MTR Series Precision Small Hole Boring Tool - 1-10mm Tungsten Steel CNC Processing

Wide range of applications:

Suitable for micro-aperture processing, with a wide range of diameters, which can meet the needs of different aperture sizes, whether it is small precision parts or larger conventional processing, it can easily cope with it.

High processing accuracy:

With micron-level adjustment accuracy, it can achieve high-precision hole processing, ensure the accuracy of the processed hole size, and meet the strict requirements of precision machining.

Good durability:

The blade is made of carbide material, which makes the blade sharp and has sufficient strength, which can effectively reduce cutting stress and extend the service life of the tool.

Easy operation:

The modular interface design is convenient for replacing boring bars or cutter heads of different specifications, and can realize flexible assembly of length and diameter to improve work efficiency.

Good cooling effect:

Some models are designed with internal cooling holes, and the cutting fluid can be directly delivered to the tip of the tool, effectively reducing the cutting temperature, reducing tool wear, and improving processing efficiency and surface quality.

Excellent surface quality:

The grinding-grade chip breaker design can achieve optimal cutting control, make the processed surface smooth, and reduce subsequent processing steps.

A variety of specifications are available:

According to different processing requirements, we provide products of various series and specifications, such as different models in the MTR series, to meet the personalized needs of different customers.

The MTR series of small hole boring cutters are high-quality tools designed for precision machining. They are suitable for processing tiny holes and can meet the needs of different hole sizes. They can easily handle both small precision parts and larger conventional processing. They are exquisitely designed and made of carbide materials, which make the cutting edge sharp and strong enough to effectively reduce cutting stress and extend the service life of the tool. At the same time, the modular interface design makes it easy to replace boring bars or cutter heads of different specifications, and can realize flexible assembly of length and diameter, thereby improving work efficiency.

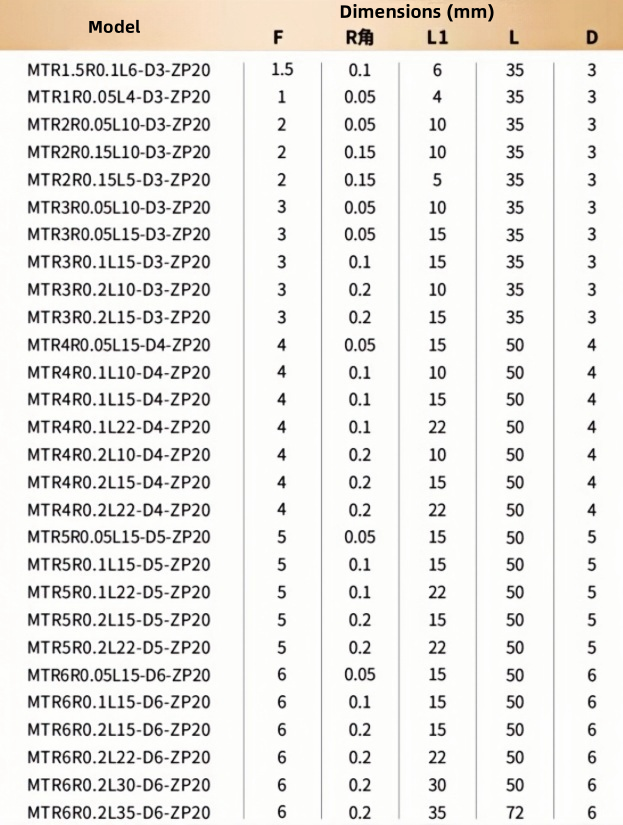

| Model | Dimensions (mm) | ||||

| F | Rhorn | L1 | L | D | |

| MTR1.5R0.1L6-D3-ZP20 | 1.5 | 0.1 | 6 | 35 | 3 |

| MTR1R0.05L4-D3-ZP20 | 1 | 0.05 | 4 | 35 | 3 |

| MTR2R0.05L10-D3-ZP20 | 2 | 0.05 | 10 | 35 | 3 |

| MTR2R0.15L10-D3-ZP20 | 2 | 0.15 | 10 | 35 | 3 |

| MTR2R0.15L5-D3-ZP20 | 2 | 0.15 | 5 | 35 | 3 |

| MTR3R0.05L10-D3-ZP20 | 3 | 0.05 | 10 | 35 | 3 |

| MTR3R0.05L15-D3-ZP20 | 3 | 0.05 | 15 | 35 | 3 |

| MTR3R0.1L15-D3-ZP20 | 3 | 0.1 | 15 | 35 | 3 |

| MTR3R0.2L10-D3-ZP20 | 3 | 0.2 | 10 | 35 | 3 |

| MTR3R0.2L15-D3-ZP20 | 3 | 0.2 | 15 | 35 | 3 |

| MTR4R0.05L15-D4-ZP20 | 4 | 0.05 | 15 | 50 | 4 |

| MTR4R0.1L10-D4-ZP20 | 4 | 0.1 | 10 | 50 | 4 |

| MTR4R0.1L15-D4-ZP20 | 4 | 0.1 | 15 | 50 | 4 |

| MTR4R0.1L22-D4-ZP20 | 4 | 0.1 | 22 | 50 | 4 |

| MTR4R0.2L10-D4-ZP20 | 4 | 0.2 | 10 | 50 | 4 |

| MTR4R0.2L15-D4-ZP20 | 4 | 0.2 | 15 | 50 | 4 |

| MTR4R0.2L22-D4-ZP20 | 4 | 0.2 | 22 | 50 | 4 |

| MTR5R0.05L15-D5-ZP20 | 5 | 0.05 | 15 | 50 | 5 |

| MTR5R0.1L15-D5-ZP20 | 5 | 0.1 | 15 | 50 | 5 |

| MTR5R0.1L22-D5-ZP20 | 5 | 0.1 | 22 | 50 | 5 |

| MTR5R0.2L15-D5-ZP20 | 5 | 0.2 | 15 | 50 | 5 |

| MTR5R0.2L22-D5-ZP20 | 5 | 0.2 | 22 | 50 | 5 |

| MTR6R0.05L15-D6-ZP20 | 6 | 0.05 | 15 | 50 | 6 |

| MTR6R0.1L15-D6-ZP20 | 6 | 0.1 | 15 | 50 | 6 |

| MTR6R0.2L15-D6-ZP20 | 6 | 0.2 | 15 | 50 | 6 |

| MTR6R0.2L22-D6-ZP20 | 6 | 0.2 | 22 | 50 | 6 |

| MTR6R0.2L30-D6-ZP20 | 6 | 0.2 | 30 | 50 | 6 |

| MTR6R0.2L35-D6-ZP20 | 6 | 0.2 | 35 | 72 | 6 |

In terms of machining accuracy, the MTR series of small hole boring cutters has micron-level adjustment accuracy, which can achieve high-precision hole machining, ensure the accuracy of the machined hole size, and meet the strict requirements of precision machining. In addition, some models are designed with internal cooling holes, and the cutting fluid can be directly delivered to the tool tip, effectively reducing the cutting temperature, reducing tool wear, and improving machining efficiency and surface quality. Its grinding-grade chip breaker design can achieve optimal cutting control, make the machined surface smooth, and reduce subsequent machining procedures.

| Name | MTR small bore boring too |

| Material | Tungsten carbide material |

| Hardness | HRC45 degrees |

| Processing conditions | High speed machining/coolant |

| Applicable materials | Stainless steel,die steel,ductile cast iron,alloy steel,tempered steel,etc. |

| Product performance | Sharp and wear-resistant,suitable for both hard and soft surfaces,high finish,surface polishing |

The MTR series of small hole boring cutters also offers a variety of specifications to choose from. According to different machining requirements, such as different diameters, lengths, etc., you can find a suitable model to meet the personalized needs of different customers. In short, the MTR series of small hole boring cutters is an ideal choice for precision machining, and can provide efficient, accurate, and stable performance support for your production and processing.