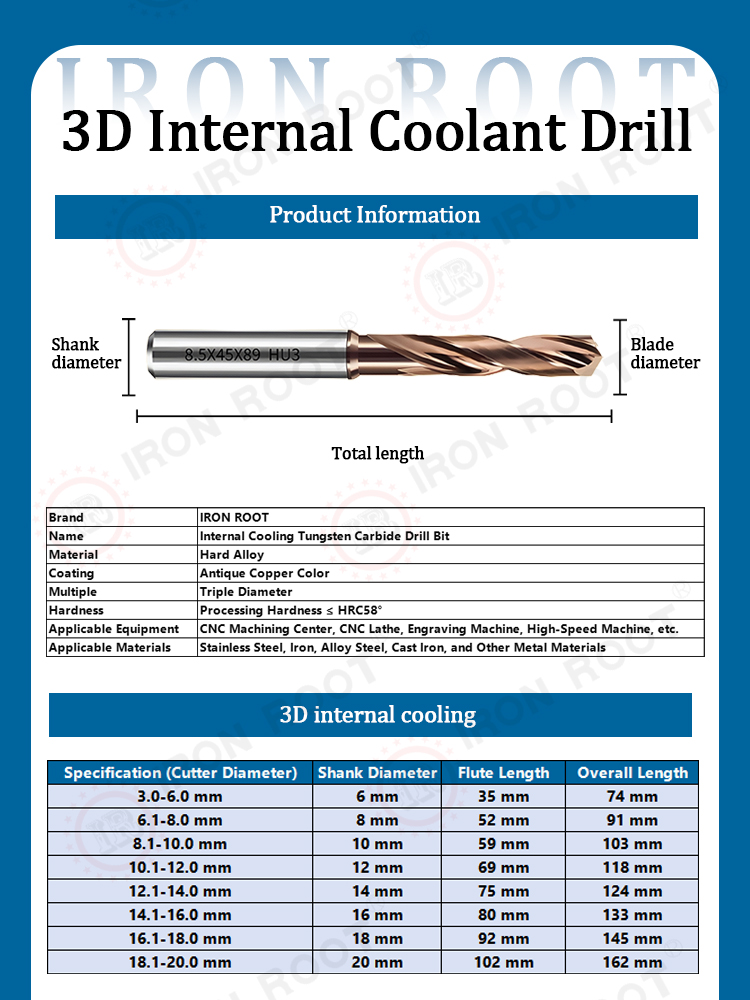

3D Internal Coolant Drill Bit for Metalworking - Tungsten Carbide High Precision CNC Tool for Stainless Steel, Titanium Alloy & Deep Hole Drilling

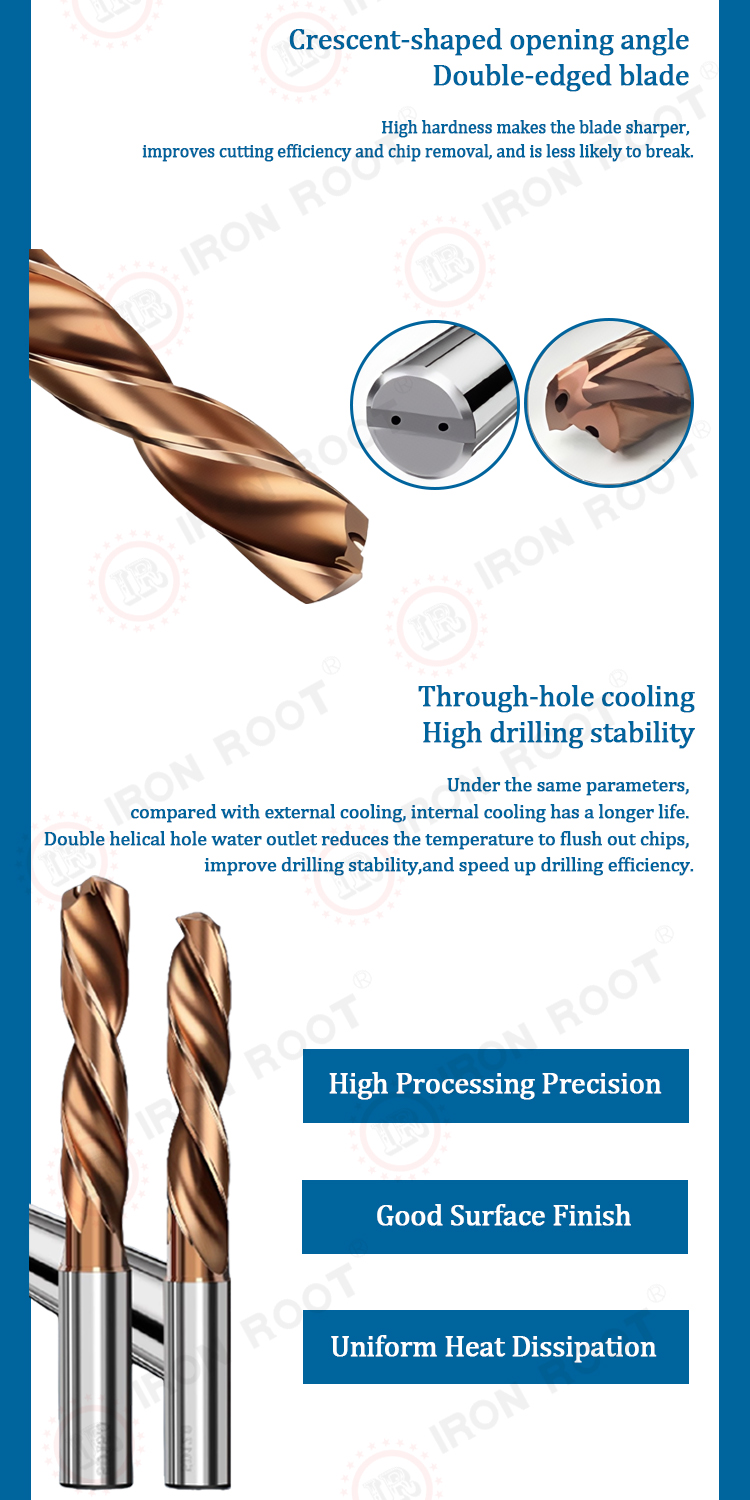

1. Improved cooling performance

Through the spiral or triangular cooling channel (about 1.2mm in diameter) designed inside the drill, the coolant acts directly on the cutting edge, reducing the temperature by more than 50%, effectively avoiding deformation or necrosis of the processed material (such as metal, bone) caused by high temperature310.

Compared with traditional external cooling drills, the coolant flow of 3D internal cooling drills can be increased by 60%-100%, which is especially suitable for deep hole processing (such as tube sheet drilling, orthopedic surgery), reducing the need for midway downtime29.

2. Processing efficiency and precision

Carbide materials (such as tungsten steel) combined with internal cooling allow the speed to be increased by 20%-30%. For example, when processing stainless steel, the cutting speed can reach 80-120m/min712.

Coolant reduces thermal deformation, the aperture error is controlled within ±0.03mm, the straightness is increased by 50%, and the surface roughness Ra≤1.6μm5913.

3. Durability and material adaptability

Ultra-hard physical coatings (such as TiAlN) and corrosion-resistant stainless steel materials (such as 1.4404) increase tool life by 3-5 times, and the number of regrinding times reaches 7-10 times71314.

It can process high-hardness materials such as stainless steel, titanium alloy, and high-temperature alloy, and is even suitable for bone drilling in orthopedic surgery31214.

4. Energy saving and environmental protection

The closed internal circulation design reduces the amount of coolant by about 40% and reduces waste liquid discharge25. After reducing cutting resistance, the energy consumption of machine tools is reduced by 15%-20%29.

5. Advantages in special scenarios

Medical field: Avoid the temperature exceeding the critical value of 50℃ when drilling bones to prevent heat-induced bone necrosis314.

Complex structure processing: 3D printing technology can customize asymmetric cooling channels to meet the needs of special-shaped hole processing1014.