Straight-Shank Chamfer Cutter 6.3-60 mm 1-Flute & 3-Flute Countersink Drill Bit

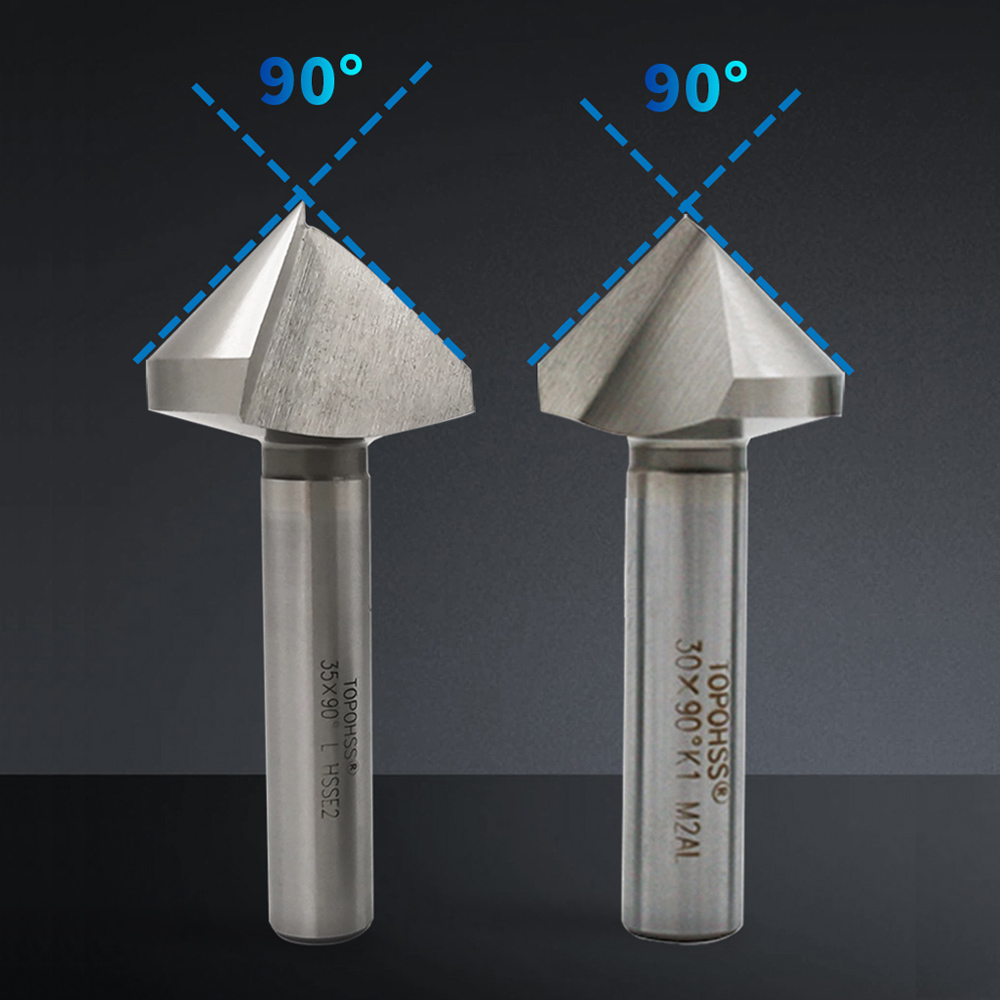

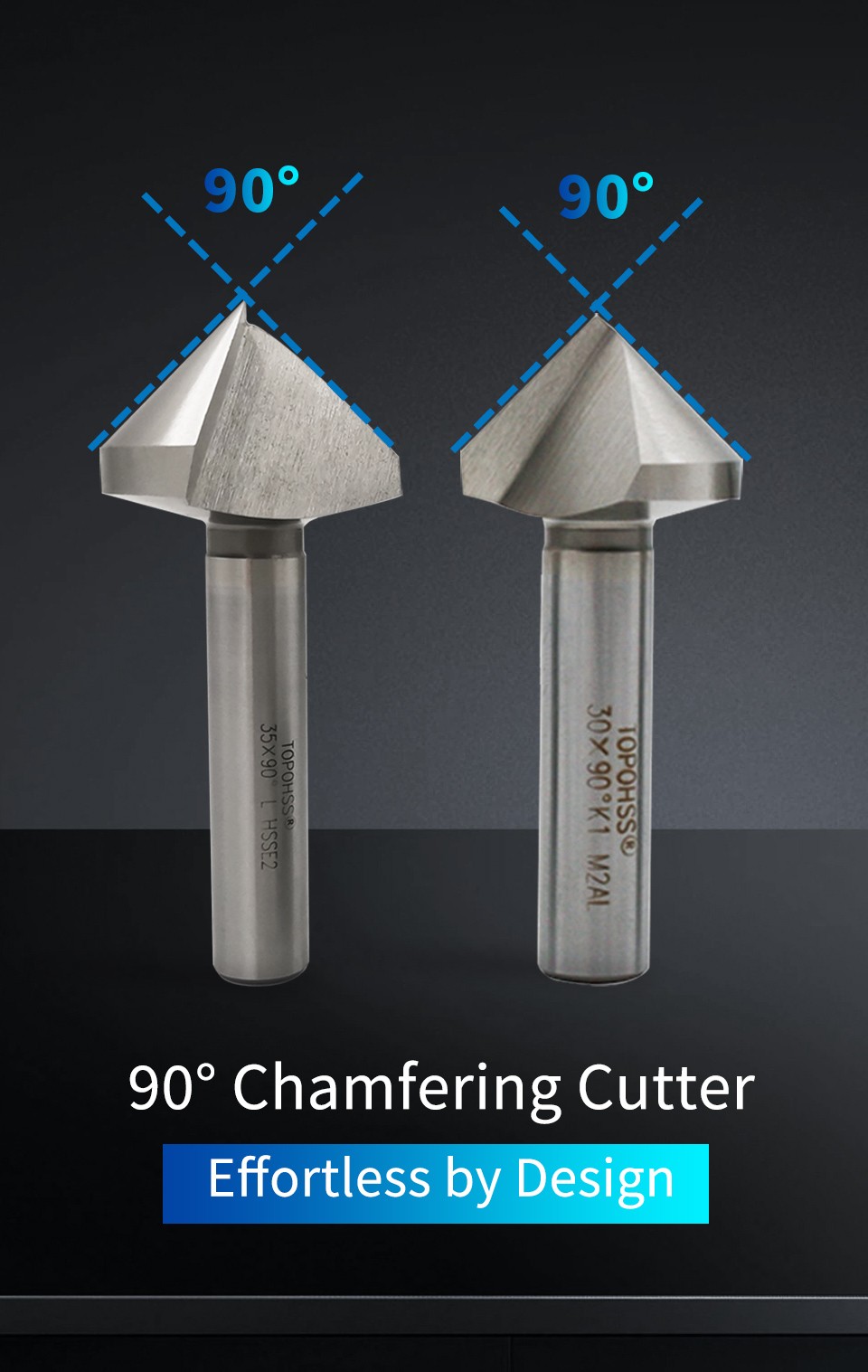

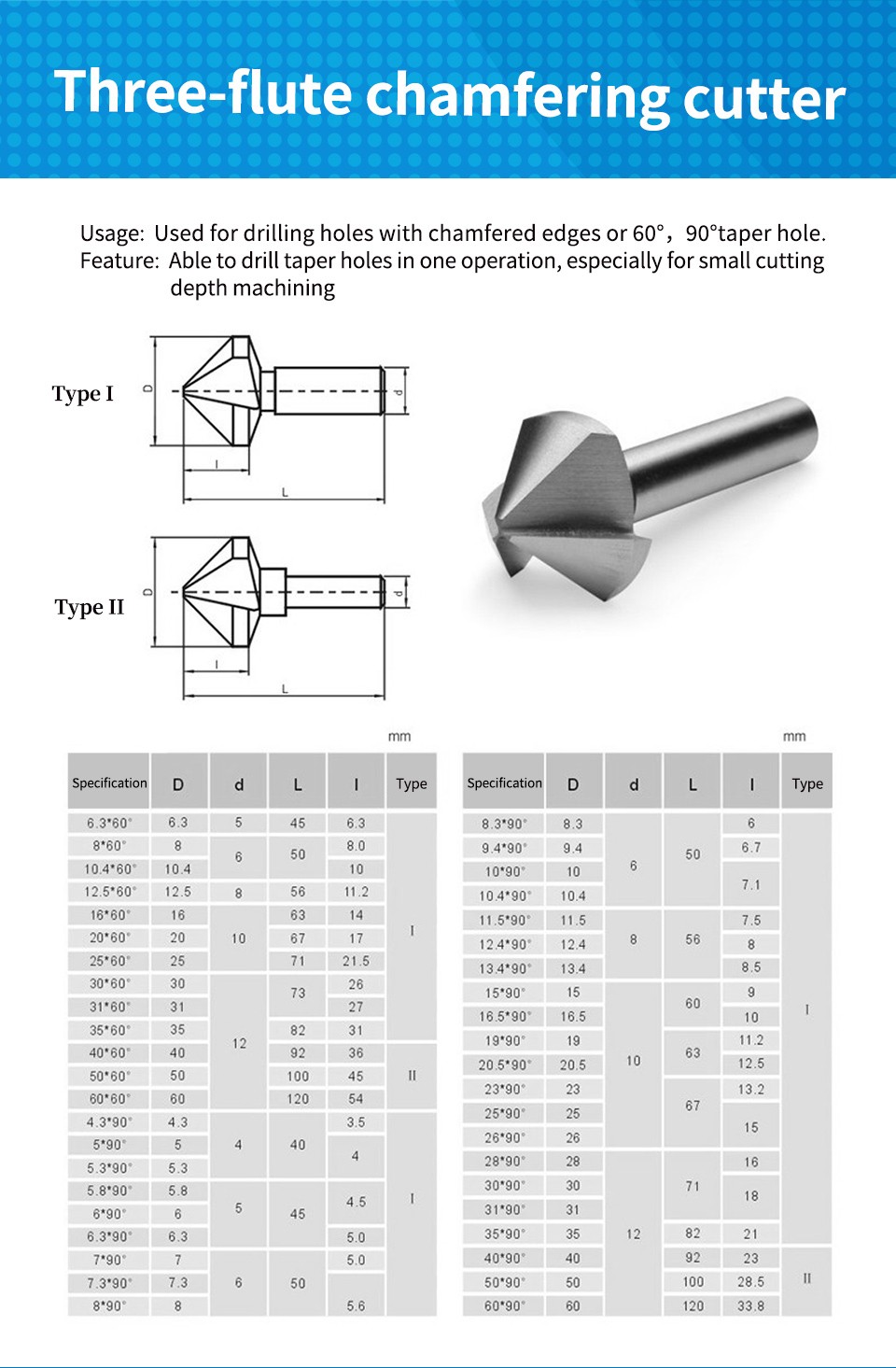

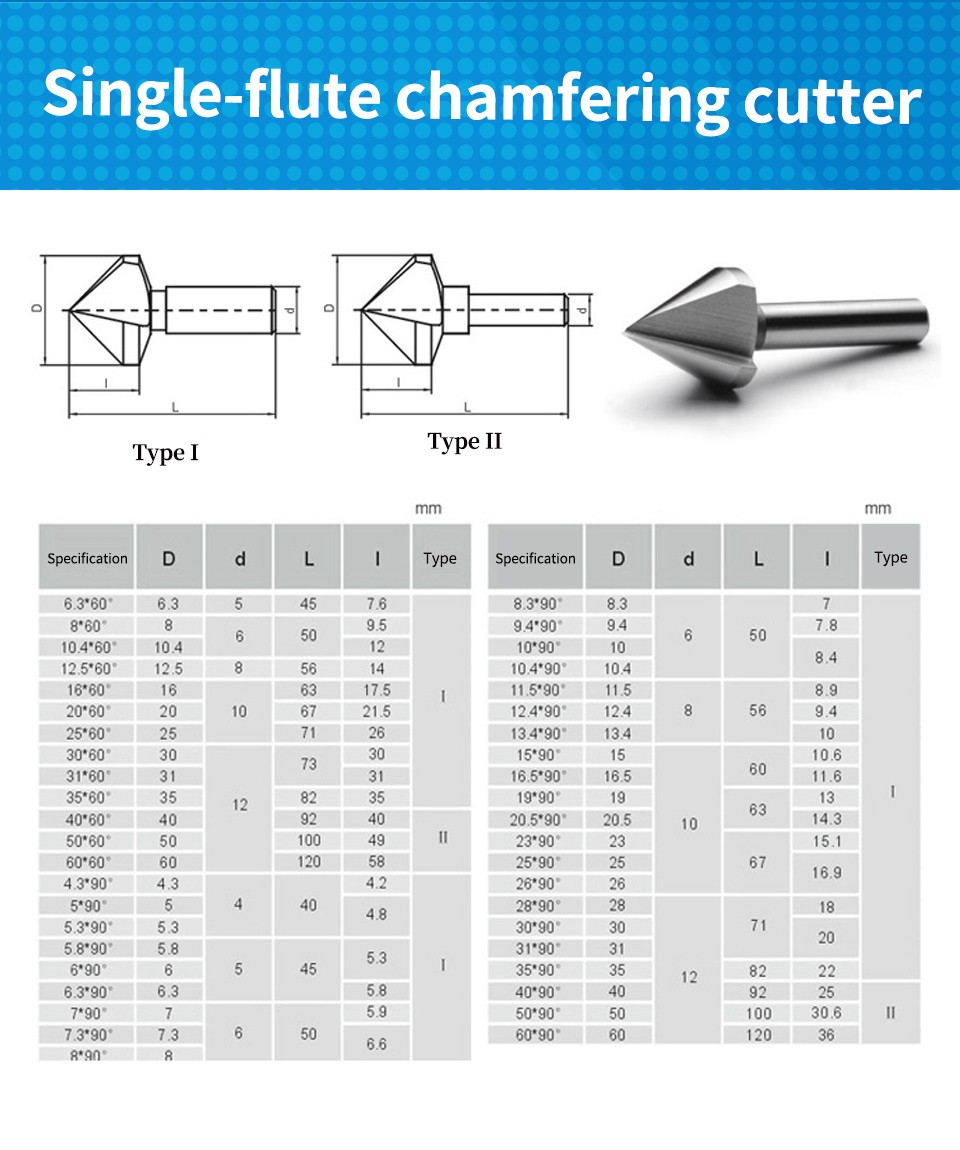

Name: Straight Shank Chamfering Tool – 1-flute or 3-flute option for 60°, 90°, 120° angles.

Material: HSS 6542 hardened to HRC 62-64°, tough edge for stainless, steel, iron, copper and aluminum.

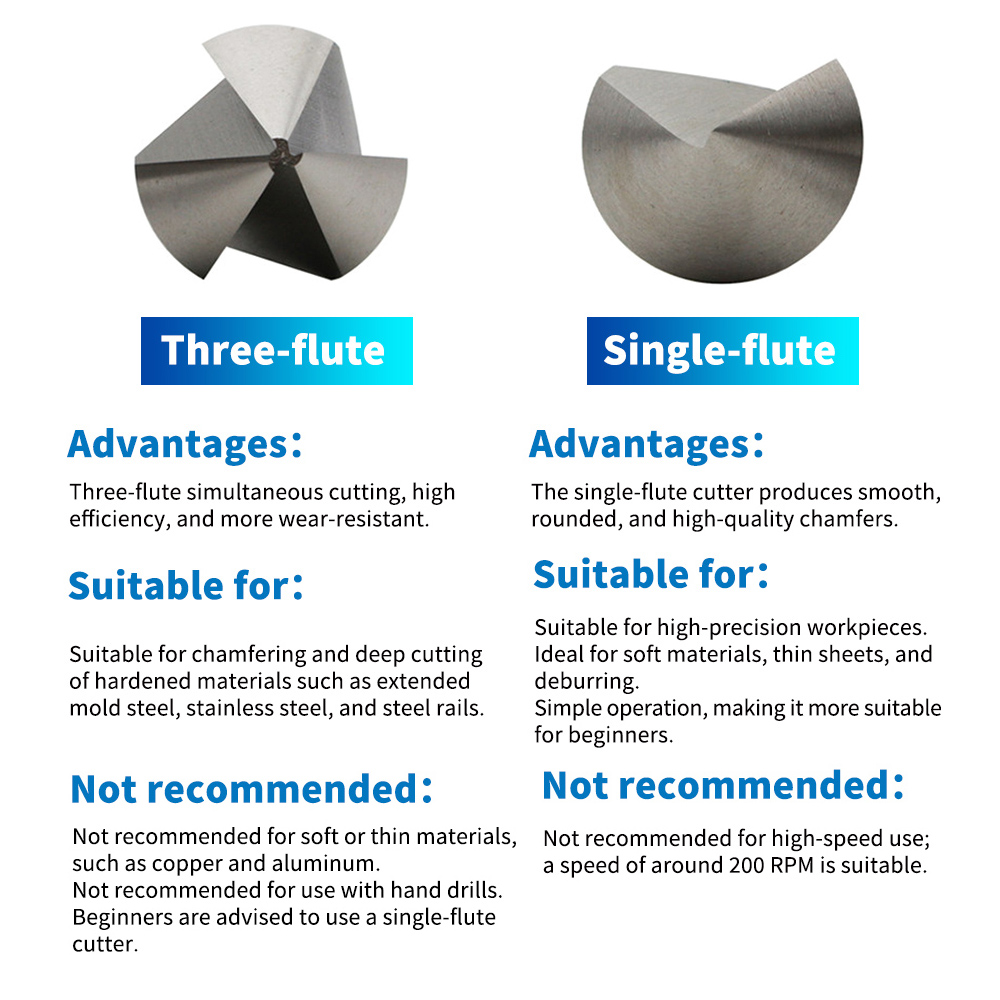

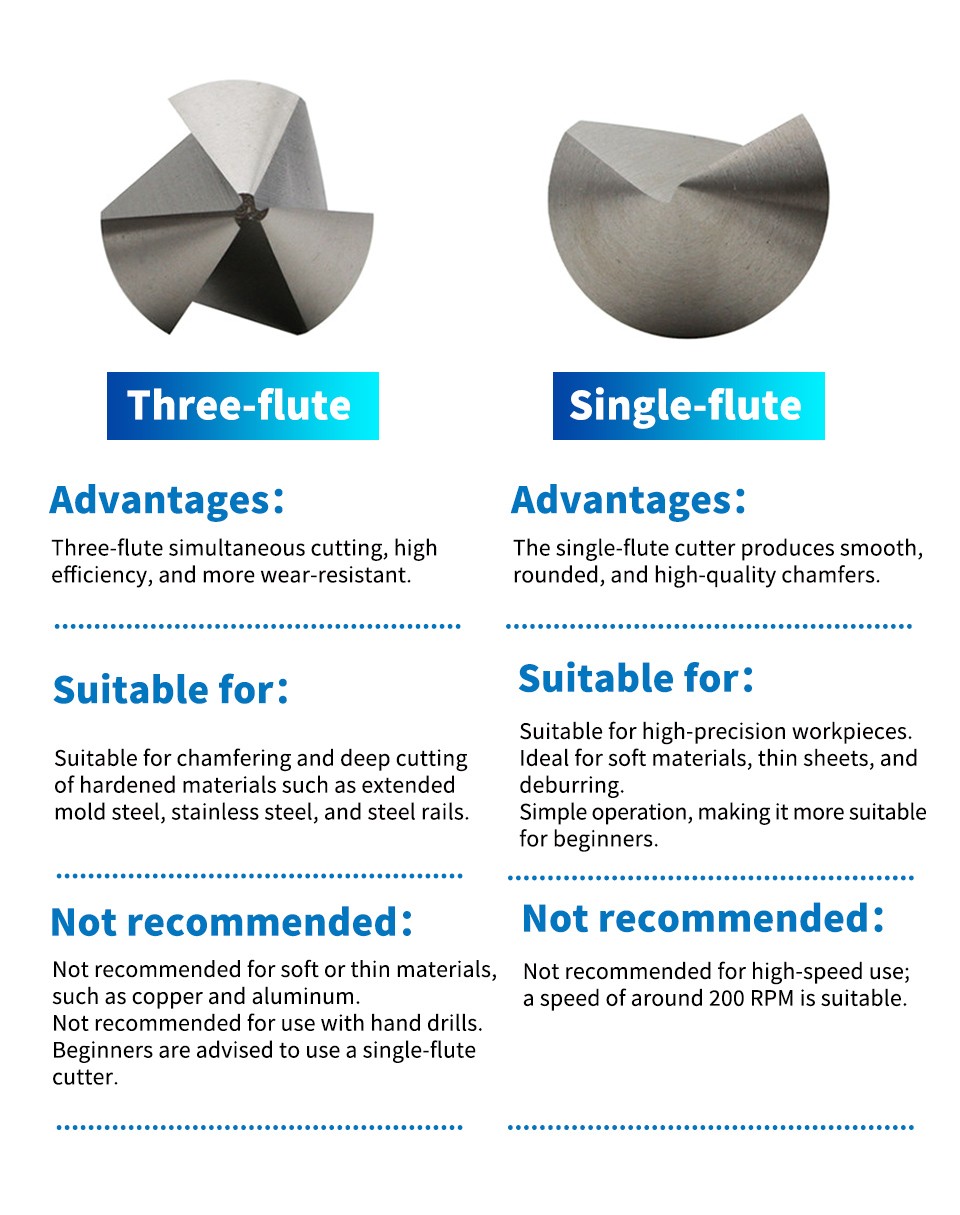

Single-edge version: one cutting edge, low feed force, ultra-smooth finish – ideal for soft materials like aluminum.

Triple-edge version: three edges share load, less wear per tooth, higher feed rate and longer tool life – perfect for hard steels.

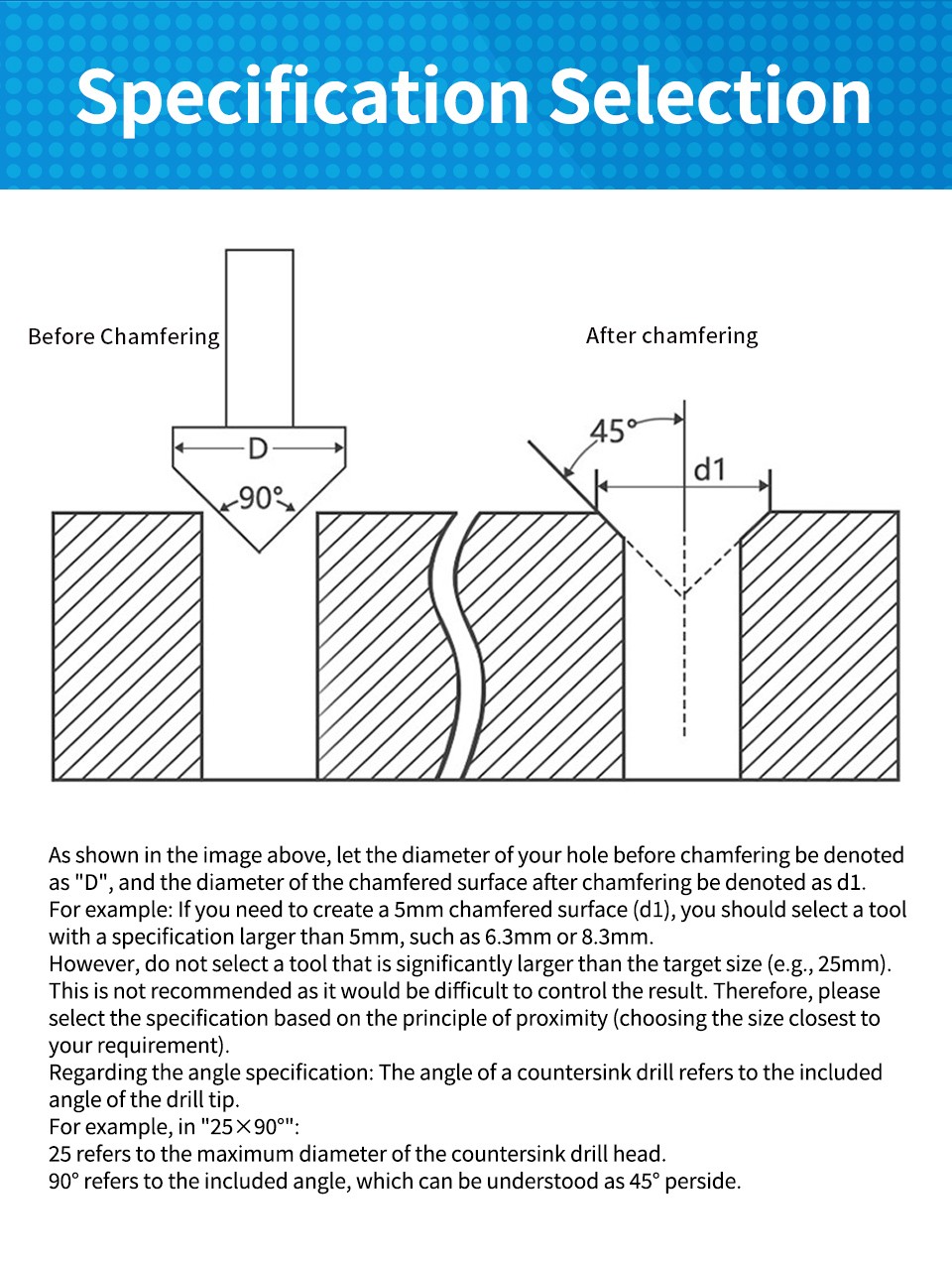

6-60 mm diameter range: covers M3-M36 screw clearances and inner-hole chamfers in one pass.

Straight shank h6 tolerance: zero run-out on ER, JT, Weldon arbors for chatter-free cutting.

One-pass taper forming: eliminates secondary machining, reduces cycle time and setup cost.

Light cutting depth design: minimizes heat, burrs and work-piece distortion on thin plates.

Single-edge/Triple-edge Straight Shank Chamfering Tool

Name: Straight Shank Chamfering Tool

Material: High-speed steel 6542

Hardness: HRC62-64°

Angle: 60°, 90°, 120°

Applications: Used for chamfering or tapering round holes in stainless steel, steel, iron, copper, aluminum, and other materials.

Features: Can complete the tapered surface machining in one pass, suitable for small cutting depth machining.

Single-edge: Suitable for soft materials, only one cutting edge bears the force, resulting in a smoother chamfer. Suitable for softer materials such as aluminum, but slightly less efficient than triple-edge.

Triple-edge: Suitable for hard materials, all three edges bear the force evenly, each edge experiences less stress, resulting in greater durability and higher efficiency.

Precautions:

1. The three-blade blade is exceptionally sharp and suitable for high-precision equipment such as machining centers. It may cause vibration when used with ordinary bench drills. The three-blade blade must not be used with electric drills.

2. It is not recommended for use on ceramic tiles, concrete, walls, stone, etc.