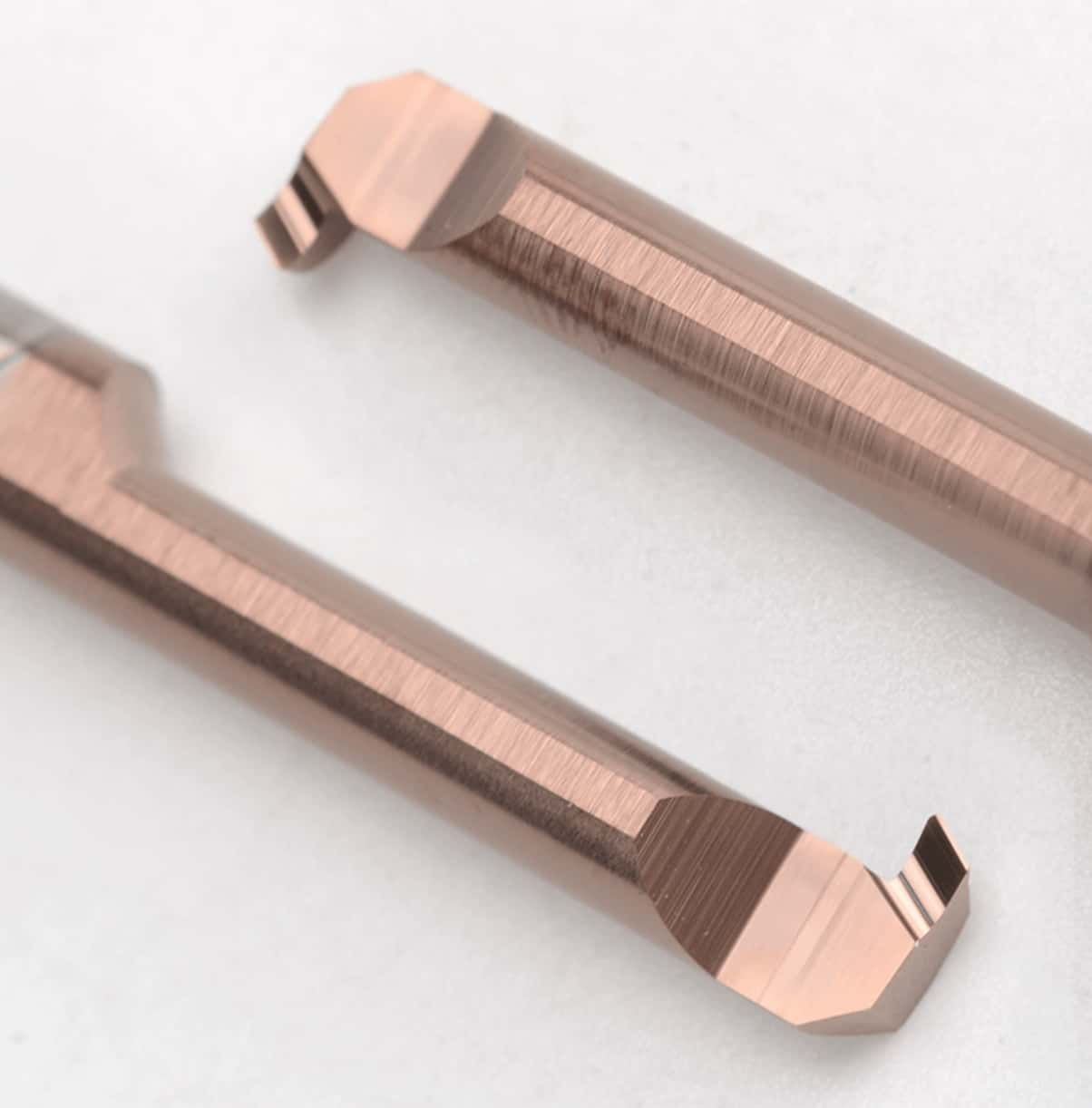

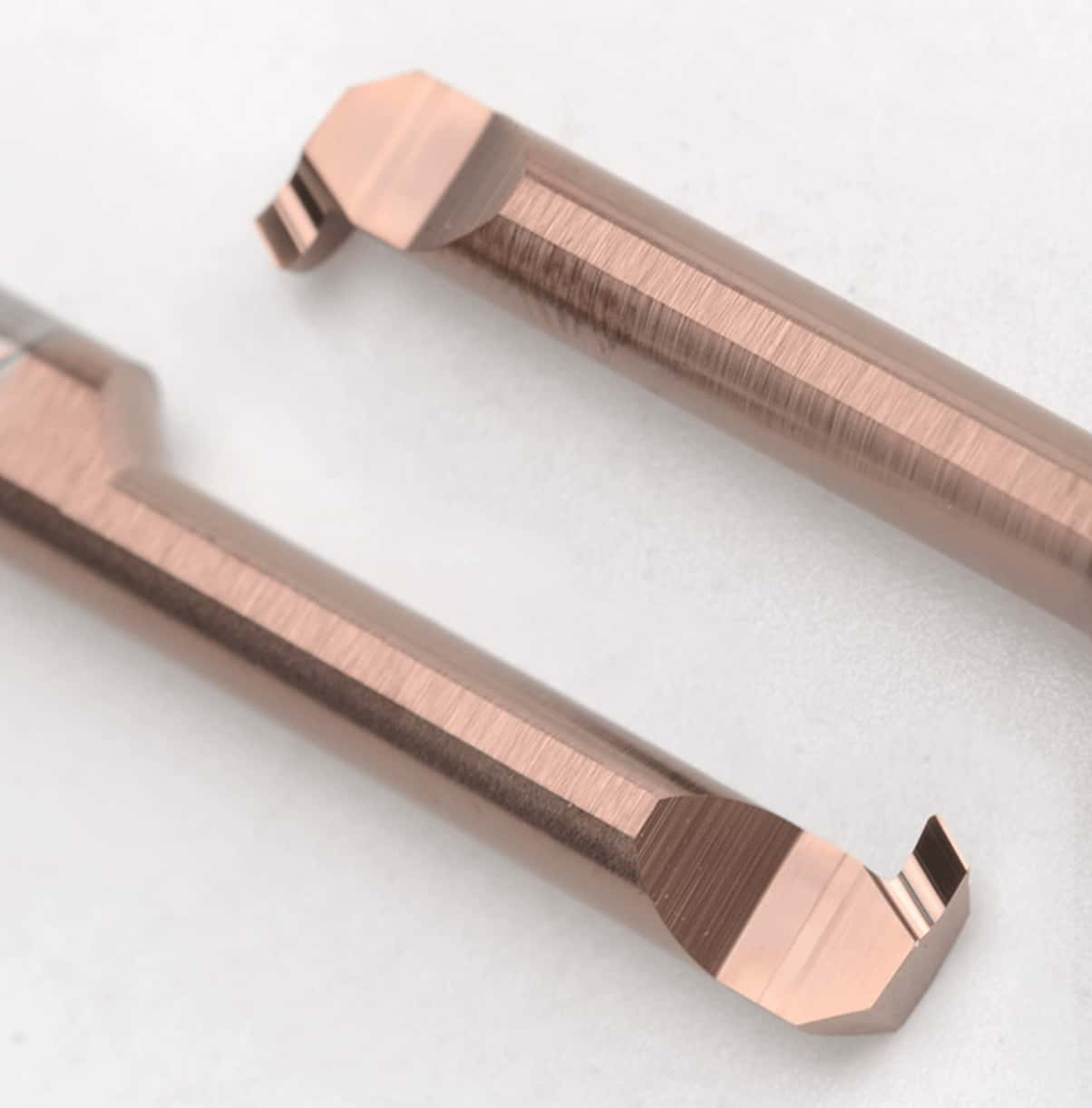

MXR CNC Back Boring Tool Tungsten Carbide Anti-Vibration Bar 45°/60° Shank for Titanium Stainless Steel

Core technology advantages (high precision and durability)

Using tungsten steel alloy and nano-coating technology, the hardness reaches HRC89, and the service life is increased by 300% compared with ordinary tools.

Supports M1-M24 full-specification processing, suitable for high-hardness materials such as stainless steel and titanium alloy.

Innovative structural design

45°/60° shank design: flexibly adapt to turning and milling machine tools, five-axis machining centers and other equipment, covering complex scenes such as deep holes and thin walls.

Reverse boring hook tool technology: optimize the chip discharge path, reduce cutting resistance by 30%, and increase surface roughness to Ra≤0.8μm.

Scenario application advantages (precisely solve industry pain points)

Aerospace field

Applicable to aviation engine parts and high-strength alloy bolt processing, meet AS9100 standards, and achieve ±0.005mm repeat positioning accuracy.

Medical device processing

Designed for micro titanium alloy threads such as bone screws and implants, it complies with ISO 13485 medical certification and avoids the problem of traditional tool chipping.

Multi-industry compatibility

Covering automotive molds, precision instruments and other fields, supporting modular tool head replacement to reduce maintenance costs.

In deep hole processing of aerospace parts, engineers often face the problem of hole diameter deviation caused by tool vibration; in the field of medical devices, the pain point of traditional tools being prone to chipping has long plagued the industry in micro-thread processing of titanium alloy implants. The advent of the MXR small hole boring tool is precisely to solve these high-precision processing challenges. The MXR small hole boring tool adopts a 65° tungsten steel alloy substrate and a nano-scale composite coating process to form a micron-level wear-resistant layer on the surface of the cemented carbide, making its hardness reach HRC89, which is 300% longer than ordinary tool life. The innovative anti-boring hook tool technology reduces processing vibration by 30% by optimizing the cutting force distribution, which is especially suitable for deep hole processing scenarios with a depth-to-diameter ratio greater than 5:1.

Material technology

Tungsten steel alloy + nano coating: hardness reaches HRC89, service life is 300% higher than traditional tools, suitable for high hardness materials such as stainless steel and titanium alloy.

Modular design: The cutter head and tool bar can be quickly disassembled and replaced to reduce maintenance costs.

Specification coverage

Aperture range: supports Φ0.3mm-Φ8mm micro-hole processing, suitable for M1-M24 full specifications.

Handle type selection: provides 45° and 60° two handle angles, matching turning and milling composite machine tools, five-axis machining centers and other equipment.

| D | MXRseries | L | L1 | H/Grooving depth | R | Minimum aperture |

| 4 | D4-MXR 4 B1.0 L10 | 50 | 10 | 1.5 | 0.15 | 4.1 |

| D4-MXR 4 B1.0 L15 | 50 | 15 | 1.5 | 0.15 | 4.1 | |

| 5 | D5-MXR 5 B1.0 L15 | 50 | 15 | 2 | 0.15 | 5.1 |

| D5-MXR 5 B1.0 L22 | 50 | 22 | 2 | 0.15 | 5.1 | |

| D5-MXR 5 B1.5 L15 | 50 | 15 | 2 | 0.15 | 5.1 | |

| D5-MXR 5 B1.5 L22 | 50 | 22 | 2 | 0.15 | 5.1 | |

| 6 | D6-MXR 6 B1.0 L15 | 50 | 15 | 2 | 0.15 | 6.1 |

| D6-MXR 6 B1.0 L22 | 50 | 22 | 2 | 0.15 | 6.1 | |

| D6-MXR 6 B1.5 L15 | 50 | 15 | 2.5 | 0.15 | 6.1 | |

| D6-MXR 6 B1.5 L22 | 50 | 22 | 2.5 | 0.15 | 6.1 | |

| D6-MXR 6 B2.0 L15 | 50 | 15 | 2.5 | 0.2 | 6.1 | |

| D6-MXR 6 B2.0 L22 | 50 | 22 | 2.5 | 0.2 | 6.1 |

Authoritative certification

Passed ISO 9001 quality system certification and complies with AS9100 aerospace standards.

Technical advantages and industry pain point solutions

Ultra-precision machining performance

±0.005mm repeat positioning accuracy: using back-boring hook tool technology to solve the vibration and deflection problems in deep hole processing.

Internal coolant hole design: enhance chip removal efficiency and extend tool life.

Multi-scenario compatibility

Medical devices: Meet the processing requirements of titanium alloy micro holes such as bone screws and implants (in compliance with ISO 13485 standard)58.

Aerospace: Suitable for high-stability processing of engine parts and high-strength alloy bolts210.