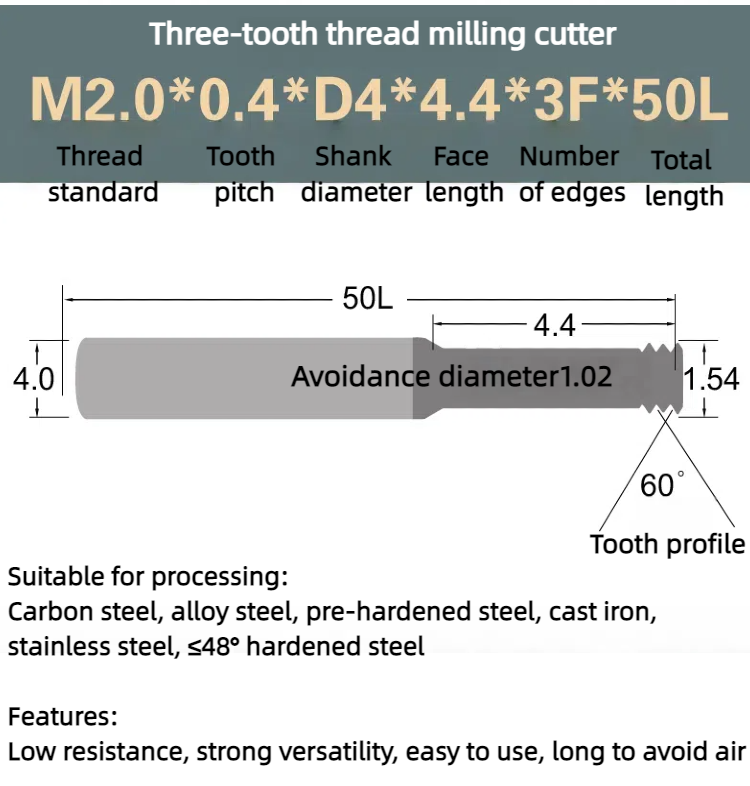

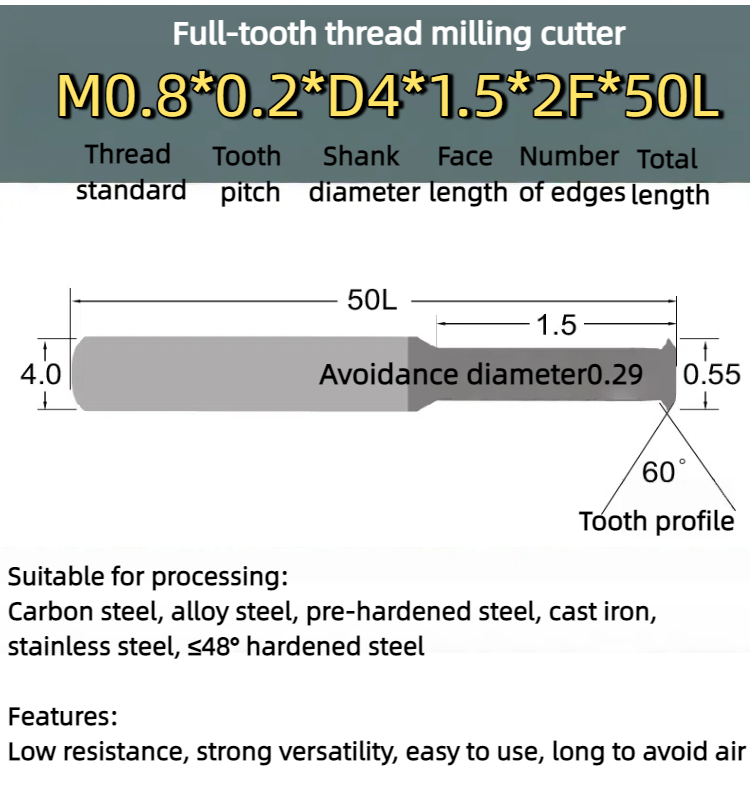

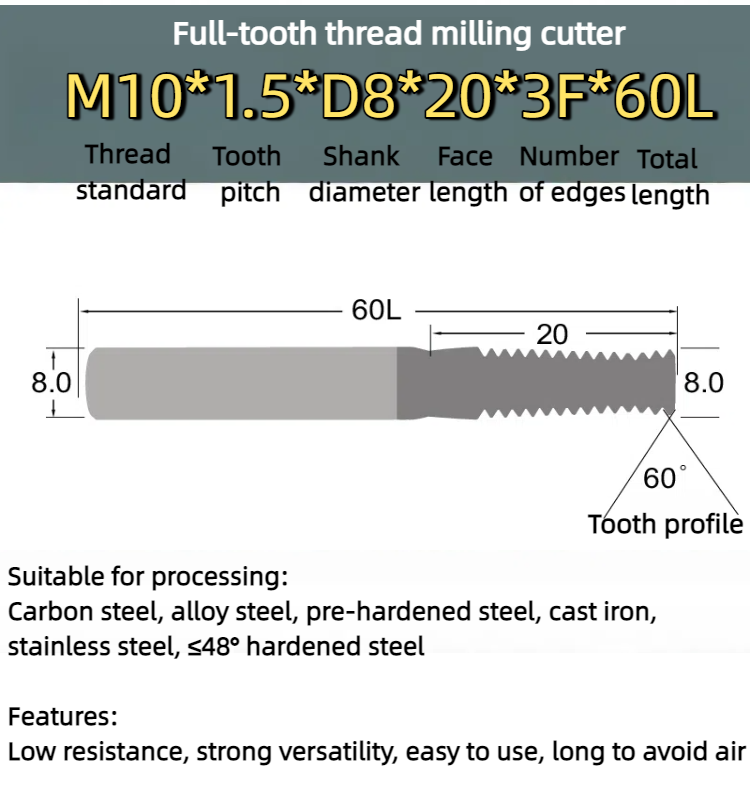

3-edge thread milling cutter, solid carbide TiAlN coating, high precision, suitable for machining steel parts, titanium alloys, etc.

Significantly improved cutting efficiency

Fast feed speed: 30%-50% faster than traditional taps, processing time is shortened by more than 40%, especially suitable for mass production (such as automobile cylinder thread processing).

Deep hole processing capability: With the internal cooling hole design, it can process deep hole threads with a depth ≥5 times the diameter, and the coolant directly reaches the cutting area to improve chip removal efficiency.

Multi-material versatility

Strong universality: compatible with conventional materials such as steel, cast iron, aluminum alloy, copper alloy, etc.

Dry/wet compatibility: coated tools support dry cutting to reduce environmental protection costs; models with cooling holes are suitable for wet cutting to cope with high-load conditions.

Structural design advantages

Three-edge high-efficiency cutting: Compared with single/double-tooth milling cutters, the processing efficiency is increased by 30-50%, suitable for mass production.

Helix angle and chip groove: large helix angle (such as 35°-45°) + large-volume chip groove, chip removal efficiency is increased by 80%, avoiding blockage in deep hole processing.

Anti-vibration short-edge design: cutting edge length ≤ 2 times the diameter, high-speed cutting vibration value <0.02mm/s, no chatter marks on the surface.