Superior Material Quality: Crafted from high - grade carbide, these inserts offer exceptional hardness, outstanding wear resistance, and remarkable heat resistance. This enables them to maintain excellent cutting performance even under high - speed machining and elevated temperature conditions, significantly extending the tool's lifespan compared to ordinary inserts.

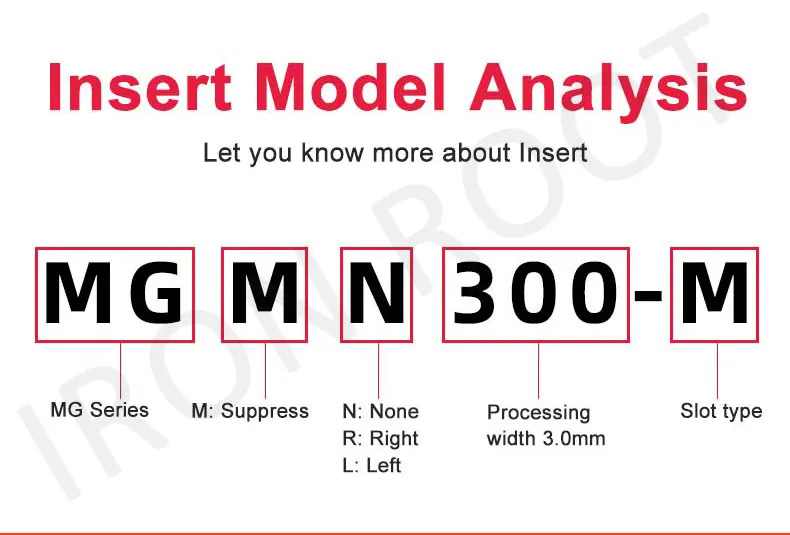

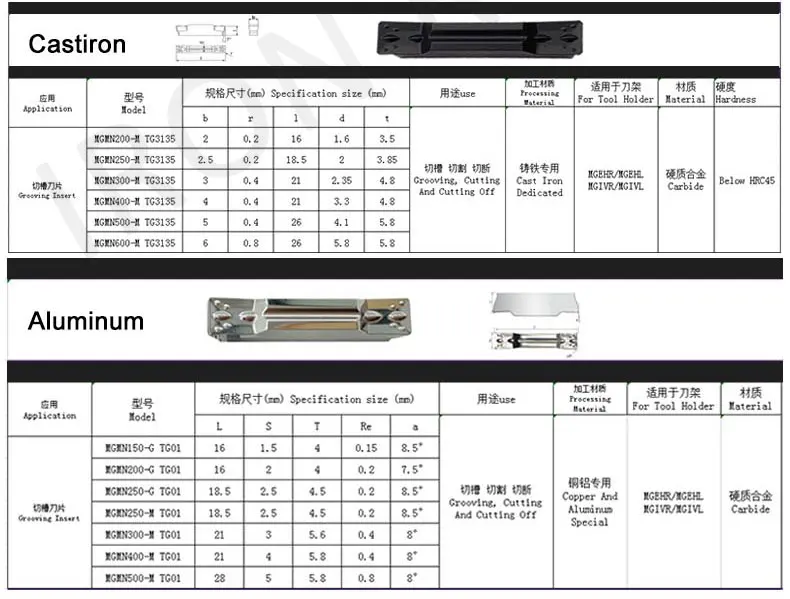

Precise and Standardized Sizing: The clear and distinct model specifications, such as MGMN200 - DR and MGMN500 - DR, with specific dimensional references, ensure that users can accurately select the most suitable insert for different machining requirements. The precise dimensions contribute to consistent and high - quality machining results.

Specialized Grooving Design: Specifically designed for lathe grooving and cutting operations, these inserts can achieve efficient and accurate grooving and cutting of workpieces. Their unique cutting edge geometry reduces cutting forces during machining, enhancing the stability of the cutting process and minimizing the likelihood of workpiece deformation.

Excellent Chip Control: With a special chip - breaking groove design, like the central chip - breaking groove, these inserts ensure balanced cutting. The special raised surface positions help control chip flow during external cutting, resulting in smooth chip evacuation. This not only improves machining efficiency but also prevents chips from interfering with the machining process, thus ensuring the quality of the machined surface.

Versatile Machining Applications: Suitable for machining various materials, including stainless steel, especially austenitic stainless steel, and capable of low - speed cutting of heat - resistant alloy steels. This wide range of material adaptability makes the inserts highly applicable in different industrial machining scenarios, providing users with more flexibility in machining operations.

Nano - Blue Coating Advantage: The CNC Nano blue feature, likely referring to a nano - blue coating, offers enhanced surface properties. This coating can reduce friction between the insert and the workpiece, lower cutting temperatures, and further improve the wear resistance of the insert. As a result, it helps achieve better surface finish of the machined parts and improves the overall machining efficiency.