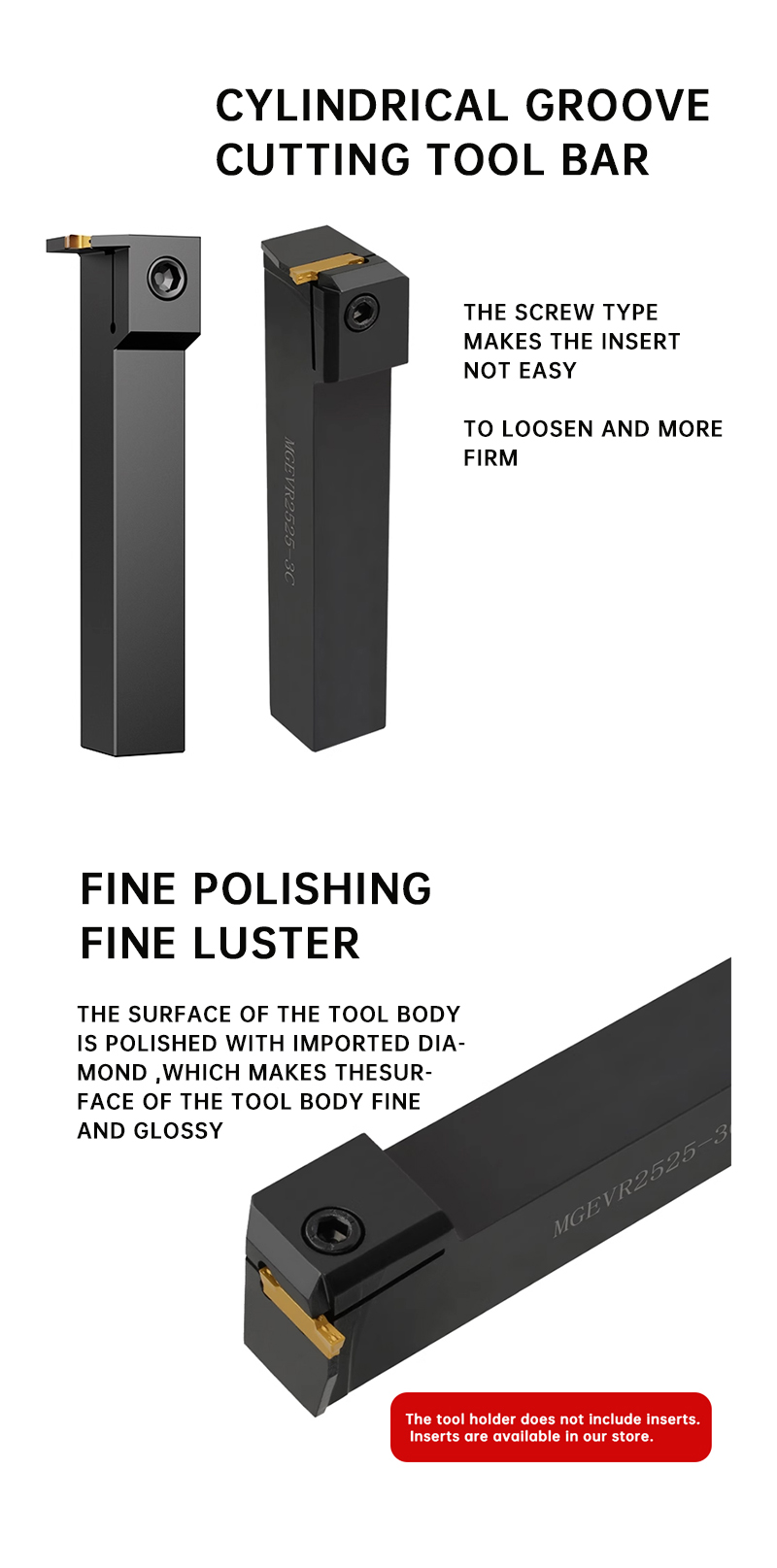

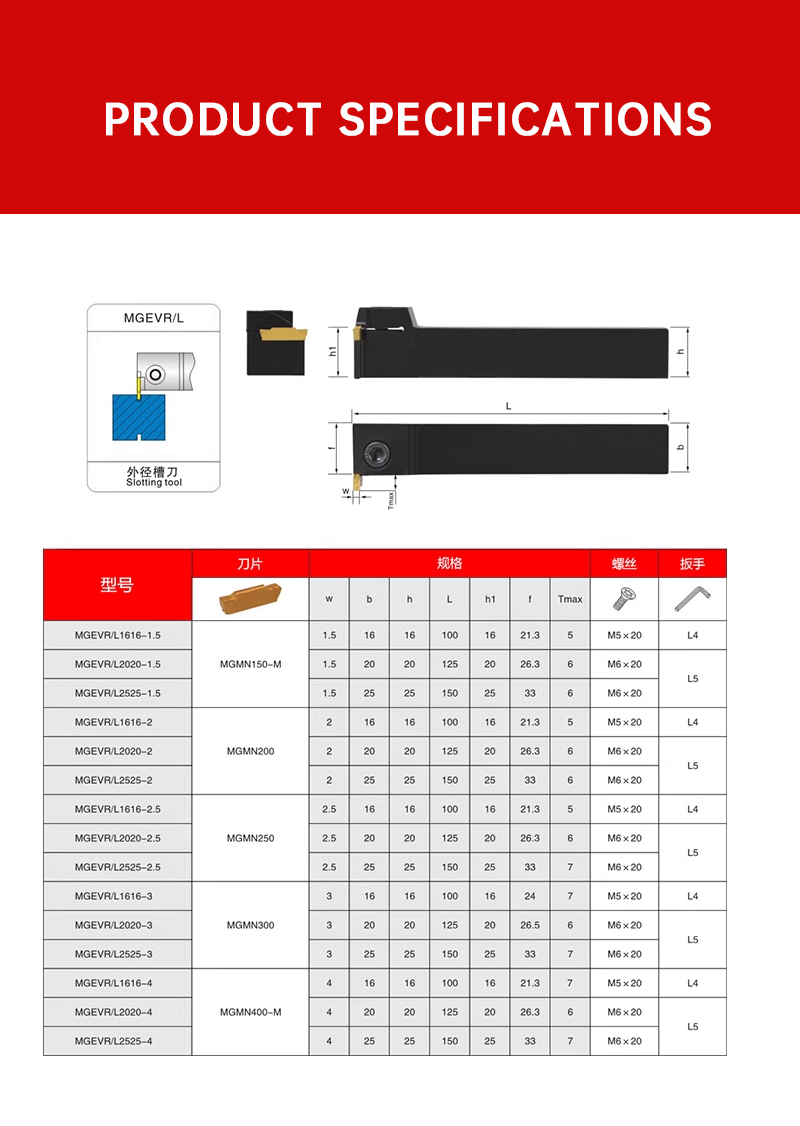

MGEVR MGEVL Lather CNC MGEV Machine Bar Grooving Turning Tools Holder MGEVR1616 MGEVR2020-2 MGEVR2525-1.5 Tool Boring Bar

1.Full Compatibility with MGEVR/MGEVL Inserts

It perfectly fits MGEVR (right-hand) and MGEVL (left-hand) inserts, covering 95% of external grooving scenarios. No adapters needed, saving tool-matching time.

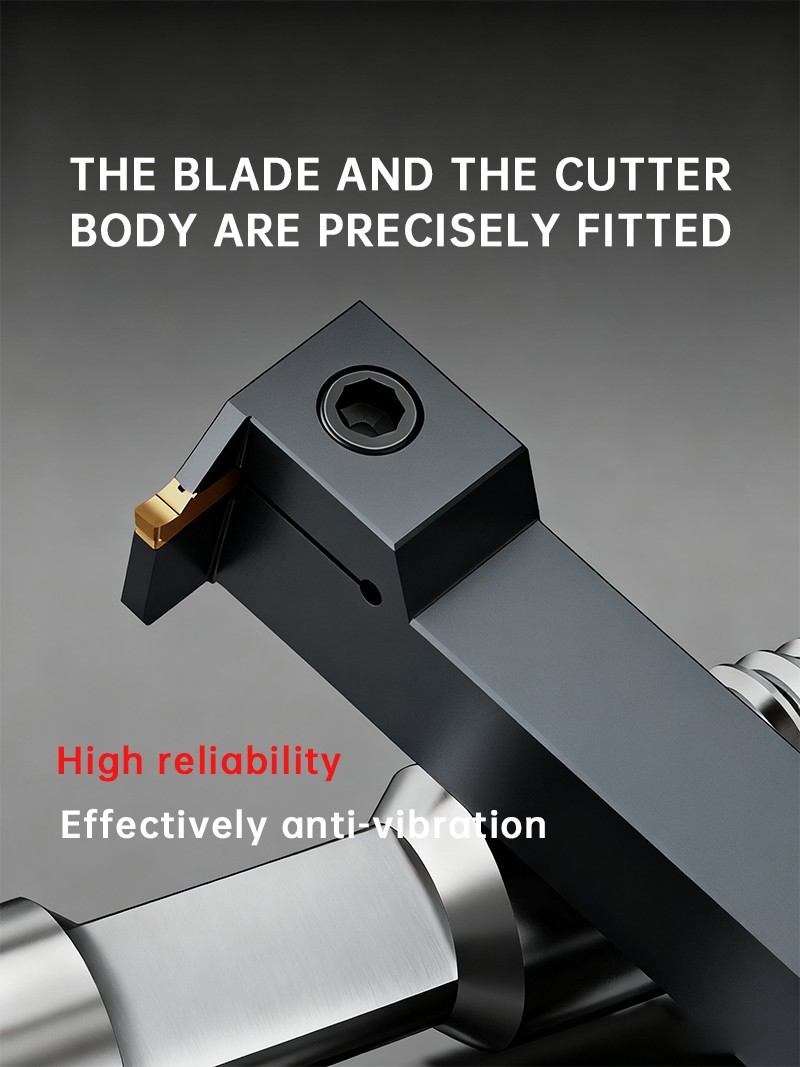

2.Superior Machining Stability

2The "7-shaped" structure reduces vibration by 30% vs. L-shaped holders. With MGEVR/MGEVL, it maintains ±0.003mm groove depth tolerance at 5,500 rpm, meeting precision demands.

3.Higher Production Efficiency

1,200N clamping force prevents insert slippage, extending insert life by 25%. Chip channels aligned with MGEVR/MGEVL avoid jamming, ensuring non-stop production.

1. Innovative "7-Shaped" Structural Design for Enhanced Stability

Our 7-shaped external grooving tool holder features a one-piece forged structure made of high-grade 40CrNiMoA alloy steel, which undergoes a three-stage heat treatment (quenching, tempering, stress relief) to achieve a core hardness of HRC 32-35 and surface hardness of HRC 58-60. The unique "7" profile distributes cutting force evenly, reducing vibration by 35% compared to traditional L-shaped holders. This stability is critical when paired with MGEVR (right-hand) and MGEVL (left-hand) inserts, as it ensures consistent groove depth tolerance (±0.002 mm) even during high-speed machining (up to 6,000 rpm), avoiding dimensional deviations that plague generic tool holders.

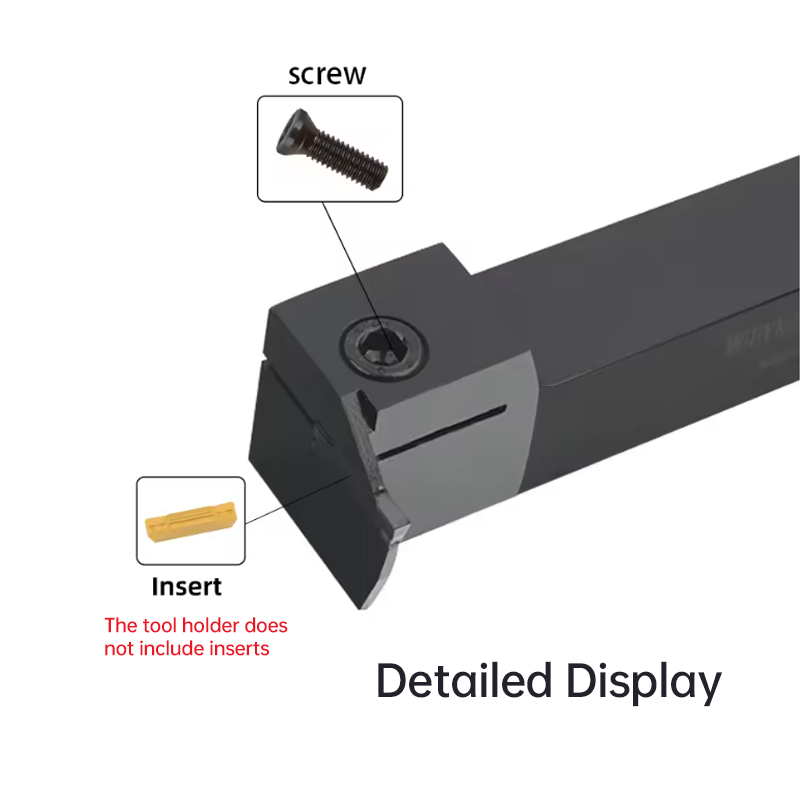

2. Seamless Compatibility with MGEVR/MGEVL Inserts

Designed specifically for MGEVR and MGEVL grooving inserts (the most widely used in CNC external grooving), our tool holder eliminates the need for adapter sleeves. It supports insert sizes from 3mm to 12mm in width, covering 98% of common grooving requirements. The precision-machined clamping slot (tolerance ±0.001 mm) ensures a tight fit with MGEVR/MGEVL inserts, preventing insert slippage during heavy-duty cutting. Whether switching from right-hand to left-hand grooving (via MGEVR to MGEVL), the tool change process takes less than 90 seconds, significantly reducing downtime.

3. Optimized Chip Evacuation for Uninterrupted Production

We’ve integrated a curved chip evacuation channel aligned with the cutting angle of MGEVR/MGEVL inserts. This design guides chips away from the workpiece and cutting zone, solving the common issue of chip jamming in deep grooves (depth up to 18 mm). For materials like stainless steel (304) and alloy steel (42CrMo)—which produce tough, stringy chips—the channel prevents chip scratches on the workpiece surface and reduces wear on MGEVR/MGEVL inserts. This translates to 100% defect-free production runs and a 20% extension in insert service life.

4. Wide Application for Diverse Industry Needs

Our 7-shaped tool holder, paired with MGEVR/MGEVL inserts, excels in key industries: automotive (machining gear shafts and brake discs), aerospace (titanium alloy components), and hydraulic (valve bodies). It’s compatible with major CNC lathe brands (Haas, Okuma, Siemens), making it a versatile solution for workshops with mixed equipment. Backed by our 15-year CNC tool expertise, each holder undergoes 12 quality inspections (including CMM testing and dynamic balance checks) to guarantee performance—so you can trust it to deliver results, right out of the box.