MGGN Carbide Grooving Inserts

About the product

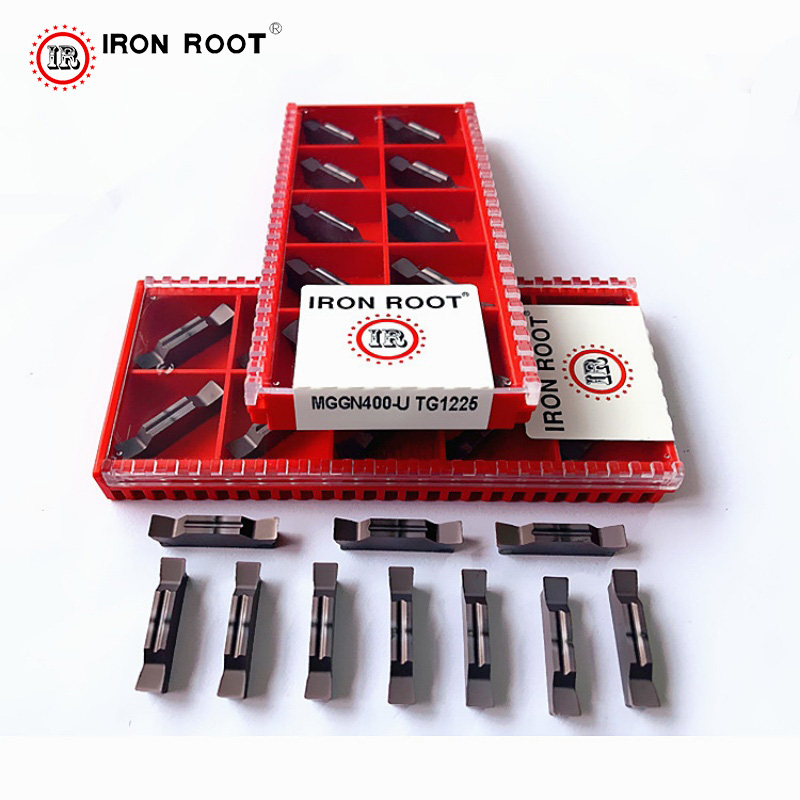

1. Material:MGGN grooving inserts are crafted with carbide, ensuring high durability and precision in machining.

2. Insert Application:Our carbide grooving inserts are equipped with advanced CVD and PVD coatings, enabling them to process a wide range of workpiece materials, including steel, stainless steel, cast iron, and more.

3.Feature of Cutting Holder:Holders are made from strong 40Cr steel, marked with laser lettering for easy identification and protected with anti-rust oil.

4.Package:MGGN grooving inserts come in plastic boxes, simplifying storage .

Material & Coating

MGGN grooving inserts are precision-crafted from high-grade carbide, featuring a fine-grained tungsten carbide substrate with a cobalt binder (6–8% content) to balance hardness (91–92 HRA) and impact resistance. They are enhanced with advanced CVD (Chemical Vapor Deposition) and PVD (Physical Vapor Deposition) coatings, which provide exceptional wear resistance, oxidation resistance up to 1,000°C, and reduced friction. This coating combination extends edge life and ensures stable performance across diverse machining conditions.

Key Features

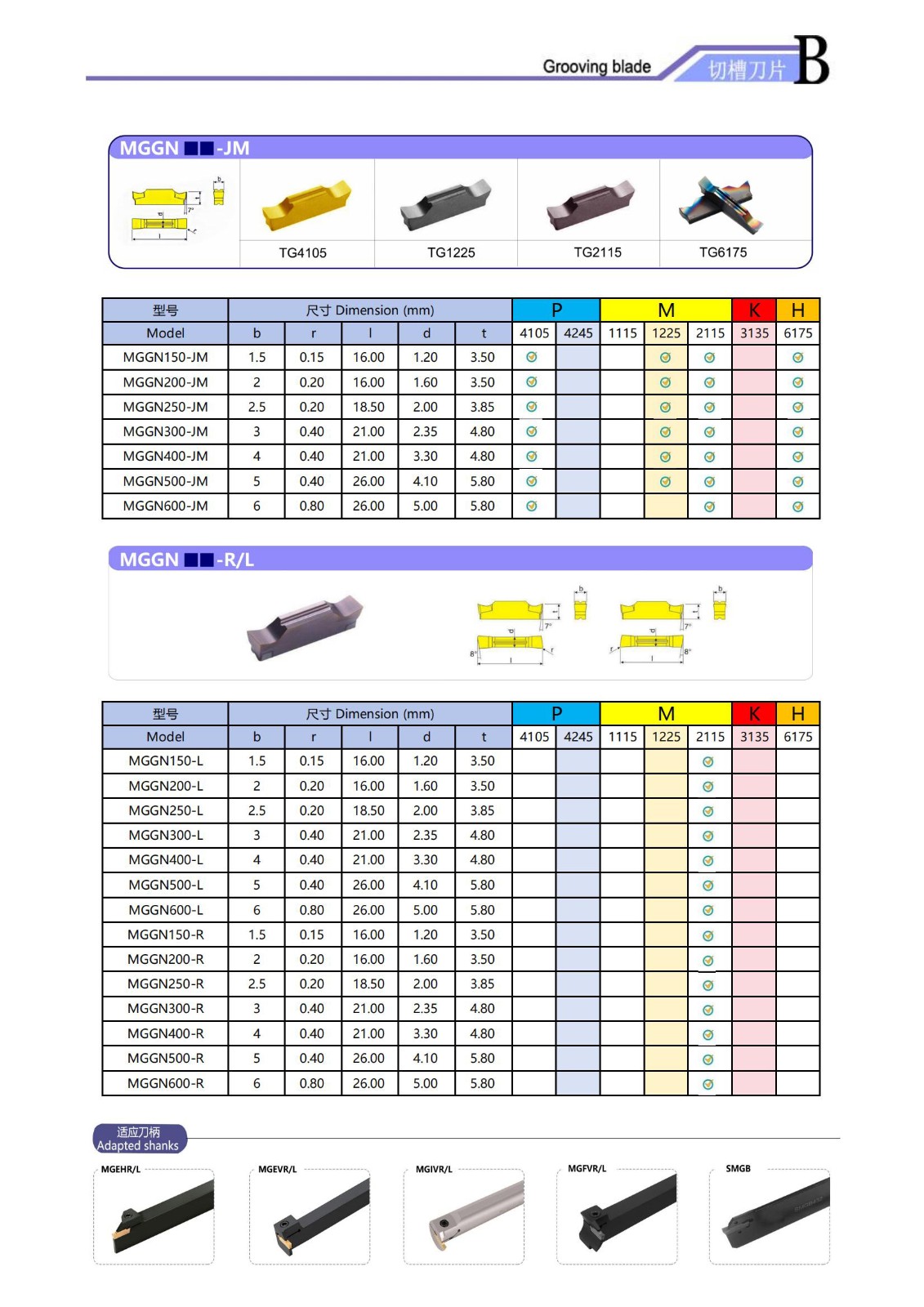

Broad Compatibility: Designed to seamlessly fit popular toolholders, including MGEHR/L, MGEVR/L, MGIVR/L, MGFVR/L, and SMGB series, maximizing flexibility in tool setups.

Versatile Sizing: Available with cutting edge widths ranging from 1.5mm to 6.0mm, catering to a wide spectrum of grooving depths and widths for varied applications.

Dual Groove Types: Offered in JM and R/L groove configurations—JM for general-purpose grooving and R/L for enhanced chip control in specific materials—optimizing performance for different cutting needs.

Durable Toolholder Design: Paired toolholders are constructed from robust 40Cr steel, featuring laser-etched markings for quick identification and anti-rust oil protection to prevent corrosion in workshop environments.

Reliable Quality & Stock: Ensures consistent precision and availability with sufficient inventory, minimizing production downtime.

Applications

Ideal for grooving operations across multiple materials, including:

Steel & Alloy Steel: Machining oil grooves, snap ring grooves, and retaining grooves in automotive shafts, gears, and structural components.

Stainless Steel: Creating precision grooves in food processing equipment, medical tools, and chemical industry parts.

Cast Iron: Forming slots and grooves in engine blocks, pump housings, and industrial machinery components.

MGGN Carbide Grooving Inserts Models | ||

JM groove type | L groove type | R groove type |

MGGN150-JM | MGGN150-L | MGGN150-R |

MGGN200-JM | MGGN200-L | MGGN200-R |

MGGN250-JM | MGGN250-L | MGGN250-R |

MGGN300-JM | MGGN300-L | MGGN300-R |

MGGN400-JM | MGGN400-L | MGGN400-R |

MGGN500-JM | MGGN500-L | MGGN500-R |

MGGN600-JM | MGGN600-L | MGGN600-R |

Compatible Machines

MGGN inserts are optimized for use with:

CNC lathes (e.g., Fanuc, Siemens, and Haas models) equipped with compatible MGEHR/L, MGEVR/L, and other specified toolholders.

Manual lathes with grooving attachments, supporting both internal and external grooving tasks.

Lifespan

Carbide Grooving Inserts CNC turning cutting tools Under recommended parameters (cutting speed: 100–200 m/min; feed rate: 0.05–0.15 mm/rev), the carbide construction and coated surfaces extend insert life:

40–60 minutes of continuous grooving per edge on steel.

30–45 minutes per edge on harder materials like stainless steel or cast iron.

The wear-resistant design reduces edge chipping, ensuring consistent performance across multiple uses before replacement.

Additional Details

Packaging: Supplied in sturdy plastic boxes for organized storage and protection against damage during handling.

Toolholder Durability: 40Cr steel toolholders, with proper maintenance (regular cleaning and lubrication), maintain structural integrity for 8,000+ hours of operation.

Ordering Information:

MGGN Grooving Inserts For accurate pricing and delivery details for our MGGN Carbide Grooving Inserts , please reach out to our sales team. We also provide tailored solutions to fit your unique project needs. Let us help you find the perfect match for your requirements.

About Our Company

Jinan Xinxin Trading Co., Ltd. is a company specializing in a full range of turning tools, milling tools, holemaking tools, carbide cutting tools, machine tool accessories and

other products. At the same time, we accept non-standard product customization and provide perfect tooling solutions for the machining and manufacturing industry.

After years of development, our company firmly believe in the concept of integrity-based, with high-quality service so that the company's products are exported to

Europe, the Middle East, South America, Southeast Asia throughout the world's more than 40 industrialized countries and regions, won the majority of domestic

and foreign customers to support and trust.

Jinan Xinxin Trading Co., Ltd. was founded in 2012, is an excellent comprehensive imported CNC cutting tools agents in Shandong, the company firmly believe in

the concept of good faith, with high quality and attentive service. The company believes in the concept of good faith, with high quality and attentive service. For

the various machining enterprises to supply the world's famous brands of imported CNC cutting tools, machining center tools.

Company Brands

Our company brand IRONROOT series products, with excellent quality and perfect service, strive to reduce the cost of using tools for you.

Main products

Our company, as an important link in the machining field, is following and driving its whole system to run. Our distribution of products has become increasingly systematized, mainly including: Sandvik Coromant sandvikcoromant, Seco, Walter, Kennametal Group Kennametal, Mitsubishi MITSUBISHI, Sumitomo Sumitomo, Kyocera Sholette Kyocera CERATIP, Toshiba, Daijie, Hitachi Tools HITACHI TOOL, ISCAR ISCAR, German cobalt collar Guehring, TEGUTEC TAEGUTEC, KORLOY KORLOY and so on.

Domestic brands: Zhuzhou Diamond Brand, Zigong Great Wall Brand, Zhuzhou Jingcheng Brand, Chengdu Yingge, Ha Yigong, Harbin Tool Factory, Southwest Tools, Chengqi Tools, Shaanxi Cemented Carbide, Zhuzhou Cemented Carbide, Guizhou Yihai, Shanghai Tool Factory and a series of domestic and foreign well-known brands of manufacturers of various types and specifications of CNC blades, Metal lathe tools CNC cutting tools, whole tools, machine-clamped blades, welded blades, toolposts, shank, holder, tungsten steel slats, bars. Tungsten steel slats and bars.

At present, our company's product range includes turning tools, milling tools, drilling tools, tooling systems, carbide cutting tools, machine tool accessories and so on.

Our Customer Reviews

Our products are exported to various countries,milling insert including the United States, the United Kingdom, Spain, Italy, Belgium, France, Germany, etc., and are deeply loved and supported by users in these countries.

Thank you very much for watching

Welcome to inquire about the prices, and we will provide you with the best service.

Website: https://www.ironrootcnctools.

Whatsapp/Mobile: +86 13969129141

Email: lronroot190@gmail.com