Your Trusted Source for a Complete Line of Internal Cooling Tools

Advantages of Internally Cooled Toolholders:

1. Cooling and Chip Evacuation

Traditional external cooling methods spray coolant onto the tool and workpiece machining area. This makes it difficult for the coolant to penetrate the cutting edge where cooling is most needed, resulting in limited cooling effectiveness. Internally cooled toolholders, on the other hand, deliver coolant directly to the cutting area through channels within the toolholder. This quickly dissipates cutting heat, lowers tool temperature, reduces tool wear and deformation caused by high temperatures, and extends tool life.

The cutting process generates a large amount of chips, especially in deep hole machining. Poor chip removal can cause them to entangle with the tool, affecting machining accuracy and even damaging the tool. The high-pressure coolant sprayed by internally cooled toolholders effectively flushes the chips, allowing them to be smoothly expelled from the machining area, ensuring continuous and stable machining.

2. Machining Accuracy and Surface Quality

Because internally cooled toolholders can promptly dissipate cutting heat, they effectively reduce thermal deformation caused by elevated workpiece temperatures. This is crucial for machining precision parts requiring high accuracy. For example, in the aerospace industry, when machining high-precision engine components, internally cooled toolholders ensure that part dimensional tolerances are kept within extremely tight limits. A stable machining environment and effective chip evacuation reduce chip scratches on the machined surface, reducing workpiece surface roughness and achieving better surface quality. In automotive parts machining, engine blocks, cylinder heads, and other parts machined with internally coolant toolholders achieve significantly improved surface quality and reduce the workload in subsequent grinding and other processes.

Processing Efficiency: Because tool cooling and wear are improved, cutting parameters such as cutting speed and feed rate can be appropriately increased, thereby improving machining efficiency. For example, in turning, under the same machining conditions, using internally coolant toolholders can increase machining efficiency by 15%-25% compared to traditional toolholders.

Internally coolant toolholders reduce the number of downtimes for cleaning and tool changes caused by tool wear and chip entanglement, shortening auxiliary time and increasing equipment utilization.

One-stop shopping

Internal coolanttoolholder series

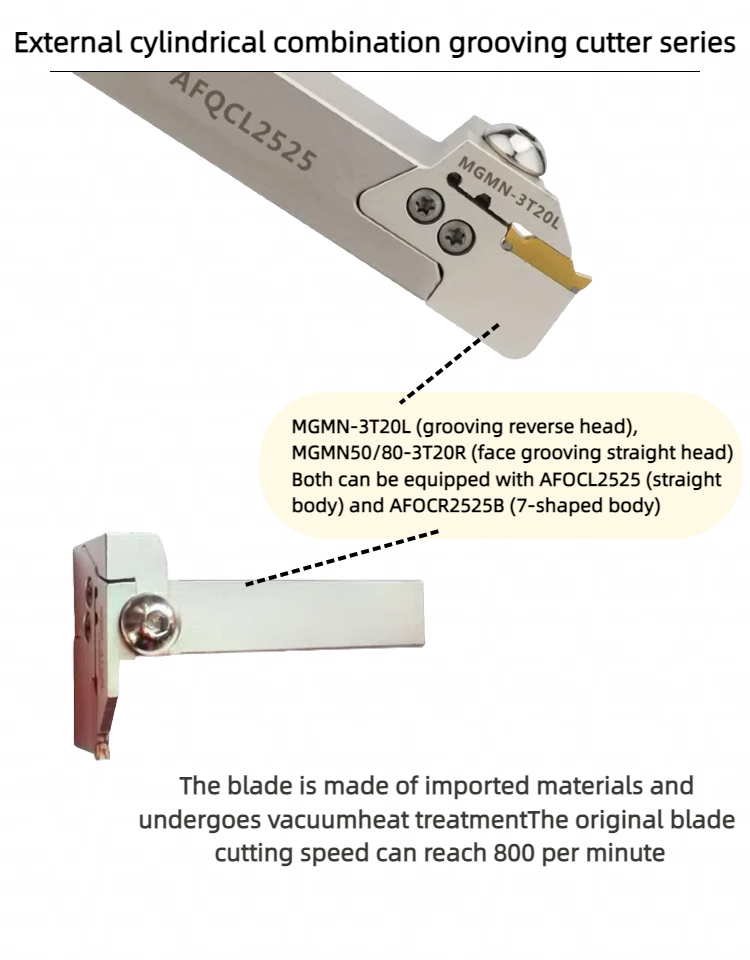

External cylindrical combination grooving cutter series

MGMN-3T20L(grooving reverse head)MGMN50/80-3T20R (face grooving straight head)Both can be equipped with AFOCL2525 (straightbody)and AFOCR2525B (7-shaped body)

The blade is made of imported materials andundergoes vacuumheat treatmentThe original bladecutting speed can reach 800 per minute

Inner hole combination series

The tool body can be installed with all tool heads, for example:DT20R-M(die steel tool body),DT20R-C(tungsten steel tool body)can be installed with all tool heads of the same diameter, such asMGMN2720R-3T6(grooving),DT20-SCLCR09(boring),DT20-SNR16(threading),DT20-MWLNL08(boring),etc.

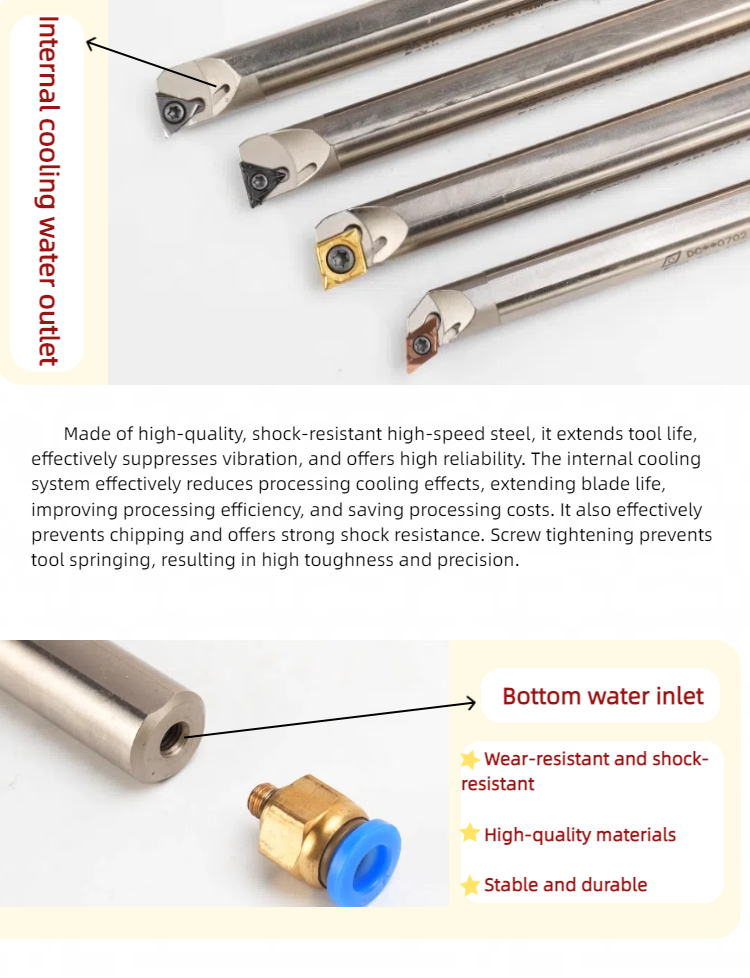

Internal cooling water outlet

Made of high-quality, shock-resistant high-speed steel, it extends tool life,effectively suppresses vibration, and offers high reliability. The internal coolingsystem effectively reduces processing cooling effects, extending blade life,improving processing efficiency, and saving processing costs. lt also effectivelyprevents chipping and offers strong shock resistance. Screw tightening preventstool springing, resulting in high toughness and precision.

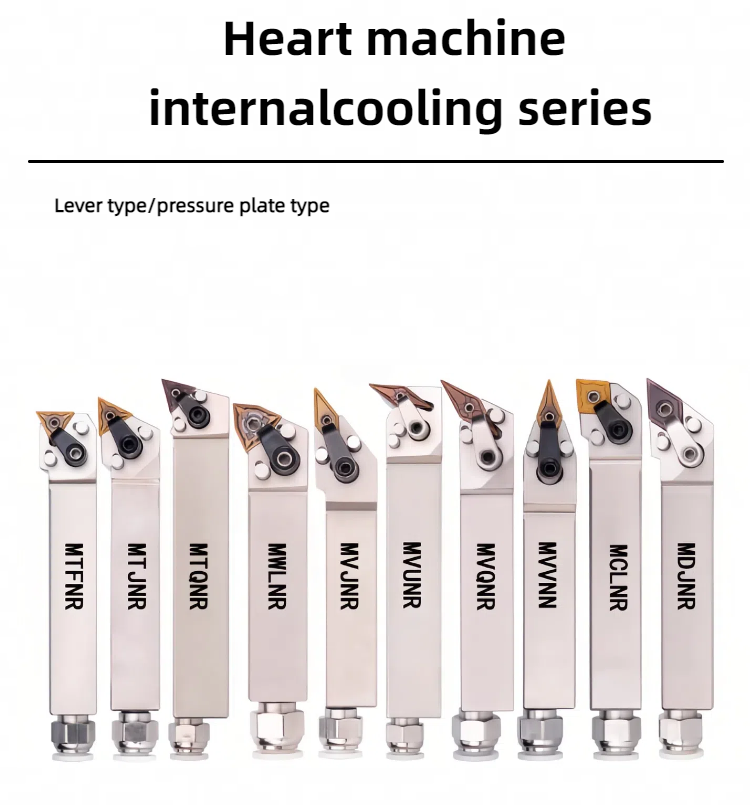

Heart machineinternalcooling series

Lever type/pressure plate type

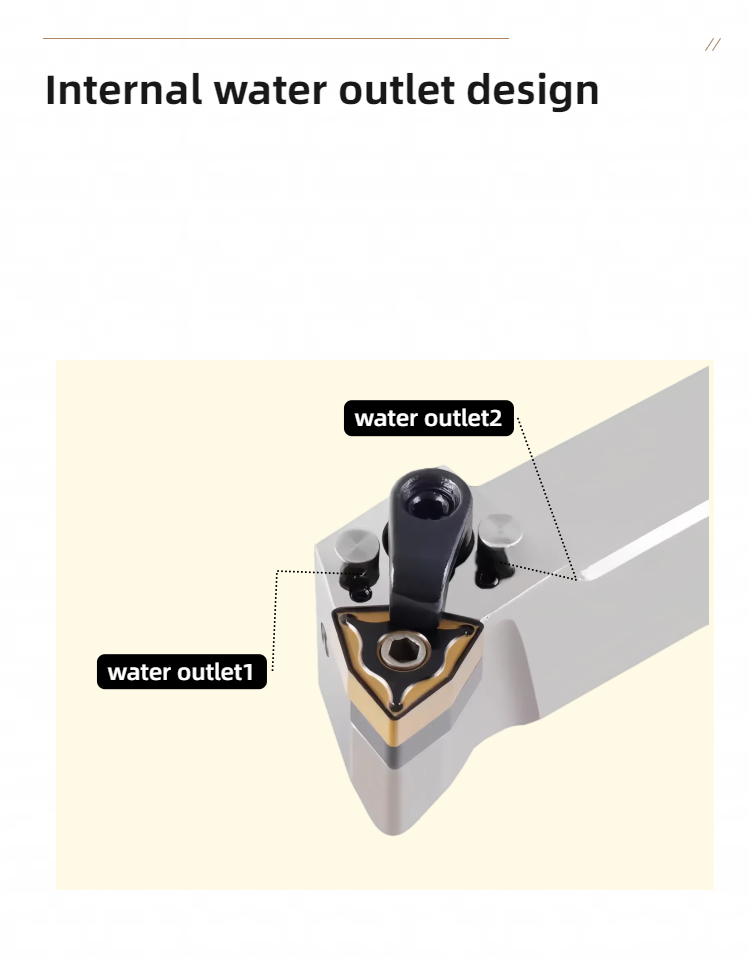

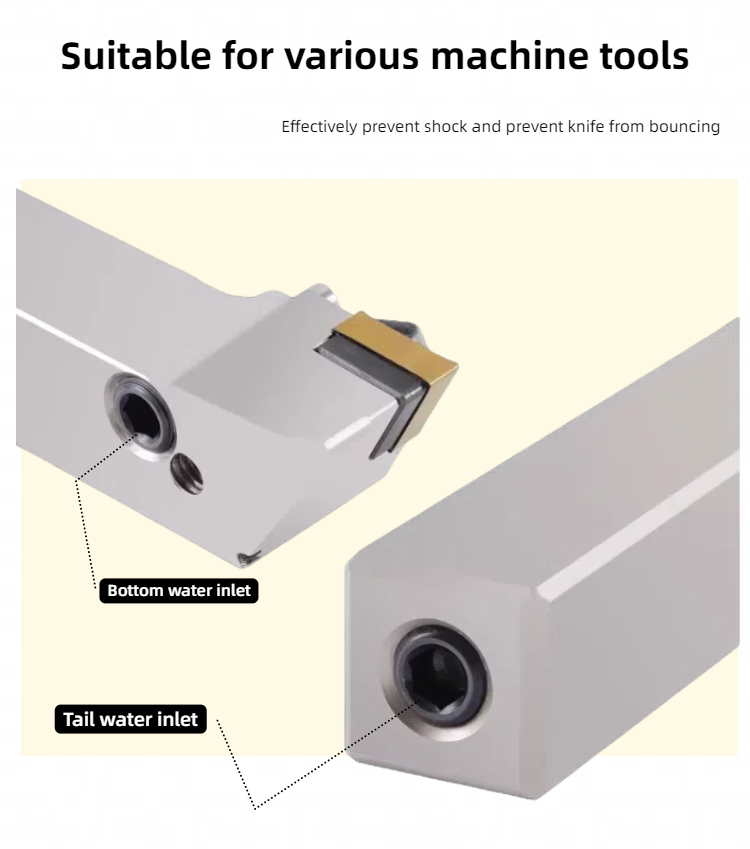

Internal water outlet design

Suitable for various machine tools

Effectively prevent shock and prevent knife from bouncing