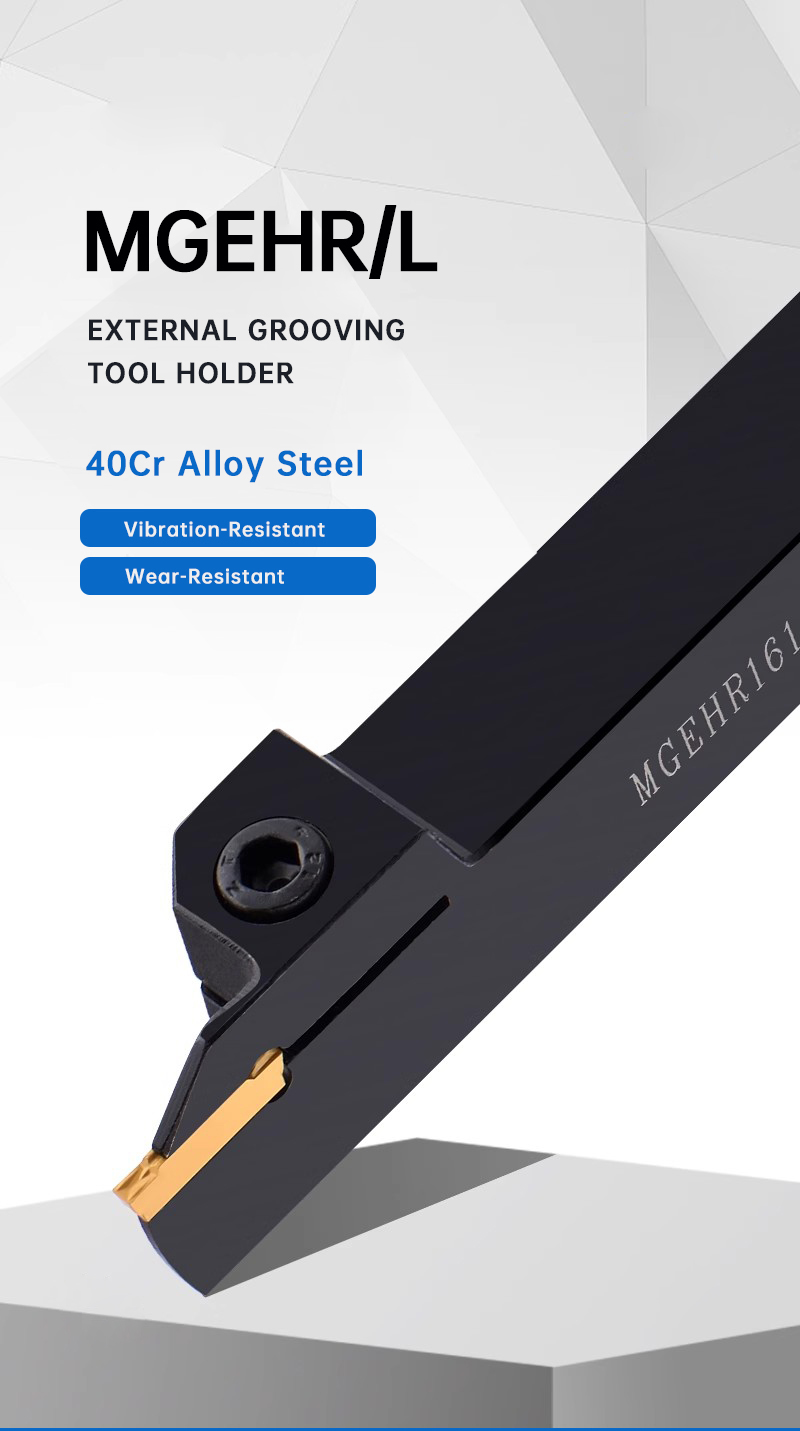

The MGEHR/L series external grooving tools are engineered for precision CNC machining, integrating advanced material science and optimized design to meet rigorous industrial demands. Constructed with ultra-fine grain carbide substrates (WC-Co alloy with 94%+ tungsten carbide content), the tools exhibit exceptional wear resistance and transverse rupture strength (≥3200MPa), ensuring durability even in continuous cutting of high-hardness materials (up to HRC 45).

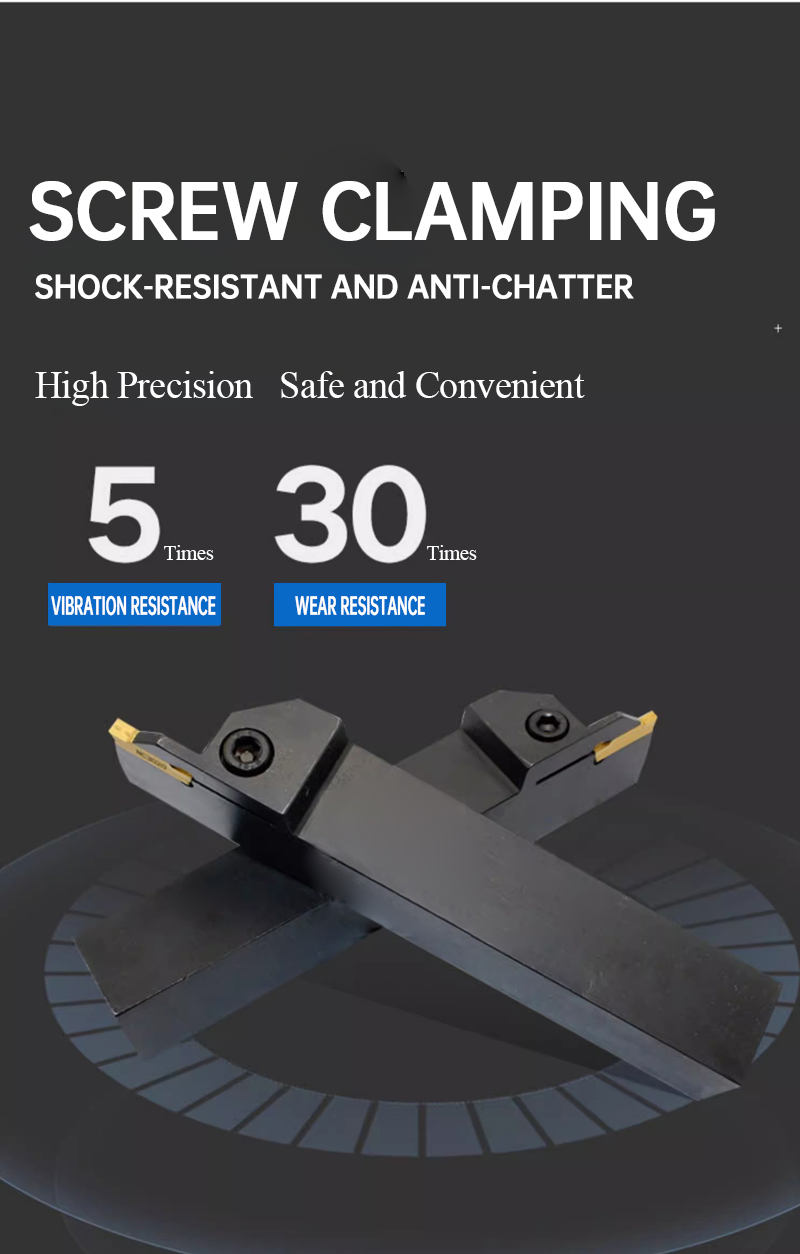

The cutting edges undergo multi-stage precision grinding: initial coarse grinding shapes the contour, followed by fine grinding to achieve Ra≤0.2μm surface finish, and final honing for a micro-arc edge (0.01-0.03mm radius) that reduces cutting force by 15% and prevents edge chipping. The optimized chip breaker geometry—featuring a 12° rake angle and curved chip pocket—enables efficient chip evacuation across material types, from low-carbon steel to duplex stainless steel, avoiding workpiece scratches and machining interruptions.

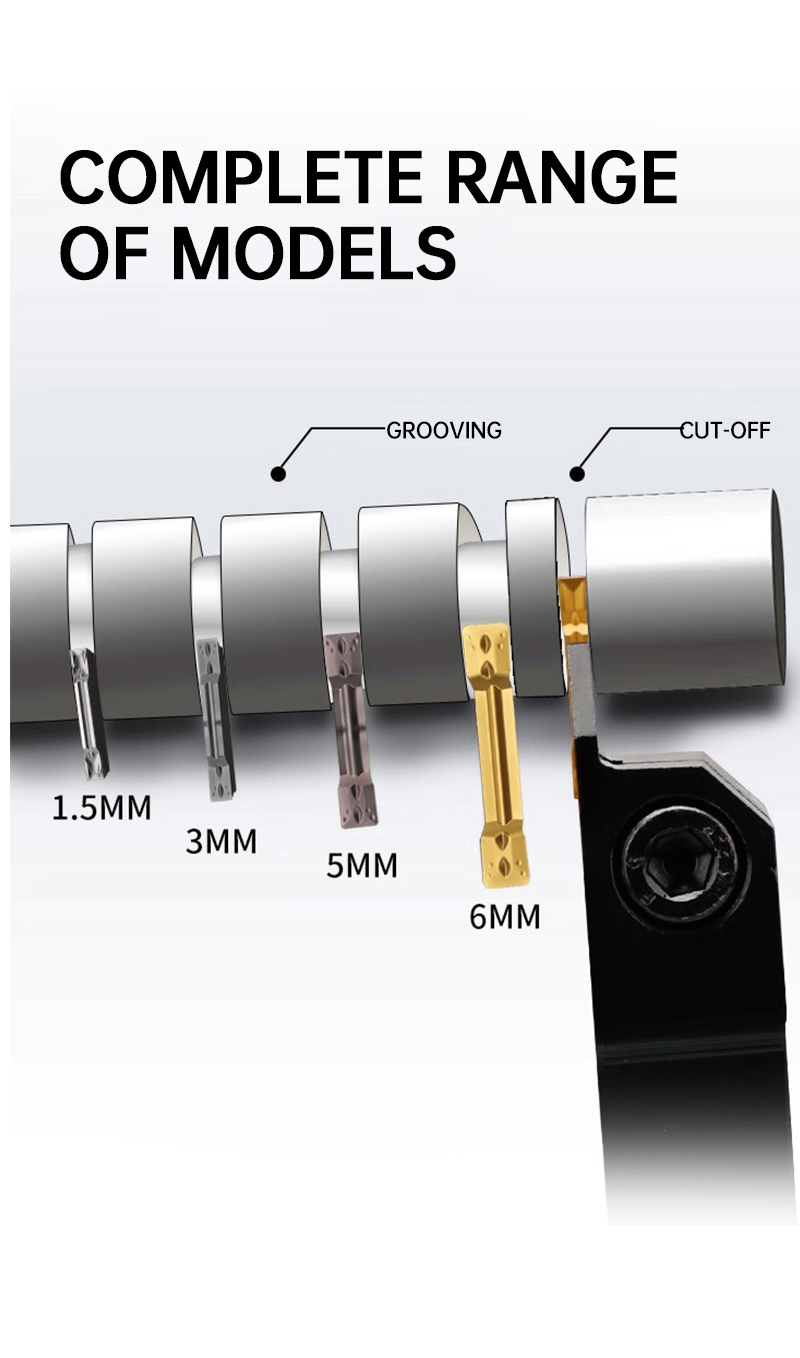

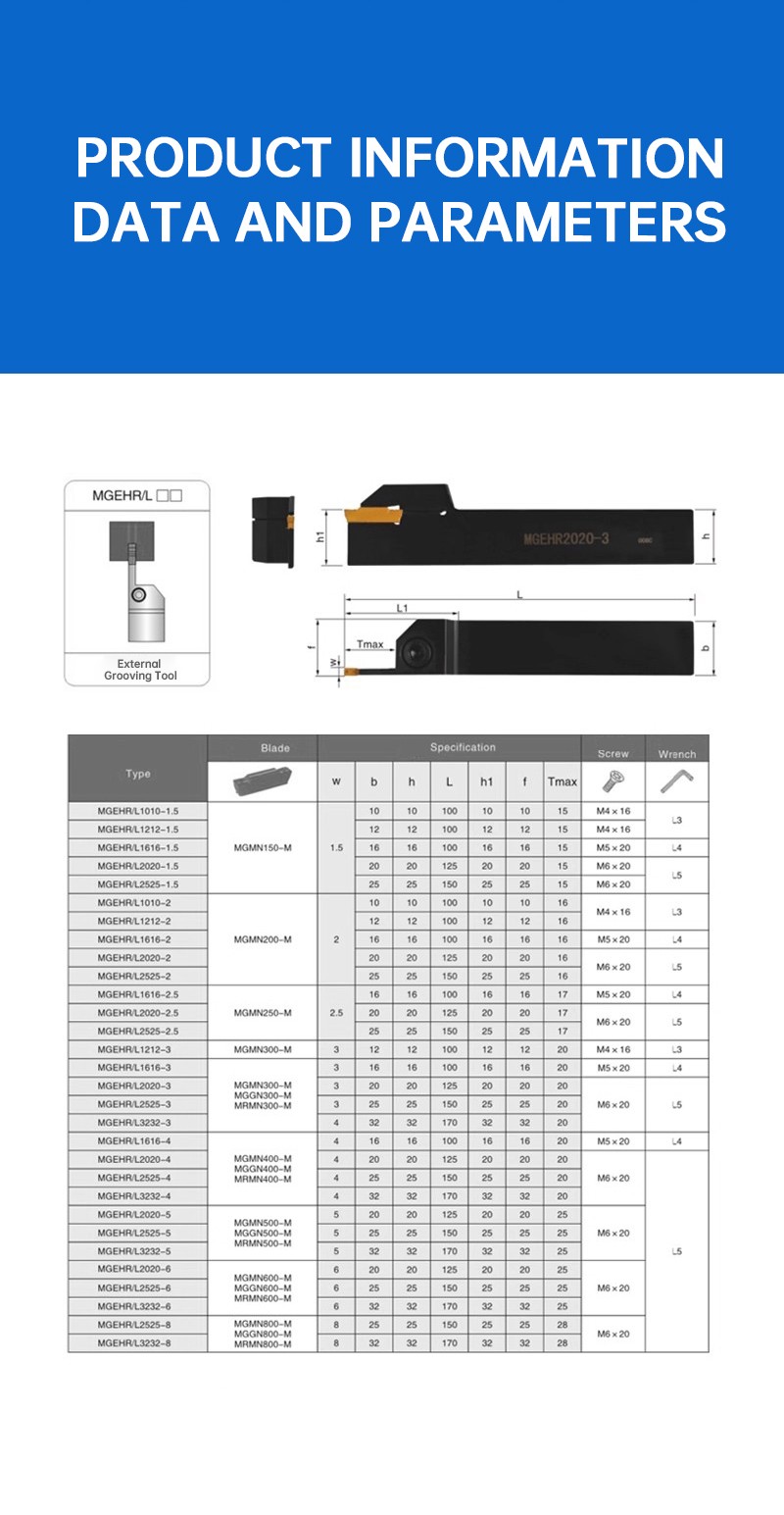

With a broad applicability, the series covers groove widths from 1mm to 10mm and depths up to 15mm, compatible with all mainstream CNC lathes (e.g., Haas, DMG MORI, Mazak) via standard shank interfaces (square shank 10×10mm to 25×25mm). Each tool undergoes 100% post-production inspection: dimensional tolerance (±0.005mm) verified by CMM, and cutting performance validated through 50-hour continuous machining tests. Backed by a 12-month warranty and technical support team, it is a reliable solution for automotive axle machining, mold cavity grooving, and precision hydraulic component manufacturing.

![1759020114867249.jpg]()

![1759020114169776.jpg]()

![1759020114771129.jpg]()

![1759020114559586.jpg]()

![1759020115745556.jpg]()

![1759020115835782.jpg]()

![1759020115264849.jpg]()