Carbide Internal Grooving Tool Holder for CNC Lathe - High Precision Machining, 10mm Shank, Heavy Duty Design | IRON ROOT

Structural design advantages

1. Modular rapid tool change system

Supports the replacement of blades and tool bars in seconds, compatible with ISO 13399/DIN 4984 industrial standards, and adapts to mainstream CNC machine tool interfaces such as Mazak and DMG.

2. Multi-dimensional cutting direction compatibility

The integrated design of left/right cutting direction covers the needs of inner hole grooves, end face grooves and complex contour processing, reducing the frequency of tool replacement.

Process performance advantages

1. High-pressure internal cooling channel technology

Integrated ≥70Bar high-pressure coolant channel, effectively reducing cutting temperature by 30%, reducing tool thermal deformation and improving surface finish.

2. Superhard composite coating treatment

Optional coating processes such as TiAlN and DLC, the friction coefficient is reduced to 0.15-0.25, and the tool life is extended by 2-3 times.

Industrial adaptation advantages

1. Precision parameterized customization capabilities

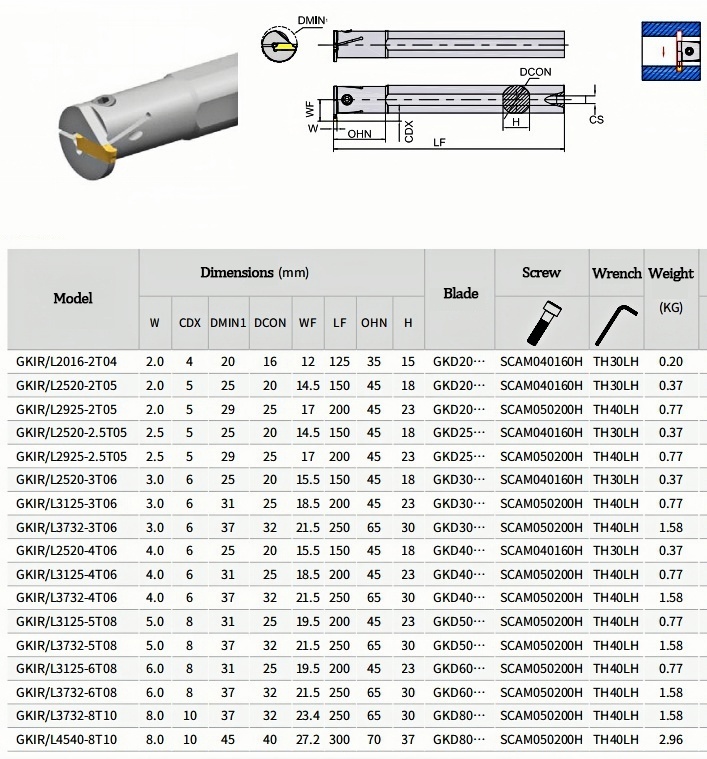

Supports non-standard tool holder size (8-25mm), blade groove (0.4-3mm) and special coating customization to meet aerospace-grade tolerance requirements (±0.005mm).

2. Dual certification reliability guarantee

Passed ISO 9001 quality system and IATF 16949 automotive industry certification to ensure batch processing stability and traceability.

Cost control advantage

1. Universal compatible blade design

Adaptable to 6 mainstream blade models such as TPMT and CCMT to reduce user inventory management costs.

2. Heavy-duty structure vibration optimization

Adopting box-section tool bar design, rigidity is increased by 40%, and processing accuracy can still be maintained under intermittent cutting conditions.

As the core process equipment in the field of CNC machining, the internal groove turning tool holder adopts a modular rapid tool change system design, which realizes the switching of the tool bar and the blade in seconds through a standardized interface. The box-section tool body structure combined with high-rigidity alloy materials can maintain a radial runout accuracy of less than 0.005mm under heavy cutting conditions, which is especially suitable for high-precision internal hole groove machining in the aerospace field. The front end of the tool holder is integrated with a multi-directional coolant channel, which supports high-pressure coolant injection above 70Bar, effectively controlling the cutting temperature and improving chip removal efficiency.

The main material is ultra-fine-grained cemented carbide, and the tungsten carbide particles are densely combined with the cobalt-based binder phase through hot isostatic pressing technology. The hardness can reach above HRA93.5, and the wear resistance is 3 times higher than that of traditional high-speed steel. The blade contact surface is plated with a multi-layer composite coating using physical vapor deposition (PVD) technology, in which the friction coefficient of the TiAlN coating is reduced to 0.18, and it can still maintain stable chemical inertness during high-temperature cutting, which is particularly suitable for continuous cutting of difficult-to-process materials such as stainless steel and nickel-based alloys.