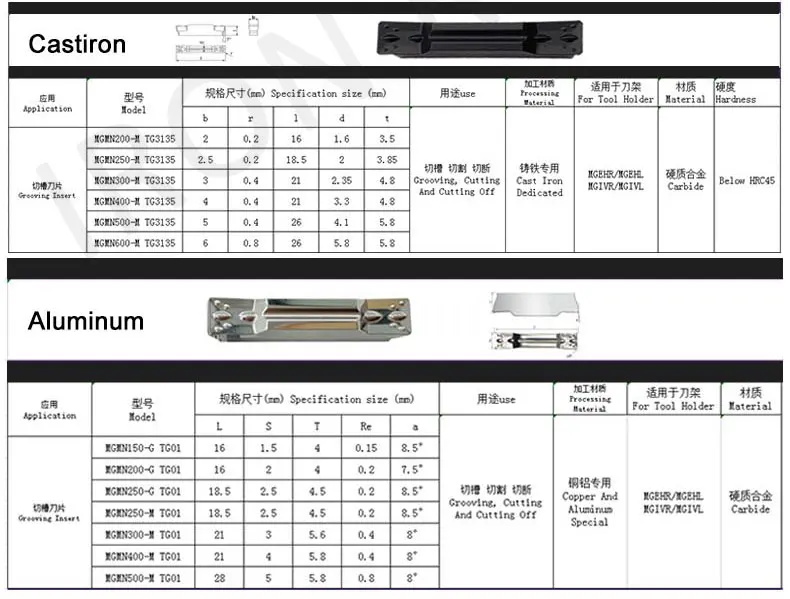

IRON ROOT SP200/SP300 /SP400 /SP500 /TG1225 Grooving Carbide inserts

Made of premium carbide: wear-resistant, heat-resistant, long-lasting, less frequent replacement.

Fits diverse grooving tasks (internal/external grooving, parting); IRON ROOT TG1225’s unique geometry boosts versatility.

Optimized chip-breaker design: smooth chip evacuation, no buildup issues.

Precisely ground edges: accurate cuts, reducing post-machining work.

Coated models (e.g., TiN) enhance hardness, reduce friction, extend life.

Compatible with standard CNC lathes: easy integration, cost-efficient.

The IRON ROOT SP200/SP300/SP400/SP500/TG1225 grooving carbide inserts are crafted from high-grade tungsten carbide, a material renowned for its exceptional hardness and resistance to wear and high temperatures.

This robust construction allows them to thrive in the demanding environment of IRON ROOT CNC lathe operations, where they consistently deliver reliable performance even during extended machining sessions. Whether tackling carbon steel, stainless steel, or various ferrous materials, these inserts maintain their sharpness and structural integrity, significantly extending their service life compared to standard alternatives and reducing the need for frequent tool changes.