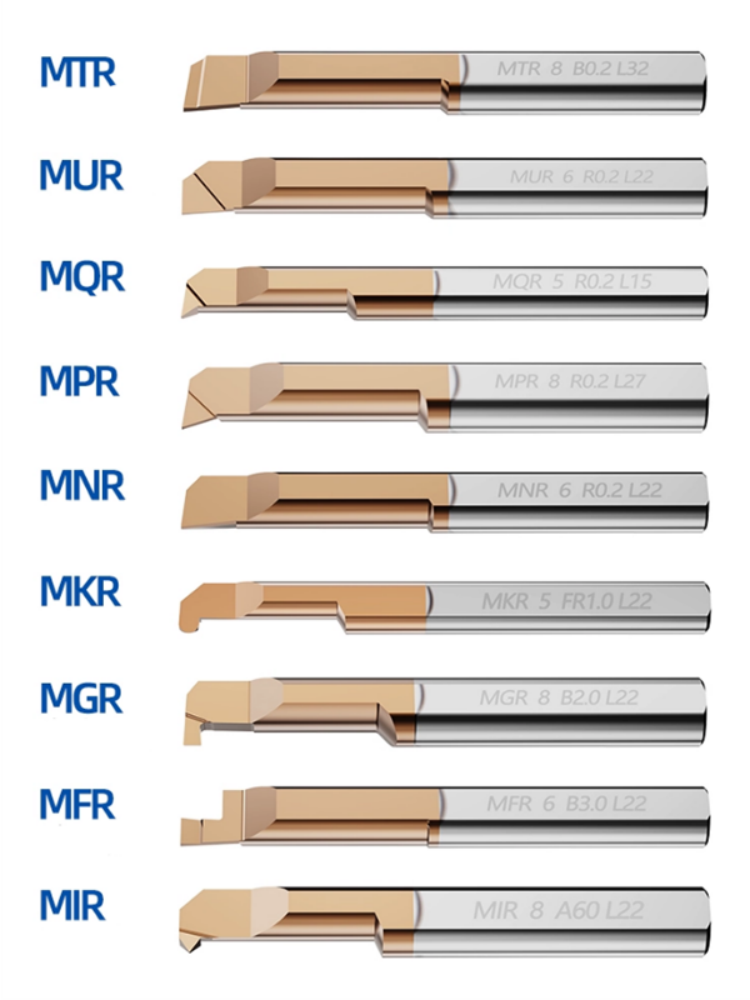

MUR Boring Bar 1.5-8mm, TiAlN Coated Anti-Vibration Tool for CNC Machining

Ultra-micro precision machining capability

Covering ultra-small aperture machining of 1.5-8mm (industry-leading MUR1.5R0.1L6-D4 to MUR8R0.2L27 specifications)2, supporting multi-parameter combinations of blade length 6-27mm, solving the problems of micro-inner holes and thread machining that traditional tools cannot handle16.

High-precision anti-vibration design

Adopting tungsten steel alloy tool body + TiAlN coating technology (hardness up to HRC65+), combined with patented anti-vibration tool bar structure, suppressing vibration amplitude ≤0.005mm, ensuring high finish machining (Ra≤0.4μm) of difficult-to-cut materials such as stainless steel and titanium alloy213.

Intelligent modular configuration

Supports quick replacement of tool heads and tool bars (compatible with MQR/MPR series modules), completes parameter adjustment within 5 seconds, and meets non-standard machining needs such as stepped holes and special-shaped holes412.

The MUR series of small hole boring tools are carbide tools designed for high-precision micro-internal hole processing. With its tungsten steel alloy material and anti-seismic structure design, it performs well in CNC lathes, machining centers and other scenarios. This series takes small-diameter processing as its core advantage, covering a processing range of 1.5mm to 8mm in diameter, suitable for precision cutting of materials such as steel and stainless steel, and is particularly good at high value-added industries such as aerospace and precision instruments16.

Core parameters and specifications

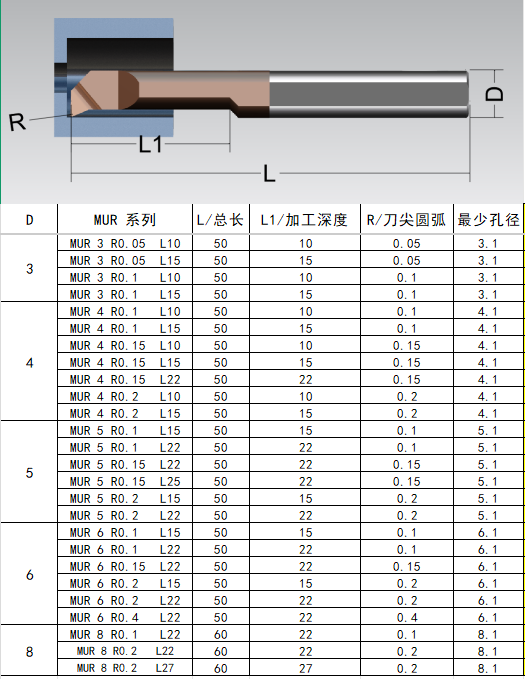

Model system:

The MUR series adopts standardized naming rules. For example, MUR3R0.1L15 means:

Processing diameter 3mm

Tool tip arc radius 0.1mm

Tool bar length 15mm

Other common models include MUR1.5R0.1L6-D4 (shank diameter 4mm), MUR8R0.2L27 (shank diameter 8mm), etc., covering multiple scenarios.

Material and process:

Main material: ultra-fine grain tungsten steel alloy, hardness above HRA92, wear resistance increased by 30%114.

Coating technology: Some high-end models use nano-composite coating (such as TiAlN), high temperature resistance exceeds 1200℃, and tool life is extended6.

Accessory compatibility:

Adapt to various shank diameters such as D3/D4/D6/D8, support mainstream CNC machine tool interface 814

| D | MUR | L | L1 | R | Minimum aperture |

| 3 | D3-MUR 3 R0.05 L10 | 50 | 10 | 0.05 | 3.1 |

| D3-MUR 3 R0.05 L15 | 50 | 15 | 0.05 | 3.1 | |

| D3-MUR 3 R0.1 L10 | 50 | 10 | 0.1 | 3.1 | |

| D3-MUR 3 R0.1 L15 | 50 | 15 | 0.1 | 3.1 | |

| 4 | D4-MUR 4 R0.1 L10 | 50 | 10 | 0.1 | 4.1 |

| D4-MUR 4 R0.1 L15 | 50 | 15 | 0.1 | 4.1 | |

| D4-MUR 4 R0.15 L10 | 50 | 10 | 0.15 | 4.1 | |

| D4-MUR 4 R0.15 L15 | 50 | 15 | 0.15 | 4.1 | |

| D4-MUR 4 R0.15 L22 | 50 | 22 | 0.15 | 4.1 | |

| D4-MUR 4 R0.2 L10 | 50 | 10 | 0.2 | 4.1 | |

| D4-MUR 4 R0.2 L15 | 50 | 15 | 0.2 | 4.1 | |

| 5 | D5-MUR 5 R0.1 L15 | 50 | 15 | 0.1 | 5.1 |

| D5-MUR 5 R0.1 L22 | 50 | 22 | 0.1 | 5.1 | |

| D5-MUR 5 R0.15 L22 | 50 | 22 | 0.15 | 5.1 | |

| D5-MUR 5 R0.15 L25 | 50 | 22 | 0.15 | 5.1 | |

| D5-MUR 5 R0.2 L15 | 50 | 15 | 0.2 | 5.1 | |

| D5-MUR 5 R0.2 L22 | 50 | 22 | 0.2 | 5.1 | |

| 6 | D6-MUR 6 R0.1 L15 | 50 | 15 | 0.1 | 6.1 |

| D6-MUR 6 R0.1 L22 | 50 | 22 | 0.1 | 6.1 | |

| D6-MUR 6 R0.15 L22 | 50 | 22 | 0.15 | 6.1 | |

| D6-MUR 6 R0.2 L15 | 50 | 15 | 0.2 | 6.1 | |

| D6-MUR 6 R0.2 L22 | 50 | 22 | 0.2 | 6.1 | |

| D6-MUR 6 R0.4 L22 | 50 | 22 | 0.4 | 6.1 | |

| 8 | D8-MUR 8 R0.1 L22 | 60 | 22 | 0.1 | 8.1 |

| D8-MUR 8 R0.2 L22 | 60 | 22 | 0.2 | 8.1 | |

| D8-MUR 8 R0.2 L27 | 60 | 27 | 0.2 | 8.1 |

The MUR series of small hole boring cutters have redefined the standard for micro-internal hole processing through material innovation and structural optimization. As China's manufacturing industry transforms towards high-end, this series of products is becoming an indispensable strategic tool in the field of precision processing, providing key technical support for industrial upgrading.