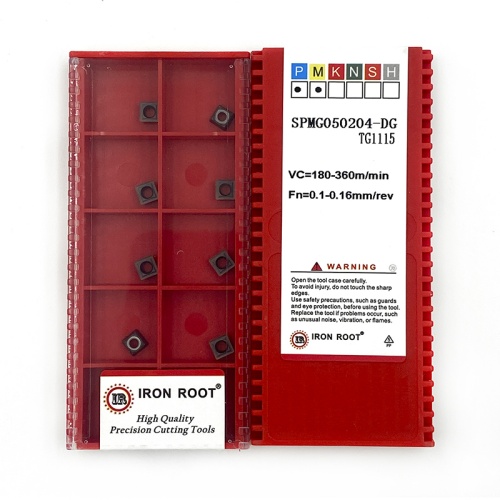

In today's competitive machining industry, selecting a high-performance, durable, and cost-effective cutting tool is crucial for improving production efficiency and reducing costs. The SPMG Series Indexable U Drill Carbide Inserts are designed to meet these demands, offering superior performance in drilling and milling operations for CNC lathes and milling machines.Compared to similar products on the market, the SPMG Series stands out in several key aspects. The unique U-drill design is optimized for high feed rates and deep cutting capabilities, significantly enhancing machining efficiency without compromising precision. This design makes the inserts highly versatile, suitable not only for traditional materials like steel and cast iron but also for challenging materials such as stainless steel and aluminum alloy

![SPMG Series, SPMG Series,]()

![CNC Lathe Inserts CNC Lathe Inserts]()

In terms of material and coating, the SPMG Series uses high-quality tungsten carbide combined with advanced PVD or CVD coating technology. These coatings enhance wear resistance and impact strength while reducing friction and heat generation during machining, thereby extending the life of the inserts. Compared to some competing products, the SPMG Series demonstrates superior durability, maintaining stable performance even under high-load machining conditions.

Moreover, the indexable design of the SPMG Series further enhances its cost-effectiveness. Each insert features multiple cutting edges, allowing users to quickly rotate to a new edge when one wears out, reducing the need for frequent replacements and minimizing downtime. This design not only improves work efficiency but also lowers overall machining costs.

In practical applications, the dimensional accuracy and machining stability of the SPMG Series are strictly controlled. Whether used for drilling, milling, or turning operations, the SPMG Series delivers high-precision results, meeting the stringent quality requirements of modern manufacturing. Compared to some similar products, the SPMG Series offers greater precision and reliability, providing users with a more stable machining experience.

In summary, the SPMG Series Indexable U Drill Carbide Inserts are a high-performance cutting tool that combines efficiency, durability, cost-effectiveness, and precision. They outperform many similar products in terms of performance and offer significant advantages in terms of cost control and longevity. Whether for large-scale manufacturing enterprises or small-to-medium-sized machining workshops, the SPMG Series provides a reliable machining solution to help you improve production efficiency, reduce machining costs, and achieve greater economic benefits.