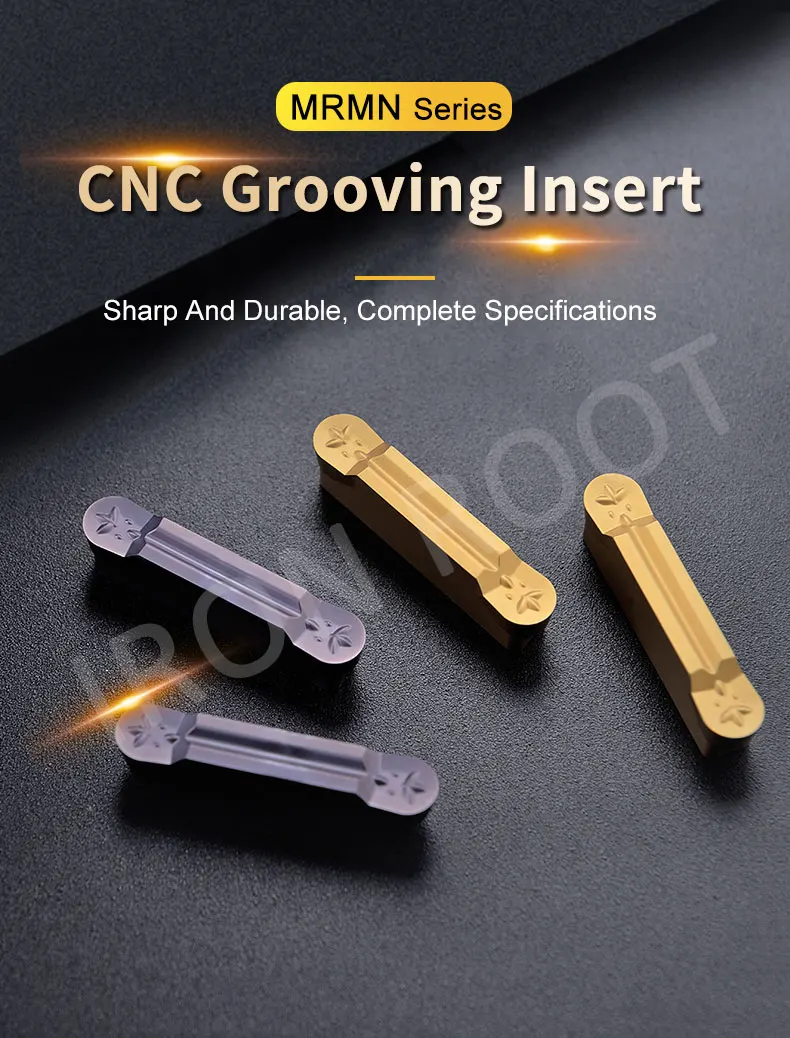

"The Unstoppable Edge": How MRMN Carbide Inserts Are Conquering the "Nightmare Metal" of Machining Move over, stainless steel—there’s a new sheriff in town, and it’s turning your notorious "gumminess" into a walk in the park. Machinists worldwide are buzzing about the MRMN300-M/MRMN400-M/MRMN500-M carbide threading inserts, the first tools designed to tame the sticky, heat-generating, tool-destroying chaos of machining austenitic and duplex stainless steels. Say goodbye to frequent insert changes, botched threads, and overheated workshops—these inserts are so tough, they’re being called "the superheroes of the CNC world."

![]()

"Stainless Steel Was Our Kryptonite… Until Now"

For decades, machining stainless steel has been a headache. Its high ductility causes chips to weld onto tools, its poor thermal conductivity turns cutters into ovens, and achieving a precise thread in grades like 304 or 316L felt like winning a lottery. But engineers at [Company Name] decided to fight back with a trio of inserts built like threading ninjas.

"Traditional inserts would dull after 20 parts; now we’re hitting 200 with MRMN500-M," raves Jake Turner, a CNC operator at an aerospace shop. "It’s like the insert has a force field against heat and stickiness. Even our grumpiest lathe operator is smiling—no more cussing at broken threads!"

The Secret? A Triple Threat of Science and Smarts

What makes these inserts so revolutionary? Three game-changing features that read like a machining wishlist:

The "Anti-Stick" Supercoating:

A nanometer-thin AlTiN layer (harder than diamond, literally) repels stainless steel chips like Teflon repels spaghetti. "It’s not just a coating—it’s a force multiplier," explains materials scientist Dr. Elena Marquez. "We tested it against 1000°F heat and saw 50% less wear than standard coatings. The insert stays sharper, longer."

Threading Geometry That’s a Math Genius:

The MRMN series uses a proprietary "precision pitch profile" that’s calculated to 0.001mm tolerances. "Even on the gummiest 316L, the threads come out smoother than a polished submarine hull," jokes mechanical engineer Carlos Rivas. "We’re hitting ISO 6g specs without needing a second pass—unheard of in our shop."

Chip Control That’s a Master Chef:

The grooved design (inserto ranurado) doesn’t just break chips; it spits them out in perfect curls, like a barista crafting latte art. "No more chip clogs or scratched surfaces," says automotive manufacturer Lisa Chen. "It’s like the insert has a built-in vacuum for chips—our machines run non-stop now."

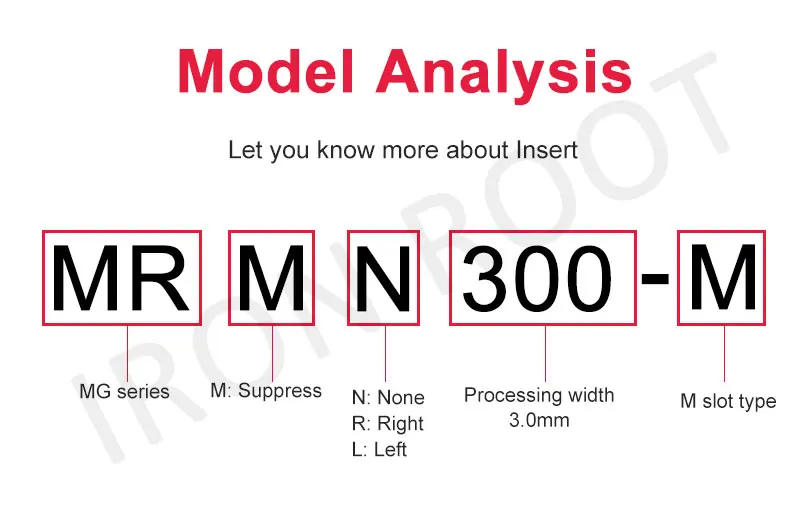

![]()

From Medical Implants to Rocket Engines: Where Precision Can’t Afford a Mistake

The inserts are already heroes in industries where failure is not an option:

Even DIY hobbyists are obsessed: "I machined a stainless steel espresso machine part that fit perfectly on the first try," gushes maker enthusiast Tomás Vega. "Normally, that’s a 3-day headache. Now it’s a lunchbreak project."

The Machinist’s Anthem: "Less Downtime, More Profit"

Shop owners are singing a new tune: fewer tool changes mean more parts per hour. A mid-sized shop in Germany reported a 40% reduction in tooling costs after switching to MRMN inserts, thanks to their 超长 lifespan (some operators claim they’ve used the same insert for a month straight). "It’s not just about the inserts—it’s about reclaiming our days," says Turner. "We used to waste 30 minutes a day changing inserts. Now? We’re using that time to make money."

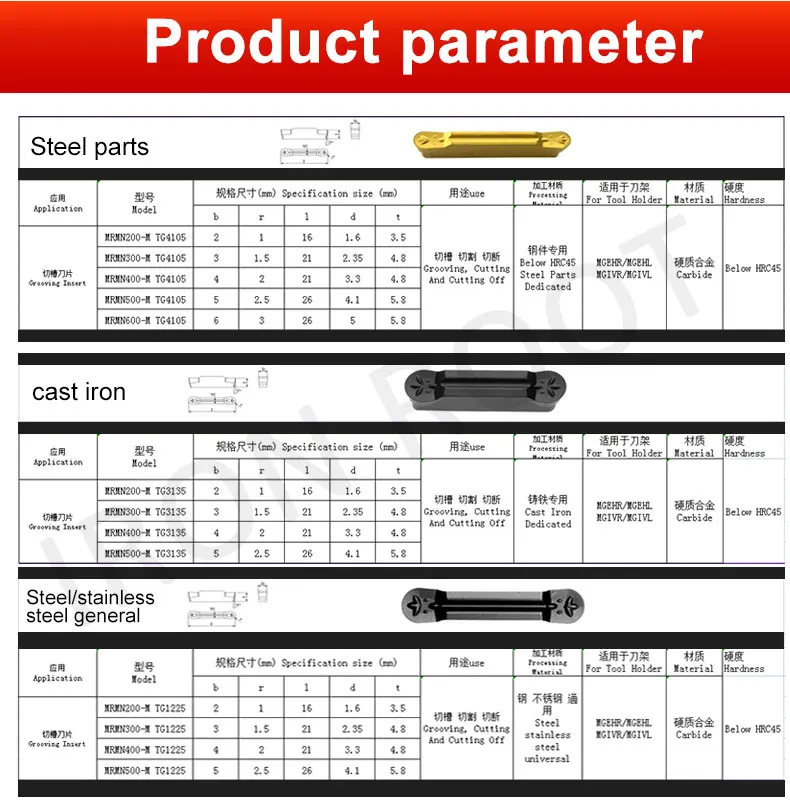

![]()

Ready to Dethrone the Nightmare Metal?

As the machining world shifts to tougher, more exotic materials, the MRMN series is leading the charge. "Stainless steel doesn’t scare us anymore," says Dr. Marquez. "These inserts prove that with the right technology, even the most stubborn materials can be turned into precision parts—efficiently, reliably, and without the drama."

So, to all machinists tired of fighting a losing battle: The revolution is here. And it comes in three flavors: 300-M for finesse, 400-M for versatility, 500-M for brute force. Ready to let your lathe breathe easy? The future of stainless steel threading isn’t just better—it’s unstoppable.

Try MRMN inserts today and see why machinists are calling them ‘the last threading tool you’ll ever need.’

![]()