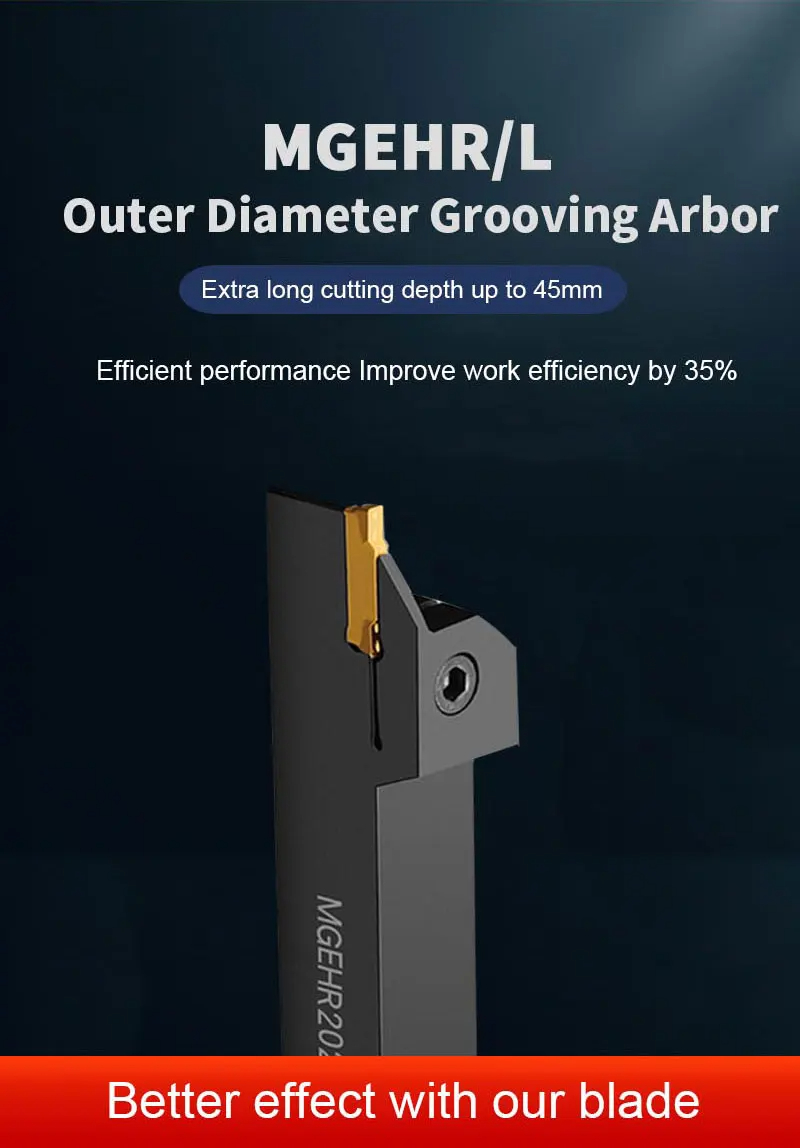

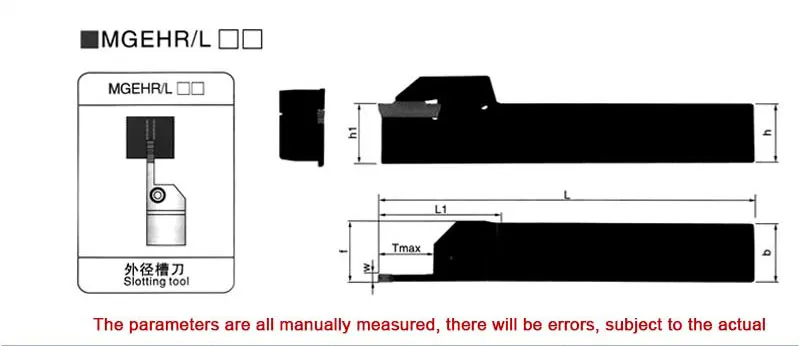

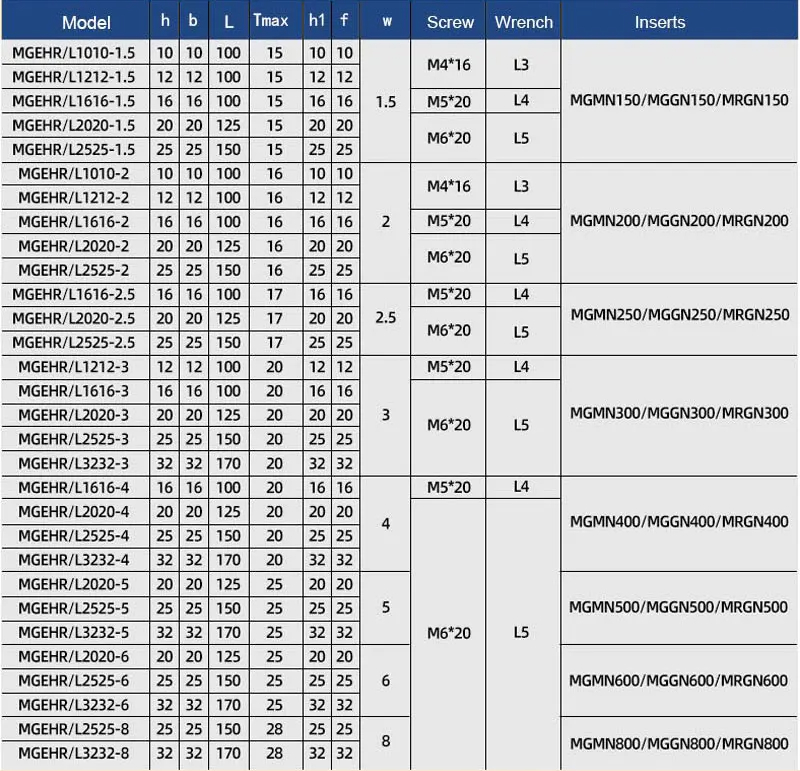

MGEHR/L CNC slotting tool holder for MGMN/MGGN slotting inserts

Excellent material: Spring steel, 40Cr, 42CrMo and other materials are often used. For example, spring steel is shock-resistant and wear-resistant, which can extend the service life of the tool bar and adapt to various lathe processing, including the processing of common steel parts such as stainless steel, aluminum, copper, and castings. 40Cr and 42CrMo are alloy structural steels with high strength. After appropriate heat treatment, they can ensure that the tool bar is not easy to break and deform, and can withstand greater cutting forces.

Exquisite manufacturing technology: The surface of the tool bar is usually polished with imported diamond composites. The surface is delicate and shiny, which is not only beautiful, but also reduces the friction between the chips and the surface of the tool bar, helps chip removal, reduces the possibility of chip adhesion, and improves the quality of the processed surface. At the same time, after high-temperature quenching, tempering and other heat treatment processes,

Clamping is convenient and versatile: screw clamping is adopted, and square head, round head, flat head and bevel head blades can be installed.

High processing accuracy: strict control of manufacturing tolerances, high clamping force, can ensure the position accuracy of the blade during the cutting process, so as to achieve precise grooving, the processed groove width, groove depth and other dimensional accuracy are high, the surface roughness is low, and it can meet higher processing accuracy requirements.

In the field of CNC machining, engineers are always troubled by problems such as unstable grooving accuracy, easy wear and breakage of tool bars, and low tool change efficiency. As a representative of high-performance cutting tools, MGEHR grooving tool bars are designed for high-precision and high-load cutting scenarios with their high-strength materials, precision manufacturing processes, and multi-functional adaptability. MGEHR grooving tool bars are the "golden partner" for CNC lathes, Swiss-type lathes, and other equipment. Its modular design and strict manufacturing standards can not only meet the needs of external cylindrical grooving and cutting processing of various materials such as stainless steel, aluminum, and copper, but also have the characteristics of strong impact resistance, convenient clamping, and long life, making it a key tool for improving efficiency and quality in the machining industry.