MB05 - GR100 - 2.3 - D08 Comma slot blade: a great tool for small hole slotting

1. Precise adaptation to small hole inner hole processing:

Diameter compatibility

Cutting depth capability

2. Wear resistance advantages of materials and coatings:

GR100 material characteristics

Coating technology support

3. Structural design optimizes processing efficiency:

Comma groove design

Edge treatment

4. Adaptability and economic advantages:

Versatility

Cost-effectiveness

5. Processing accuracy and stability:

Dimensional accuracy

Anti-vibration design

Detailed Showcase

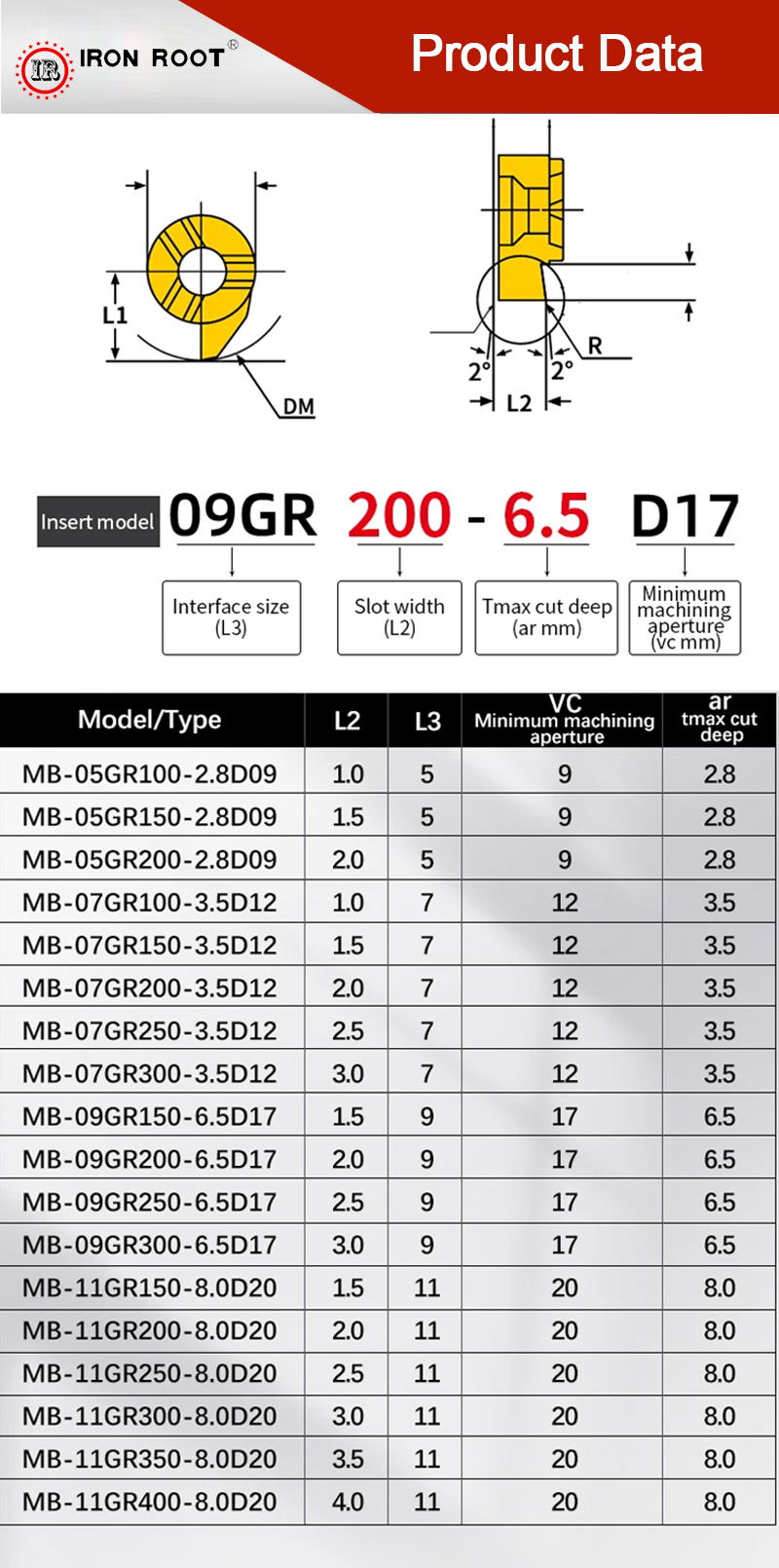

MB05: Indicates the specification model of the blade, which represents the basic parameters such as the size, shape, thickness, etc. of the blade. "Blade No. 5" usually corresponds to a specific tool bar and installation size.

GR100: Indicates the material, coating or process characteristics of the blade. 100" may be the specific parameters of the material or treatment method.

2.3: Indicates that the groove depth of the blade is 2.3 mm, which is an important dimensional parameter when the blade is used for processing, and determines its cutting depth in slotting or grooving processing.

D08: Indicates that the tool bar diameter applicable to the blade is 8 mm. "D" is usually the abbreviation of "Diameter". This parameter determines the matching size of the blade and the tool bar, ensuring that the blade can be correctly installed on the corresponding tool bar for processing.

Product parameters

High-speed steel

The quenched and hardened tool bar is wear-resistant and has a long service life. It has high hardness and is not easy to deform. It can be used for strong cutting, effectively saving man-hours and improving efficiency.

Sharp and wear-resistant Highly specialized

The blade is coated with a 1000-degree stress accumulation method. The coating is thicker, the processing is more stable and wear-resistant.

Good adaptability

The tool bar is heat-treated before processing, which is not easy to produce physical deformation. The blade fits tightly with the cutter head and the blade will not crack.

Product Data

Product Advantages

Material and performance advantages

Wear-resistant materials guarantee life

If "GR200" is associated with a material/coating system, it has high hardness and strong wear resistance. When processing difficult-to-cut materials such as stainless steel and alloy steel, the life of ordinary blades is increased by 30%-50%, reducing the frequency of tool change and improving production line efficiency.

Coating and cutting edge optimization

High-temperature deposition coating technology may be used to reduce cutting friction and inhibit built-up edge. At the same time, the cutting edge is passivated/mirror-finished, with low cutting resistance and high surface finish, reducing subsequent polishing processes, and is suitable for parts with high-precision surface requirements

Processing efficiency and stability advantages

Chip breaking and chip removal design

Comma groove structure + groove parameter optimization can stabilize chip breaking (such as curling chips into small segments for discharge), avoid chips entangled with tools/workpieces, especially suitable for high-speed cutting scenarios of CNC lathes and automatic lathes, ensure processing continuity, and reduce the risk of downtime and scrapping due to chip problems.

Vibration resistance and rigidity adaptation

The rigid design of the tool body/tool bar is suitable for small inner hole processing, with low vibration during cutting, and "chatter marks" are not easy to appear during deep groove processing, ensuring processing stability and reducing defective product rate.

.