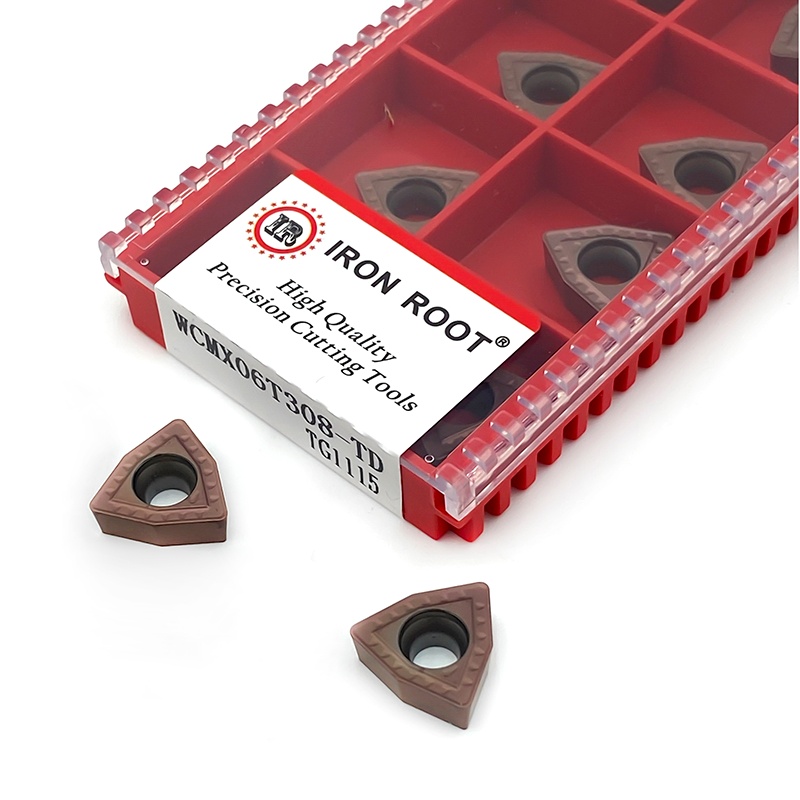

WCMX-TD TG1115 U Drill Insert, High-Precision Stainless Steel Drilling Tool

High-quality materials: Made of high-quality carbide, it has high hardness and good wear resistance, can withstand large cutting forces and high temperature environments, ensure stable performance during processing, and extend the service life of the blade.

Excellent coating technology: Its TG1115-grade coating is specially designed for processing stainless steel, steel and other materials, providing excellent wear resistance and impact resistance, which helps to improve processing efficiency and quality, reduce the frequency of tool replacement, and reduce production costs.

Classic chip breaker design: Makes the blade suitable for finishing and roughing applications, can effectively control the formation and discharge of chips, avoid chip entanglement and blockage, and ensure a smooth processing process.

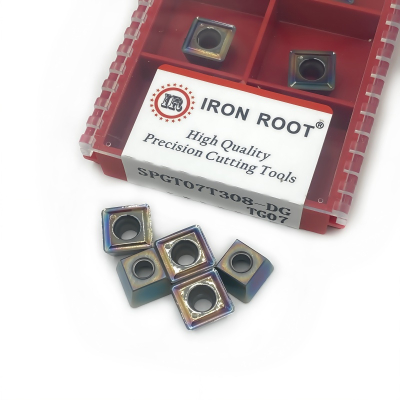

Good versatility: Suitable for a variety of U-drill tool systems, can be used with U-drills of different specifications to meet different processing scenarios and needs, and provide users with flexible processing solutions.

High-precision processing: Suitable for high-precision drilling of stainless steel and steel materials, widely used in automobiles, aerospace, machinery manufacturing and other industries.

Durability: The internal cooling structure extends the service life of the blade and improves processing efficiency.

Economic efficiency: The indexable blade design only requires the replacement of the blade instead of the entire tool when worn, saving costs.

WCMX-TD TG1115 U drill blade is a high-quality cutting tool designed for high-precision drilling of stainless steel, steel and other materials. The blade is made of high-quality cemented carbide, has high hardness and excellent wear resistance, can withstand large cutting forces and high temperature environments, ensure long-term stable processing performance, and significantly extend the service life of the blade.

Its TG1115-grade coating is specially designed for the processing of stainless steel, steel and other materials, which can effectively improve the wear resistance and impact resistance, thereby achieving higher processing efficiency and quality, reducing the frequency of tool replacement, and helping users reduce production costs. The classic chip breaker design makes the blade suitable for fine processing and rough processing, which can effectively control chip formation and discharge, avoid chip entanglement and blockage, and ensure a smooth processing process.

In addition, the blade has good versatility and is suitable for a variety of U drill tool systems. It can be used with U drills of different specifications to meet various processing needs. It is widely used in industries such as automobiles, aerospace, and machinery manufacturing, and is an ideal choice for high-precision drilling of stainless steel and steel materials.

Product Advantages

High-quality materials: Made of high-quality carbide, ensuring high hardness and good wear resistance.

Excellent coating technology: TG1115-grade coating provides excellent wear resistance and impact resistance.

Classic chip breaker design: Suitable for finishing and roughing, effectively controlling chip formation and discharge.

Good versatility: Suitable for a variety of U-drill tool systems to meet the needs of different processing scenarios.

High-precision processing: Suitable for high-precision drilling of stainless steel and steel materials.

Durability: The internal cooling structure extends the service life of the blade and improves processing efficiency.

Economical: The indexable blade design only requires the blade to be replaced instead of the entire tool when worn, saving costs.

Application areas

Automobile manufacturing: high-precision drilling of engine blocks, gearbox housings, brake components, etc.

Aerospace: precision machining of structural parts, landing gear parts, etc.

Machinery manufacturing: efficient drilling of frames, molds, dies, etc.

Oil and gas: machining of drill bits, valves, flanges, etc.

| Product Brand | IRON ROOT |

| model | WCMX |

| Brand | TG1115 |

| Applicable | Finishing and roughing |

| Processing | Stainless steel, steel and other materials |

| Material | Cemented Carbide |