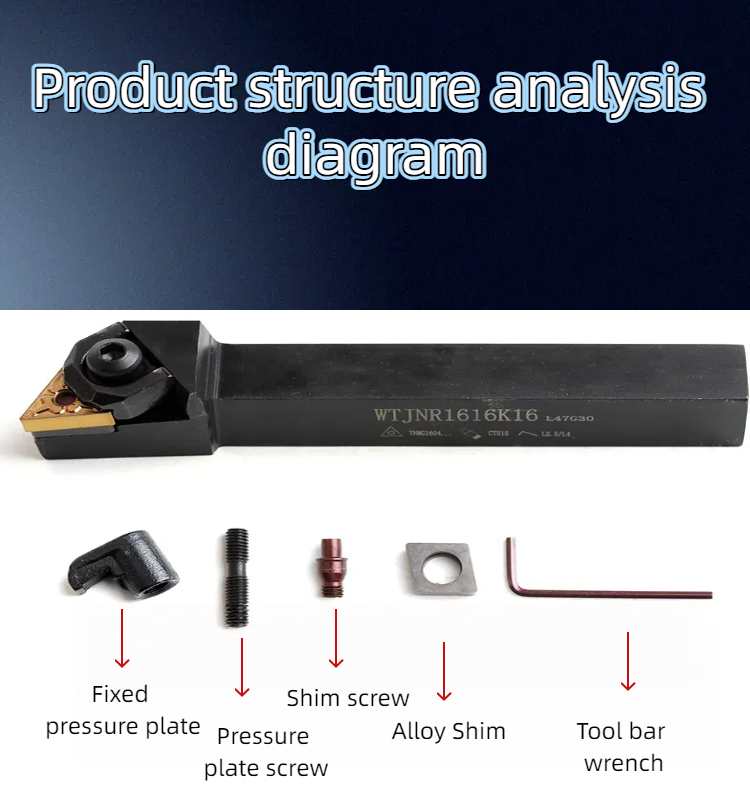

1. Easy installation of the blade: The blade is fixed with a large pressure plate. You only need to loosen the pressure plate screw to install and remove the blade. There is no need to loosen the center screw. This can reduce the probability of damage to accessories and make the tool bar more durable.

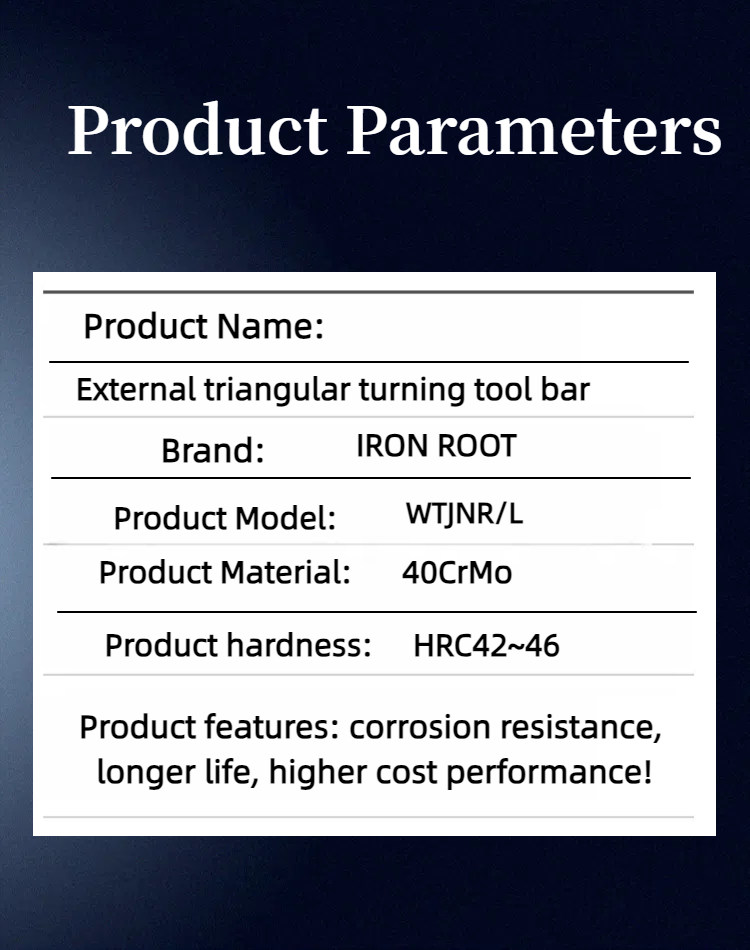

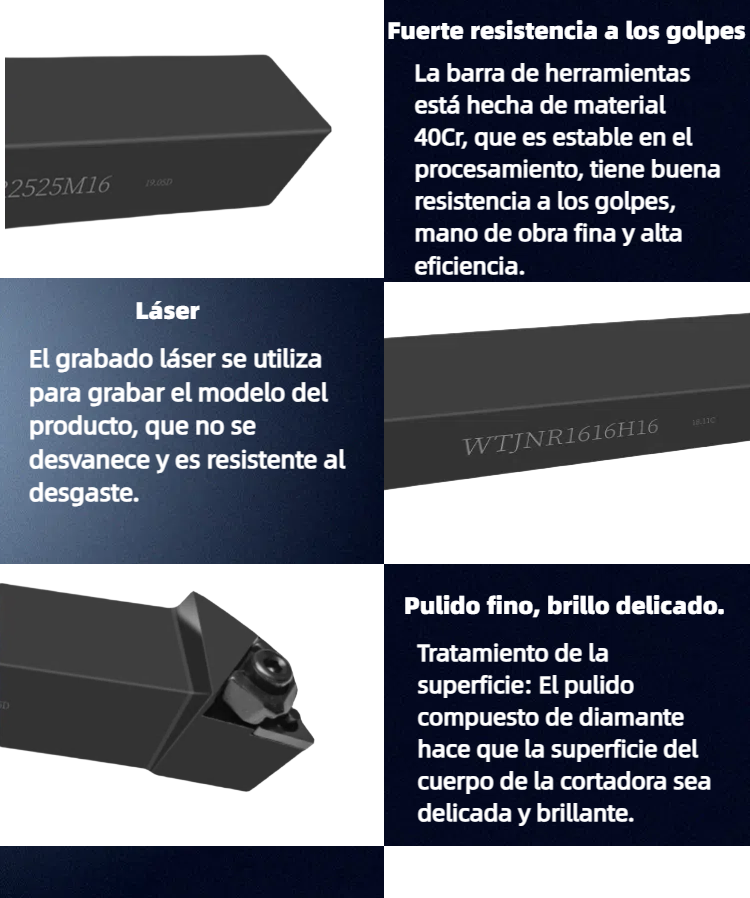

2. Excellent material performance: Generally, 42 chromium-molybdenum alloy steel is selected and overall heat treated, with a hardness of 45-48 degrees. This material gives the tool bar higher strength and rigidity, can withstand greater cutting forces, and is suitable for high-intensity heavy processing and cutting.

3. Reasonable pressure plate design: The pressure plate design has good stability, can effectively protect the blade during the cutting process, has strong impact resistance, and thus increases the service life of the blade. The blade is usually designed to be double-sided.

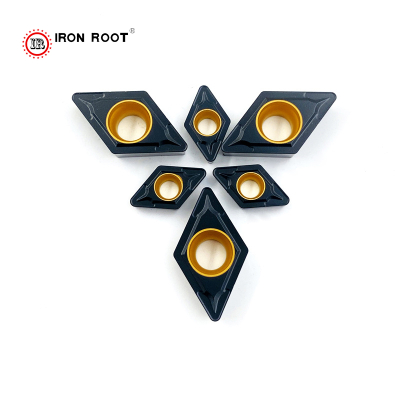

4. Indexable blade: The blade does not undergo high-temperature welding, which avoids defects such as decreased blade hardness and cracks caused by welding, and improves the durability of the tool. At the same time, the tool bar can be reused, which saves steel and improves the utilization rate of the blade.

Pressure plate structure: adopts a large pressure plate design, and the blade is fastened by the pressure plate and screws. This structure makes the installation and removal of the blade more convenient. You only need to loosen the pressure plate screw to load and unload the blade, without loosening the center screw, which reduces the operation steps, improves work efficiency, and also reduces the probability of damage to accessories.

Accurate positioning: Some advanced designs will be equipped with blade positioning components, such as setting a positioning piece accommodating groove on the side wall of the tool bar installation groove, and there are positioning blocks and compression springs in the groove. When installing the blade, the positioning block can be inserted into the positioning groove on the side of the blade to play a precise positioning role and prevent the blade from falling off during installation.

Stable locking: Some tool bars are also equipped with a locking component located at the rear of the fixed pressure plate. For example, through components such as locking blocks and pull rods, after the fixed pressure plate presses the blade, the locking block can be inserted into the locking groove on the surface of the tool bar to prevent the fixed pressure plate from being offset due to vibration and other reasons during processing, further improving the stability of the connection between the blade and the tool bar.