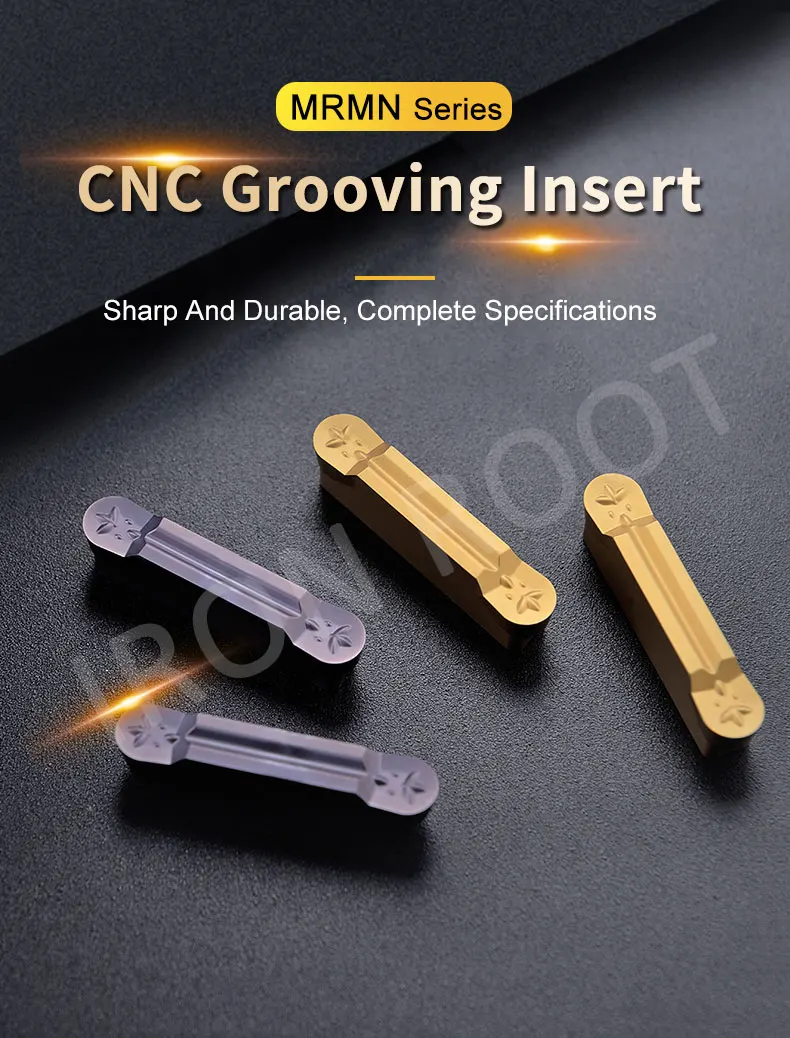

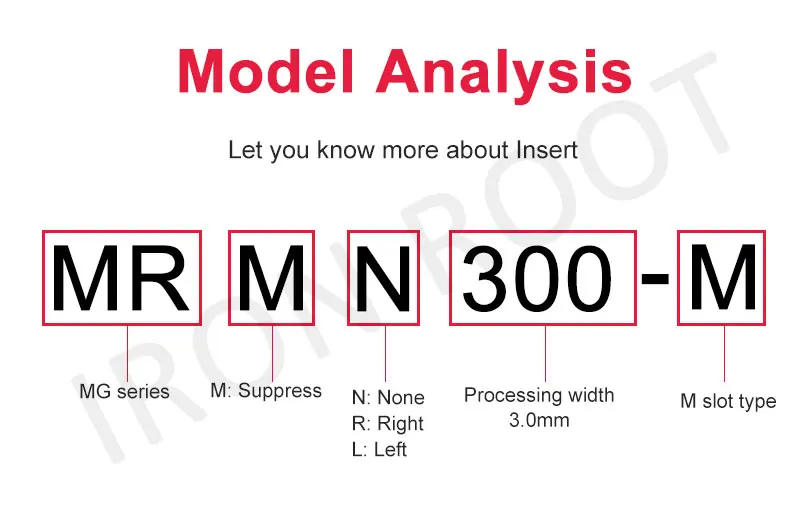

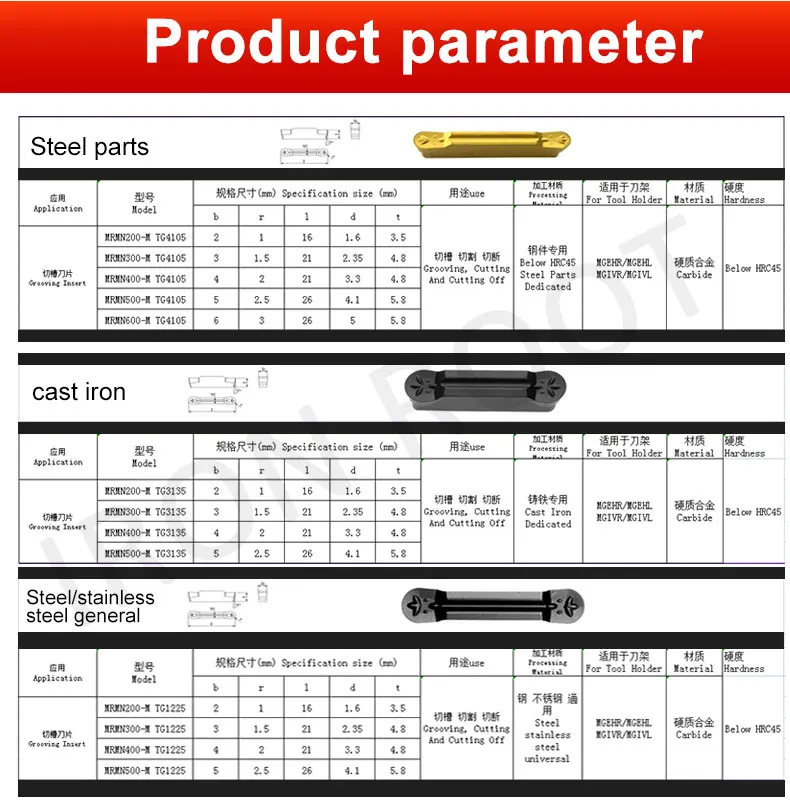

MRMN300-M MRMN400-M MRMN500-M Insertos de carburo Inserto ranurado para acero inoxidable

1.Superior Material Compatibility

2.Enhanced Wear Resistance

3.Precision Thread Geometry

4.Heat Dissipation Design

5.Versatile Application Range

6.Reliable Chip Control

- Producto químico muy preocupadoNingunoDurezaHRC45

- RevestimmientoPVDUsoHerramienta de torneado exterior

- OrigenCN(Origen)Número de modeloMRMN

Designed exclusively for challenging stainless steel materials, the MRMN300-M, MRMN400-M, and MRMN500-M inserts are premium grooved carbide threading tools that combine advanced material science with precision geometry to deliver exceptional performance in high-strength, corrosion-resistant alloy applications. Ideal for both roughing and finishing operations, these inserts set a standard for reliability and efficiency in industries demanding tight tolerances and superior surface finishes.

Aerospace: Turbine parts, fasteners, and hydraulic components.

Medical Devices: Surgical instruments, implantable components, and diagnostic equipment.

Automotive: Exhaust systems, transmission parts, and engine components.

Industrial Equipment: Valves, pumps, and pipe fittings for corrosive environments.

Why Choose MRMN Inserts?

Reduced Downtime: Long tool life and reliable chip control minimize interruptions for insert changes or chip clearing.

Cost Efficiency: Fewer tool replacements and improved machining speeds lower overall production costs.

Quality Assurance: Consistent thread accuracy and surface finish meet or exceed international standards (ISO, ASME, JIS).