DNMG150404-PK TG4245 CNC Carbide Inserts for Steel with High Precision

DNMG150404-PK TG4245 CNC Carbide Inserts for Steel with High Precision

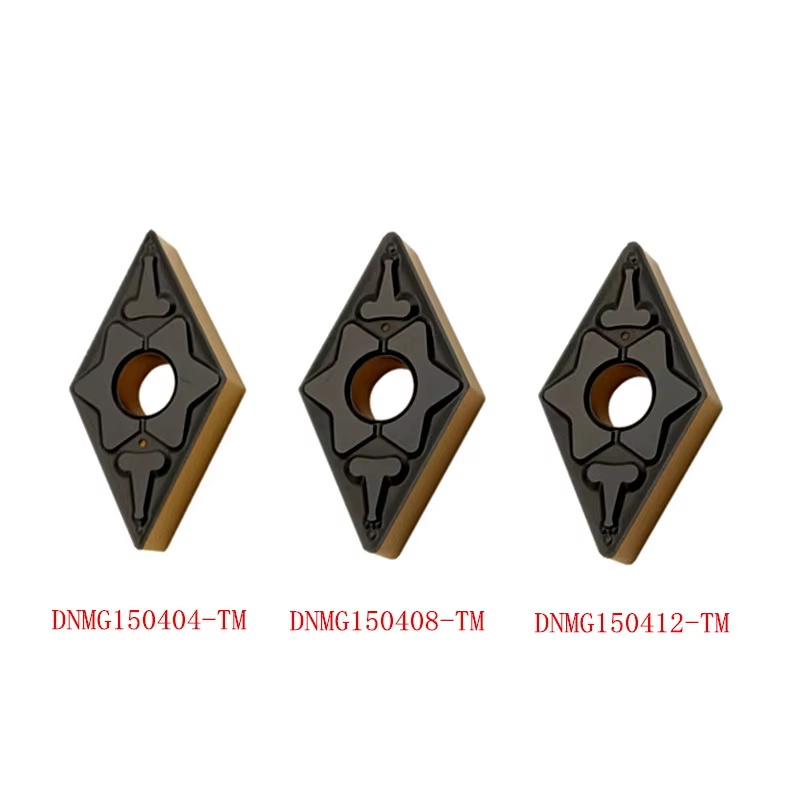

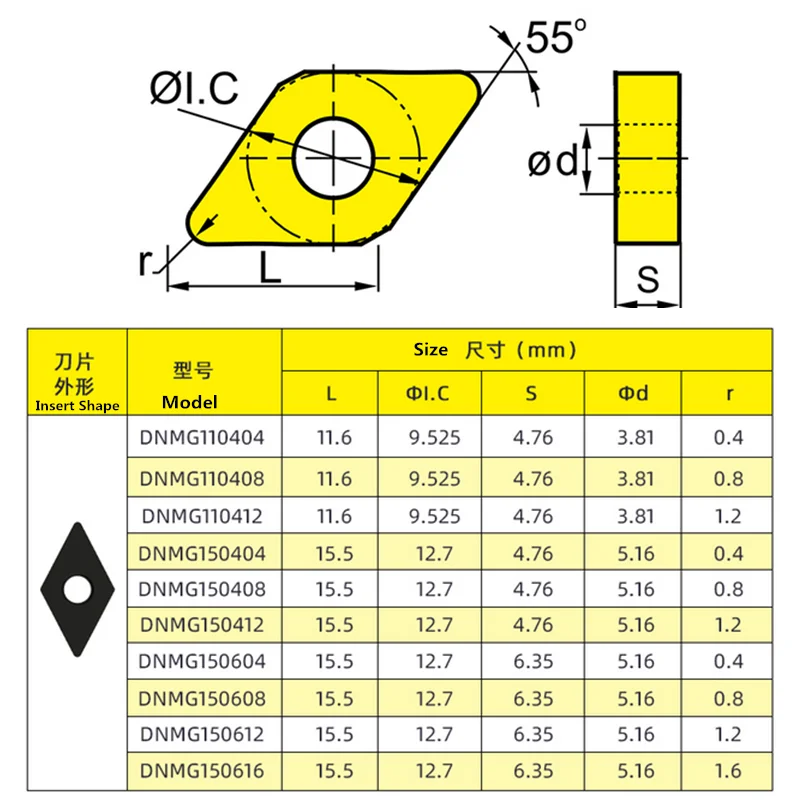

Double-Sided Turning DNMG1504 Rhombus 55 Insert

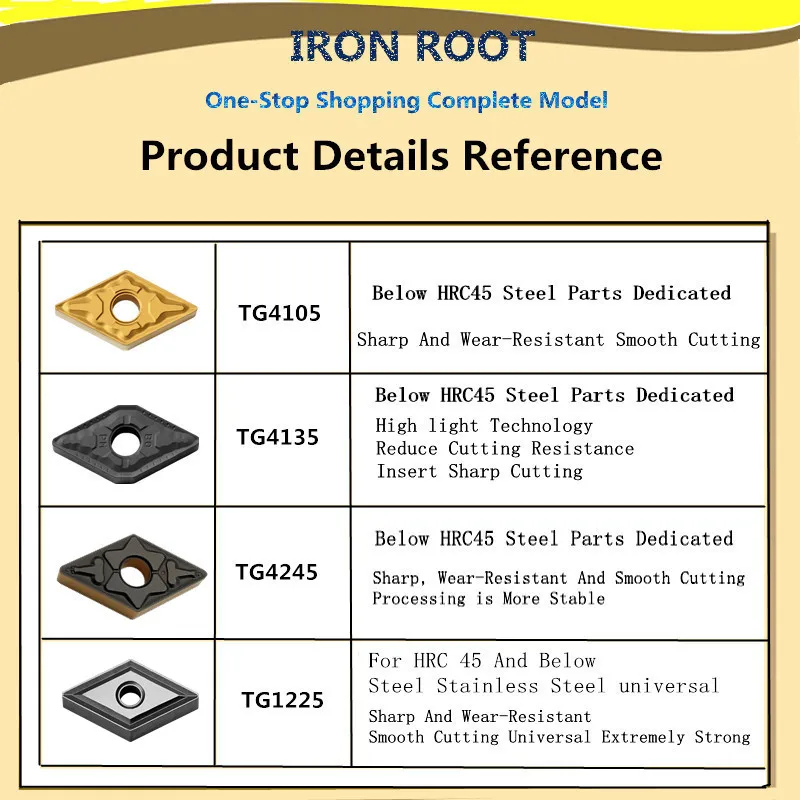

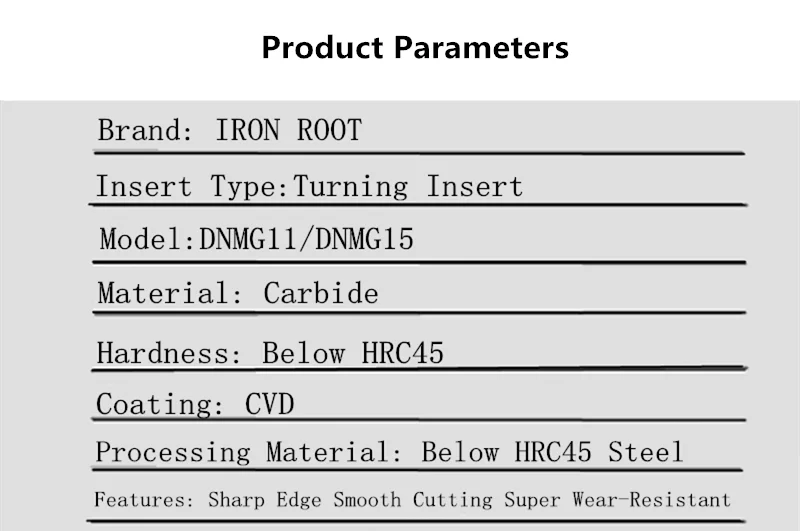

The DNMG150404 - PK TG4245 CNC Carbide Inserts are expertly designed for high - precision steel machining.

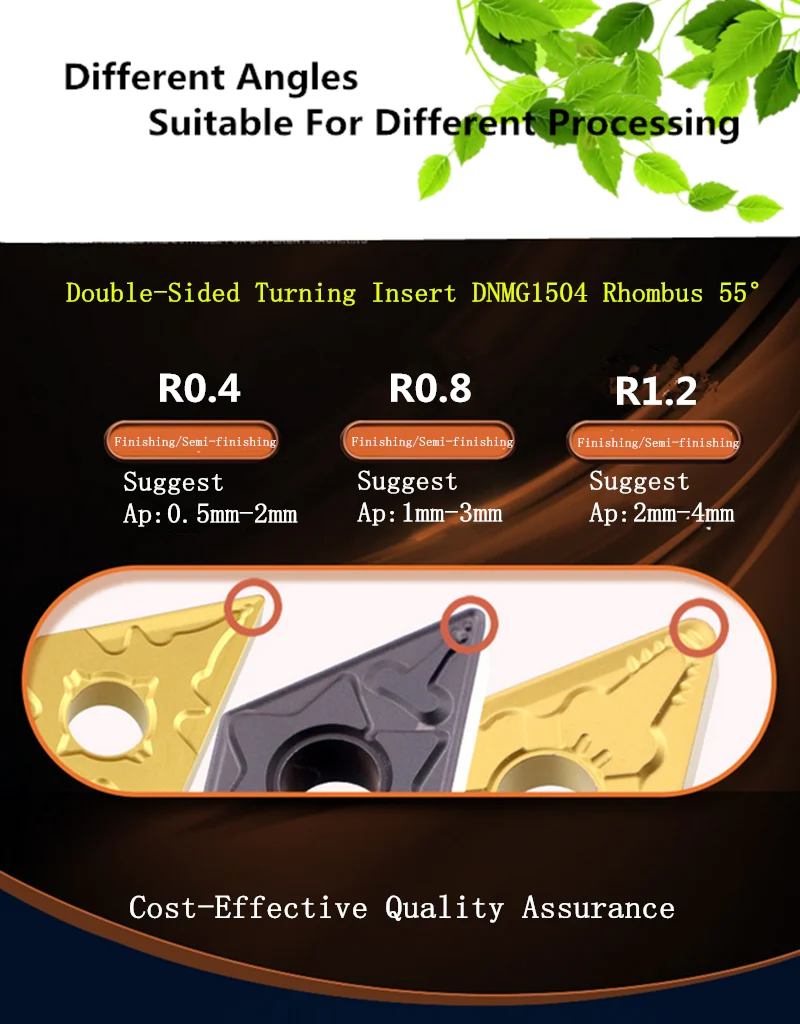

With a 55 - degree rhombus shape and a double - sided structure, these inserts offer remarkable versatility and durability. The "DNMG150404" model indicates specific dimensions: an inscribed circle diameter of approximately 15.875mm, a thickness of 4.76mm, and a tip radius of 0.4mm, ensuring precise cutting in various turning operations.

The PK chipbreaker geometry is a standout feature, optimized to break steel chips efficiently, preventing them from tangling and causing disruptions during machining. This not only enhances the quality of the machined surface but also improves the overall efficiency of the process. Coated with the advanced TG4245 coating, these inserts provide excellent wear resistance, reducing friction and heat generation. The coating's multi - layer structure offers superior adhesion to the carbide substrate, protecting the cutting edges and extending the insert's lifespan.

These inserts are double - sided, allowing users to flip them over and use the other cutting edge once the first side wears out, effectively doubling the tool life and reducing costs. Whether it’s roughing to quickly remove material or finishing for a smooth surface finish, the DNMG150404 - PK TG4245 inserts deliver consistent performance, making them an essential choice for professionals in the automotive, aerospace, and general metalworking industries seeking reliable and high - quality steel machining solutions.