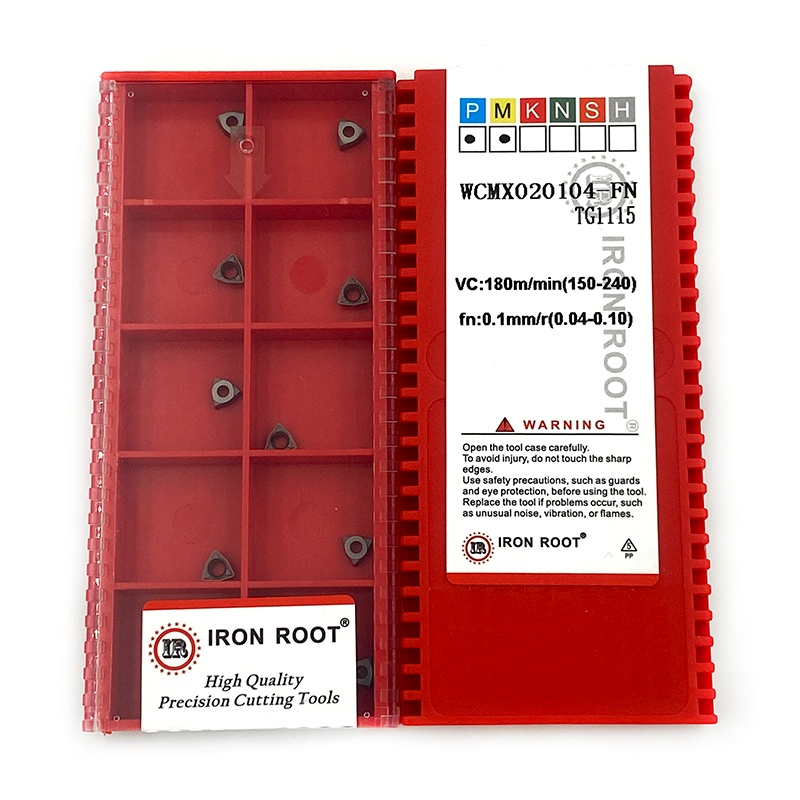

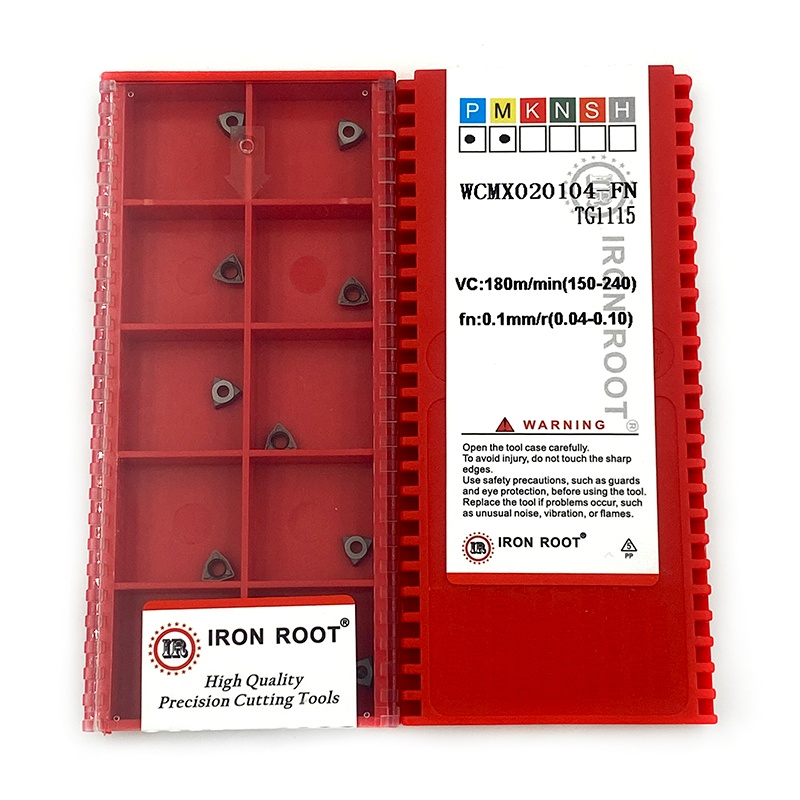

CNC U drill blade WCMX020104-FN

High wear resistance and toughness

Adopting a new carbide substrate, it has high wear resistance and toughness while providing better strength.

Advanced coating technology

Using advanced PVD/CVD coating technology and gradient sintering technology, the wear resistance of the cutting edge is significantly improved.

Multiple chipbreaker designs

Provide a variety of chipbreakers and coating options, suitable for processing different materials, and can achieve efficient chip removal and high-performance processing.

Long life and high cost performance

The blade has a long service life and is competitively priced, which can reduce processing costs.

Optimized processing parameters

Suitable for a variety of processing scenarios, including stainless steel, steel parts and high-hardness materials, and can adjust parameters according to specific needs to achieve the best processing results.

Strong versatility

This model of blade is suitable for a variety of U-drill systems, has strong adaptability, and can be widely used in CNC lathe and milling machine processing.

Good user evaluation

According to user feedback, the blade is reliable in quality, excellent in processing performance, and has good after-sales service.

Customized service

Some suppliers provide non-standard design and manufacturing services, and can customize blades according to customers' specific needs.

In the field of modern manufacturing, especially in CNC machining and precision drilling applications, it is very important to choose an efficient, durable and reliable blade. WCMX020104-FN TG1115 U drill blade has become the first choice of many industrial users due to its excellent performance and wide range of applications.WCMX020104-FN TG1115 U drill inserts use an advanced carbide matrix, a material known for its high strength, high hardness and excellent wear resistance. Combined with TG1115 coating technology, the inserts exhibit excellent impact resistance and wear resistance during processing. This coating is particularly suitable for processing stainless steel and high-hardness steel parts, which can effectively reduce tool wear and extend tool life. Whether it is roughing or finishing, the WCMX020104-FN insert can provide stable cutting performance to ensure efficient and accurate processing.

The chip breaker design of the insert is one of the key factors in its performance. The WCMX020104-FN TG1115 adopts a classic chip breaker structure that can effectively control the formation and discharge of chips. This design not only reduces the possibility of chip accumulation, but also improves the surface quality of the machined surface. When machining high-hardness materials, good chip breaking performance can significantly reduce tool wear, while reducing machining interruptions caused by chip accumulation, thereby improving overall machining efficiency.

| Product Brand | IRON ROOT |

| Outer diameter | 2mm |

| Inner diameter | 1mm |

Belongs to | U-Drill Series |

| Coating Technology | PVD/CVD |

| Type | Cutting Tool |

The WCMX020104-FN insert has a smaller size, suitable for small-diameter drilling operations, and can be adapted to a variety of U-drill systems. This versatility allows the insert to perform well in different processing scenarios, whether it is a CNC lathe or a milling machine, it can be easily adapted. In addition, the insert's dimensional accuracy and processing stability make it an ideal choice for high-precision processing, which can meet the diverse needs of different users.

In terms of processing efficiency, the WCMX020104-FN TG1115 U drill insert performs well. Its high wear resistance and impact resistance enable the insert to maintain stable performance during long-term processing, reducing the frequency of replacement due to tool wear. This means that users can not only reduce tool costs, but also improve production efficiency and shorten processing cycles. From an economic point of view, choosing the WCMX020104-FN insert is undoubtedly a cost-effective choice. The WCMX020104-FN TG1115 U drill insert is suitable for a variety of processing scenarios, especially in the processing of stainless steel, steel parts and high-hardness materials. It is widely used in industries such as automotive manufacturing, aerospace, and mechanical processing, and can meet processing needs from simple to complex. Whether it is small-batch production or large-scale manufacturing, this insert can provide reliable processing performance and ensure processing quality.