IRON ROOT DNMG150604-HM Turning Insert Cutting Tools for Steel Stainless Steel

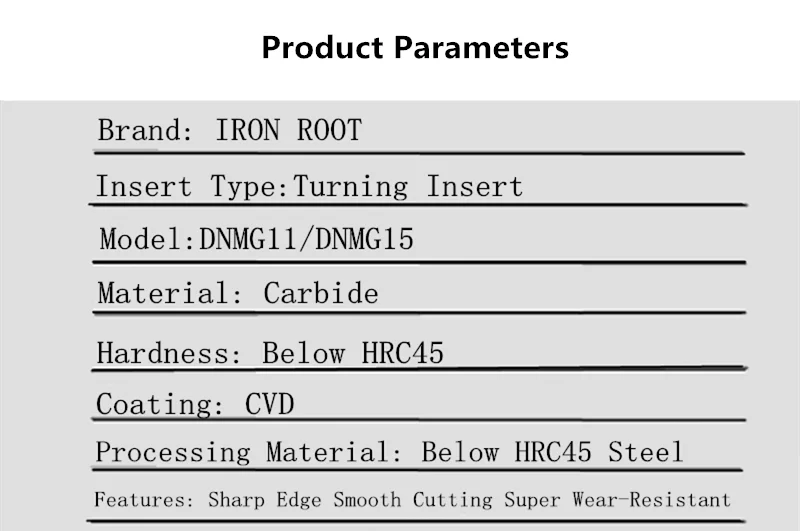

Durable: High-grade carbide resists wear in steel/stainless steel machining, lasting longer.

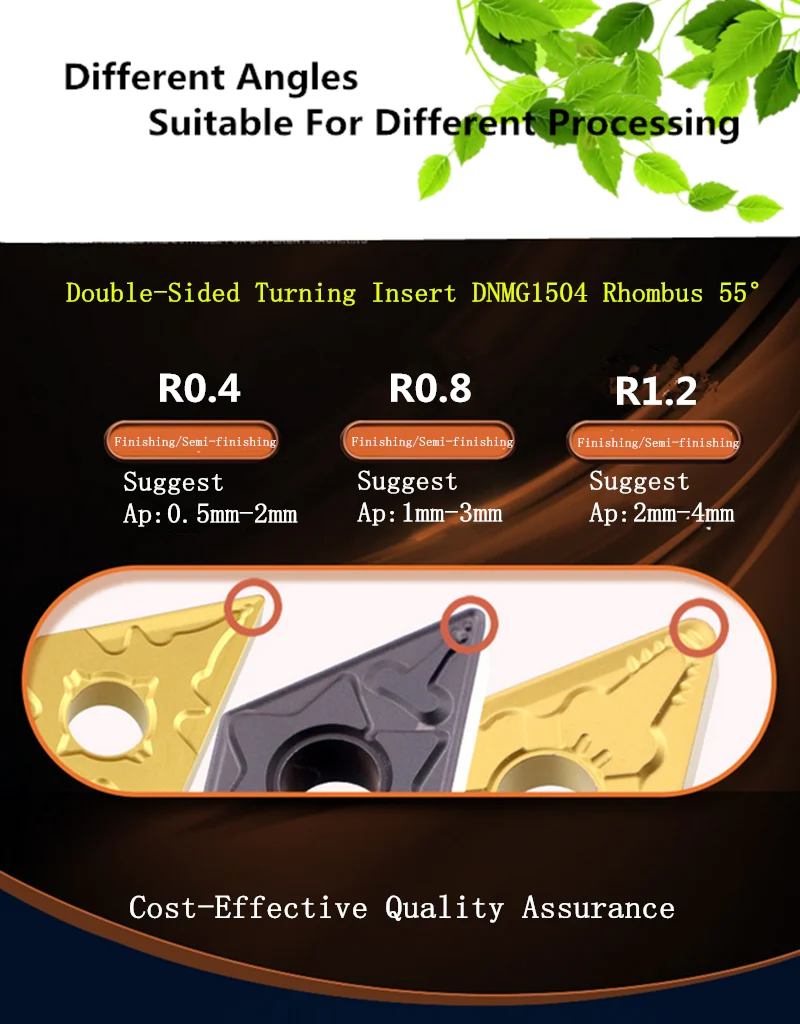

Precise: 0.4mm corner radius ensures smooth finishes; optimized geometry controls chips.

Versatile: Handles roughing/finishing on steel/stainless steel—ideal for auto/aerospace.

Cost-saving: Indexable design lets you rotate edges, reducing replacement needs.

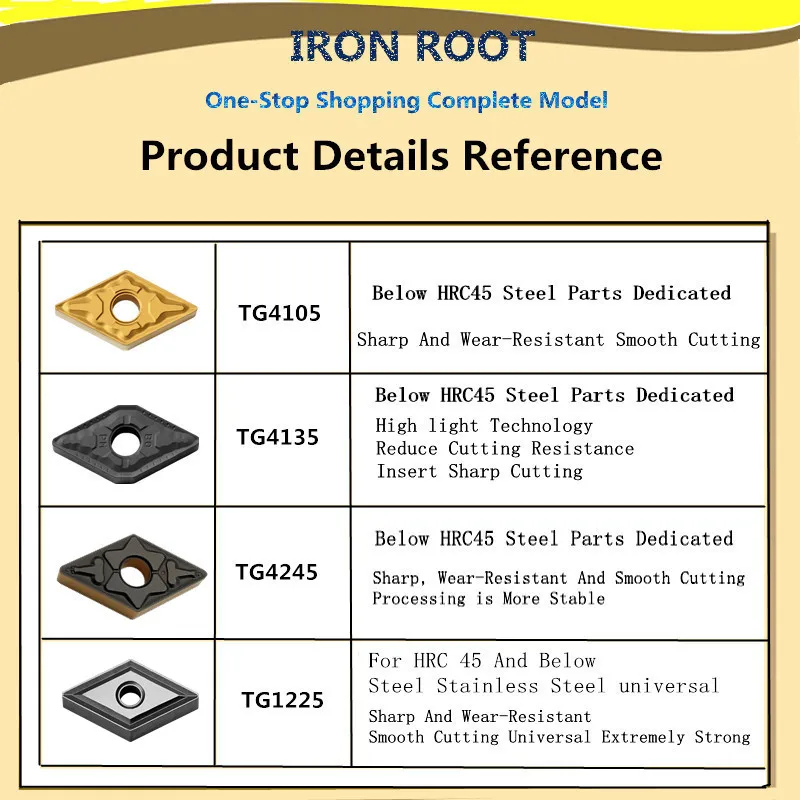

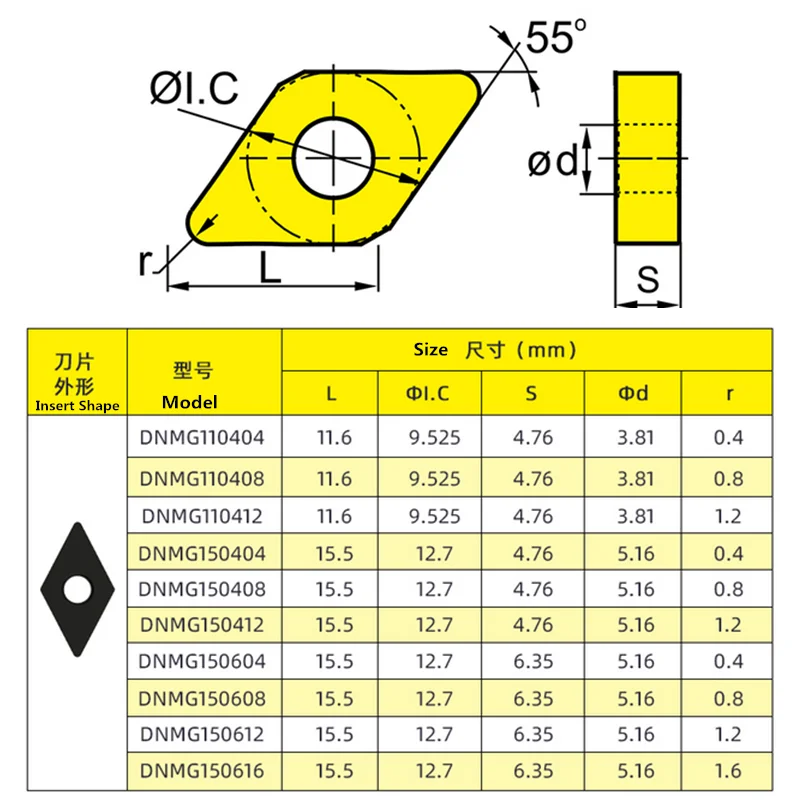

Shape: The insert features a 55° rhombic negative shape. This geometry provides excellent stability during cutting operations, distributing the cutting forces evenly across the insert. The negative rake angle design is particularly effective for machining hard materials like steel and stainless steel, as it enhances the insert's strength and reduces the risk of chipping or breakage.

Dimensions: With a side length of 15.875mm, a thickness of 6.35mm, and a corner radius of 0.4mm, the IRON ROOT DNMG150604 - HM is precisely engineered. The 0.4mm corner radius strikes a balance between sharpness for achieving fine surface finishes in finish - turning operations and durability for heavy - duty roughing, where larger amounts of material need to be removed quickly.

Cutting Edges: It has four effective cutting edges. When one edge becomes dull, the insert can be easily indexed (rotated) to expose a fresh, sharp edge. This indexable feature not only extends the overall lifespan of the insert but also significantly reduces the frequency of tool replacements, leading to increased productivity and cost - savings.

Steel Machining: In the automotive industry, it can be used for machining various steel components such as engine blocks, crankshafts, and transmission gears. For example, when turning the shafts of engines, the IRON ROOT DNMG150604 - HM insert can handle the high - strength steel materials with precision, achieving the tight tolerances required for smooth engine operation.

Stainless Steel Machining: In the food and beverage, pharmaceutical, and aerospace industries, where stainless steel is widely used, this insert proves its worth. It can be used to machine stainless - steel pipes for food processing equipment, components for pharmaceutical machinery, or parts for aircraft engines. The insert's ability to resist the corrosive nature of stainless steel during machining and maintain a sharp cutting edge is highly beneficial. Whether it's rough turning to remove large amounts of stock or finish turning to achieve a mirror - like surface finish, the IRON ROOT DNMG150604 - HM insert is up to the task.