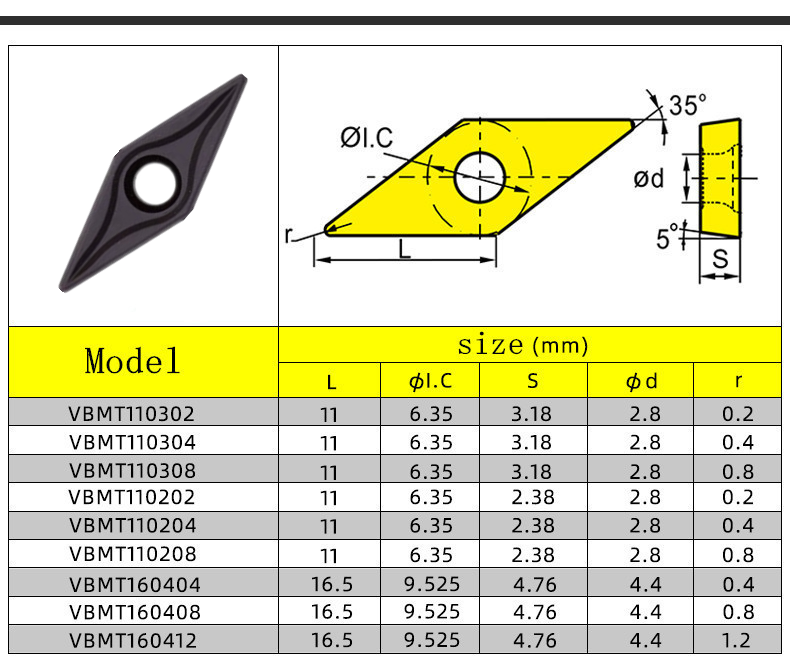

VBMT11 Carbide Insert

1. Geometric design and cutting performance advantages

1.11° back angle optimization

Light cutting force design: suitable for finishing and semi-finishing, reducing the risk of workpiece deformation (especially thin-walled parts), and the surface roughness can reach Ra0.8um.

Strong versatility: compatible with a variety of materials such as steel, stainless steel, cast iron, etc., and adapt to different finish requirements by adjusting the radius of the tool tip arc (such as 0.2mm/0.4mm).

2. Multi-edge economy

. Double-sided 4-edge design (common model): a single blade can be rotated and used 8 times, and the utilization rate is increased by 100% compared with a single-sided blade, reducing the cost per hole.

, Material and coating technology advantages

1. Ultra-fine grain cemented carbide substrate

. Improved wear resistance: The substrate hardness reaches HRA92.5, which is 50% longer than the ordinary blade life (actual data for turning 45# steel) 2. Composite coating technology

. TiAIN+AICrN multi-layer coating: resistant to high temperatures up to 1100℃℃, suitable for high-speed cutting (linear speed up to 250m/min). Low friction coating options: such as DLC coating, which is specially used for anti-built-up edge processing of sticky materials (such as aluminum alloy).

Application scenarios and compatibility

1. Wide range of machine tool adaptation

. Applicable to CNC lathes and milling centers, the tool bar interface standard (such as MCLNR/L series) covers 90% of mainstream models 2. Chip breaker optimization

. Open chip breaker design (such as MF chip breaker): Stable chip control to avoid winding, especially suitable for automated production lines.

VBMT 2(1.5)1 carbide insert is a single-sided, 35° rhombic turning insert with a positive 5° rake angle, designed for medium to finish turning operations.

This insert features two effective cutting edges and is secured via a cylindrical fixing hole with a 40°-60° countersink on one side. It is suitable for a range

of materials and offers a strong cutting edge due to the smaller clearance angle, which is beneficial for small inserts. The VBMT 2(1.5)1 insert is available

in various sizes and coatings