60° high hardness single blade three teeth full teeth, CNC tungsten steel thread milling cutter

High hardness and wear resistance: Made of high-quality tungsten steel (hard alloy), the hardness can reach 45-60HRC, which can easily cut various metal and non-metal materials, and maintain stable performance during long-term processing, with a long service life.

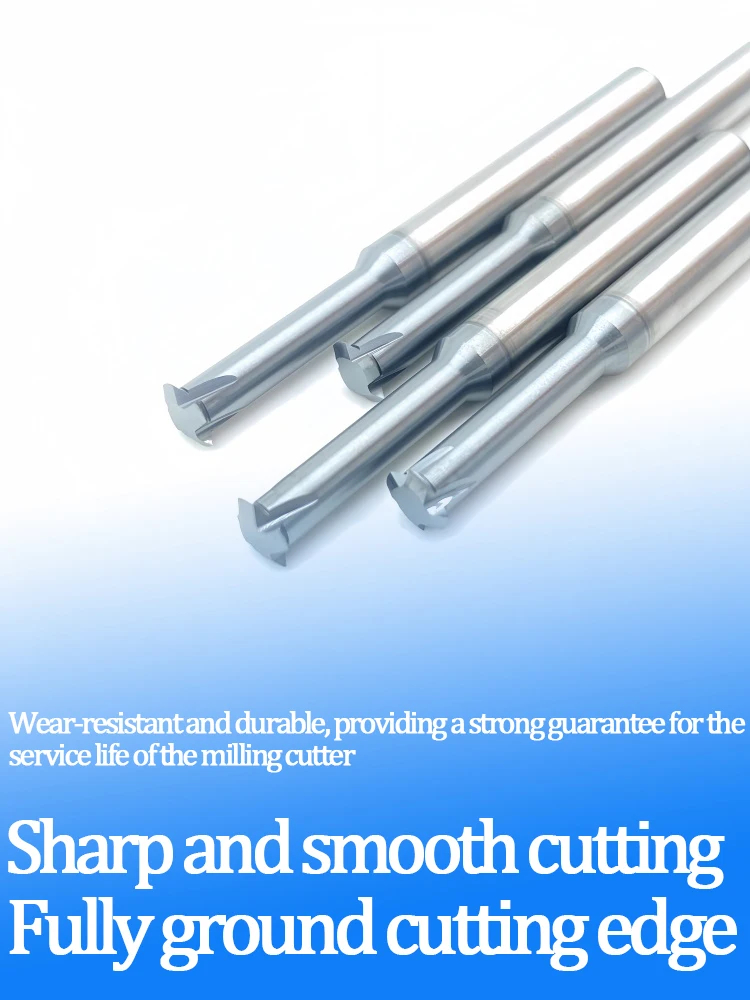

Sharp edge: Advanced mirror grinding technology makes the edge sharper, the cutting force is small, the surface after processing is smooth and delicate, and almost no polishing is required, which saves subsequent processing time. It is especially suitable for workpieces with high requirements for surface finish.

Efficient chip removal: The unique large-capacity chip removal groove design ensures smooth chip removal, avoids tool damage or surface defects caused by poor chip removal, and improves processing efficiency and quality.

Right-hand spiral angle design: The tool adopts a right-hand spiral angle design, which is less likely to break the tip of the tool when cutting, effectively protects the engraving surface, and can also improve the chip removal effect, making the processing process smoother and the operation more efficient.

A variety of shank diameters are available: To meet the needs of different customers, we provide tungsten steel single-edge spiral milling cutters with a variety of shank diameters, such as 3.175mm, 4mm, 5mm, 8mm, etc. Whether it is fine engraving or large-scale relief processing, you can find a suitable model.

Scope of application

The single-tooth thread milling cutter breaks the processing bottleneck of traditional multi-edge tools with its unique single-edge spiral structure. With 0.001mm-level edge grinding accuracy and flexible cutting trajectory control, it is specially designed for high-precision micro threads (such as M1.6×0.35), complex curved threads, and high-hardness aluminum alloy/titanium alloy threads. Its single-edge design can accurately avoid the risk of multi-edge interference, and achieve thread forming accuracy and surface quality that traditional taps and multi-edge milling cutters cannot achieve in scenarios such as aerospace fasteners, medical equipment precision accessories, and 3C electronic micro nuts.