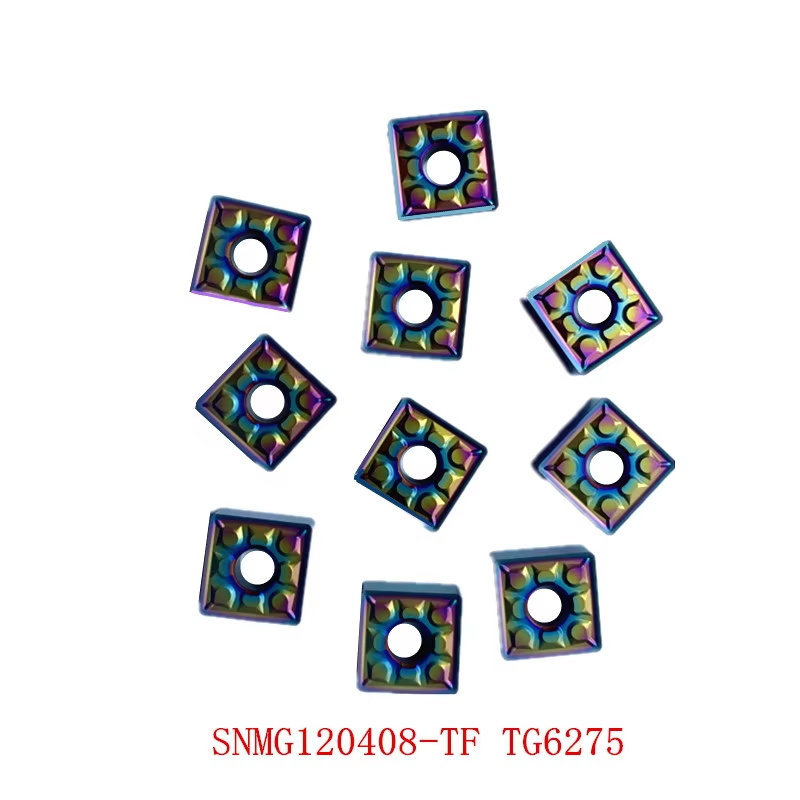

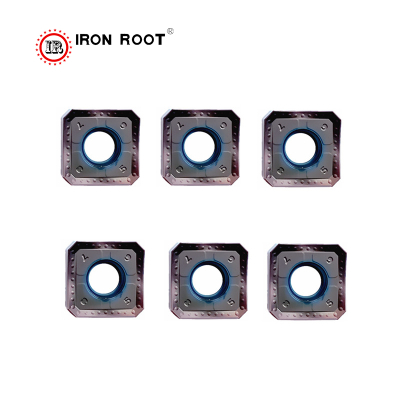

IRON ROOT Cnc Turning Tool SNMG120404-BF2 for Hardened Steel Processing

Ultra-hard & wear-resistant: Premium tungsten carbide withstands high temps/pressures in hardened steel processing, keeping edges sharp longer.

Precise & efficient: 0.4mm corner radius balances sharpness/durability; BF2 chipbreaker prevents tangling, ensuring smooth finishes.

Highly adaptable: Fits most CNC lathes, suits roughing/finishing—ideal for auto, aerospace hardened steel parts.

Product Details

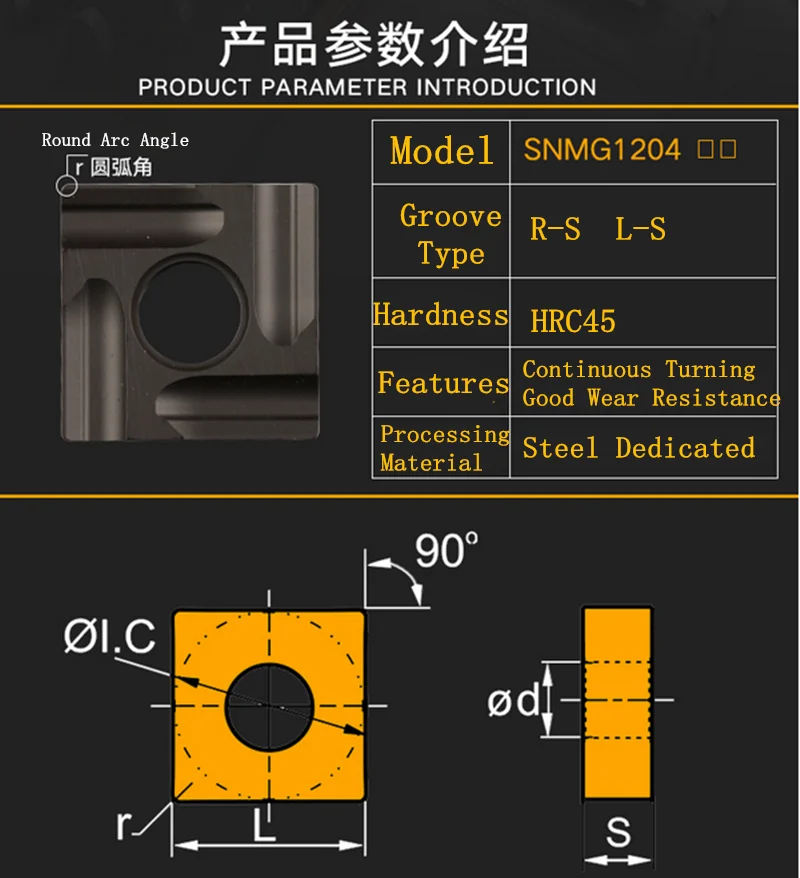

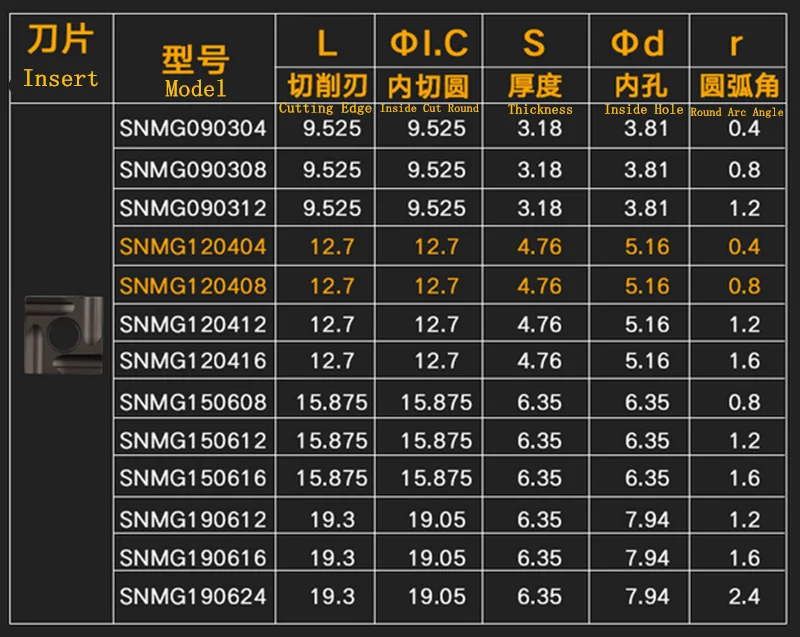

The IRON ROOT SNMG120404-BF2 is a high-performance tungsten carbide turning insert engineered for precision machining of hardened steel. Measuring 12.7mm in side length with a 4.76mm thickness, it features a 0.4mm corner radius optimized for balanced cutting—sharp enough for fine finishes, robust enough for roughing.

Its "BF2" chip-breaking geometry excels at fragmenting tough chips from hardened steel, preventing buildup and tool damage. Crafted from premium tungsten carbide, it resists extreme heat and wear, maintaining edge integrity during prolonged use. Compatible with most CNC lathes, it suits industries like automotive and aerospace, delivering consistent results in both dry and coolant-assisted operations.

Leave your messages