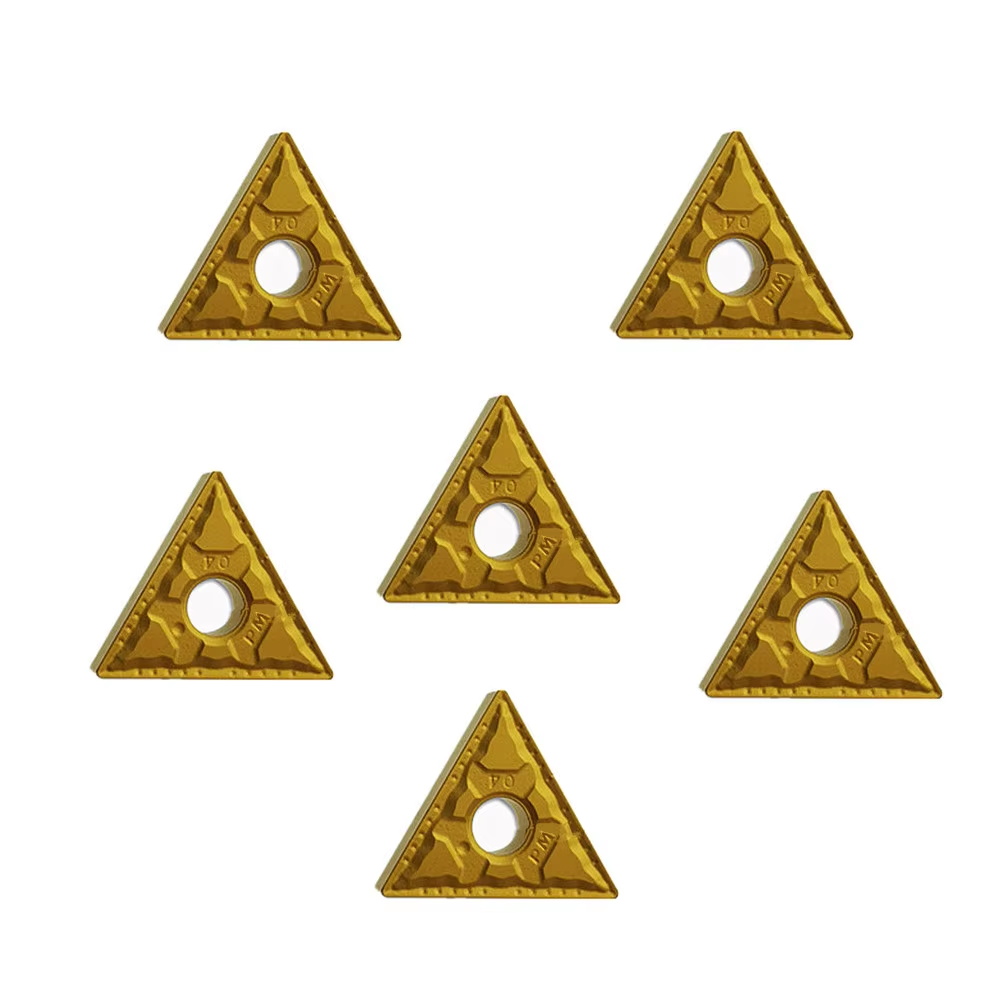

TNMG220408-PM/04-PM Tungsten Carbide Turning Inserts | for Steel CNC Lathe

Exceptional wear resistance and hardness, ensuring long tool life even in heavy-duty steel machining.

Optimized IRON ROOT TNMG geometry with negative rake angle reduces cutting resistance, enabling stable high-speed CNC operations.

PM-grade micrograin carbide substrate enhances edge retention and minimizes friction for consistent precision.

Versatile performance: IRON ROOT TNMG220408-PM excels in roughing/semi-finishing, while TNMG220404-PM delivers superior fine finishing with smooth surface finishes.

Compatible with standard TNMG tool holders for quick, secure installation, reducing downtime during tool changes.

Effective chip control prevents buildup, protecting workpieces and maintaining machining efficiency.

Ideal for a wide range of steel grades (low-carbon to alloy steels), ensuring adaptability in diverse CNC lathe applications.

The IRON ROOT TNMG220408-PM and TNMG220404-PM tungsten carbide turning inserts stand as premium solutions tailored for precision steel machining on CNC lathes, combining advanced material science with optimized design to redefine efficiency in turning operations.

The triangular negative rake (TNMG) geometry is a hallmark of their versatility. The IRON ROOT TNMG220408-PM, with its 8mm corner radius, excels in medium to heavy roughing and semi-finishing tasks, efficiently removing material while maintaining stability. In contrast, the IRON ROOT TNMG220404-PM, featuring a 4mm radius, is engineered for fine finishing, delivering exceptional surface quality with tight dimensional tolerances, making it ideal for components requiring precise aesthetics and fit. Both models incorporate a negative rake angle to reduce cutting forces, enabling smooth, high-speed operations even in challenging steel grades.

Designed for seamless integration with standard IRON ROOT TNMG tool holders, these inserts ensure quick, secure installation and alignment, minimizing downtime during tool changes. Their advanced chip-breaking design facilitates efficient chip evacuation, preventing chip entanglement or workpiece damage—critical for maintaining consistent machining accuracy. Whether used in automotive part production, industrial machinery manufacturing, or general steel fabrication, these inserts consistently deliver reliable performance, balancing durability and precision to meet the demands of modern CNC lathe operations.