BAP400R CNC Milling Tool Holder

1.CNC tool holder is hardened and quenched to make milling easier.

2.BAP400R CNC milling tool holder fits tightly to reduce wear.

3.Milling tool holder effectively avoids air and prevents friction.

4.High-quality steel 40CrMo material.

5.BAP400R CNC milling tool holder is made of 40CrMo material, which is crack-resistant and wear-resistant, effectively suppressing the vibration of the tool holder during processing and reducing losses.

6.The CNC tool holder is vacuum quenched first and then tapped to avoid deformation. The blade is installed without gaps, effectively reducing shock and avoiding losses.

7.The screw hole position and the screw bevel of the milling tool holder form a triangular positioning so that the blade and the tool bar do not rotate during processing, ensuring that the blade does not crack during processing.

Description:

1.BAP400R CNC milling tool holder is made of 40CrMo material, which is crack-resistant and wear-resistant, effectively suppressing the vibration of the tool holder during processing and reducing losses.

2.The CNC tool holder is vacuum quenched first and then tapped to avoid deformation. The blade is installed without gaps, effectively reducing shock and avoiding losses.

3.The screw hole position and the screw bevel of the milling tool holder form a triangular positioning so that the blade and the tool bar do not rotate during processing, ensuring that the blade does not crack during processing.

Material

The BAP400R CNC milling tool holder is constructed from high-quality 40CrMo alloy steel, a material renowned for its exceptional mechanical

properties. It offers superior crack

resistance and wear resistance, making it robust enough to withstand the rigors of heavy-duty machining operations. This alloy also provides

excellent toughness, ensuring the toolholder maintains its structural integrity even under high-stress conditions.

Key Features

Enhanced Stability & Vibration Damping: The inherent properties of 40CrMo, combined with the tool holder's precision design,

effectively suppress vibration during processing.

This not only improves machining accuracy but also reduces unnecessary wear and tear on both the tool holder and the blade,

minimizing operational losses.

Precision Manufacturing: Undergoing a vacuum quenching process followed by tapping ensures the tool holder retains its shape without

deformation. This meticulous manufacturing

results in a blade installation with zero gaps, further reducing shock during cutting and preventing potential damage to both the tool

and the workpiece.

Secure Blade Locking: The triangular positioning formed by the screw hole position and the screw bevel creates a firm and stable connection

between the blade and the tool bar.

This design prevents rotation of the blade during processing, a critical feature that ensures the blade remains intact and avoids cracking,

even during high-intensity milling tasks.

Applications

The BAP400R CNC milling tool holder is versatile and well-suited for a range of milling operations, including:

Face milling of various materials such as steel, cast iron, and non-ferrous metals (aluminum, copper alloys).

Roughing and semi-finishing operations in industries like automotive manufacturing, machinery production, and mold making.

Creating flat surfaces, shoulders, and grooves with high precision, meeting the strict tolerances required in precision engineering.

Compatible Machines

This tool holder is specifically designed for use with CNC milling machines, including:

Vertical machining centers (VMCs) equipped with standard tool change systems.

Horizontal machining centers (HMCs) for more complex multi-sided milling tasks.

High-speed CNC milling machines, where its vibration-damping properties are particularly beneficial for maintaining accuracy at high spindle speeds.

Lifespan

With proper maintenance and use within recommended parameters, the BAP400R CNC milling tool holder boasts an impressive lifespan.

The 40CrMo material, when combined with the

anti-deformation and wear-resistant features, allows it to endure thousands of machining cycles. Typically, it can last 2-3 times longer than

standard tool holders made from lower-grade

materials, reducing the frequency of replacements and lowering long-term operational costs. The blade, when protected by the tool holder's

stable design, also experiences extended

life due to reduced shock and vibration-related damage.

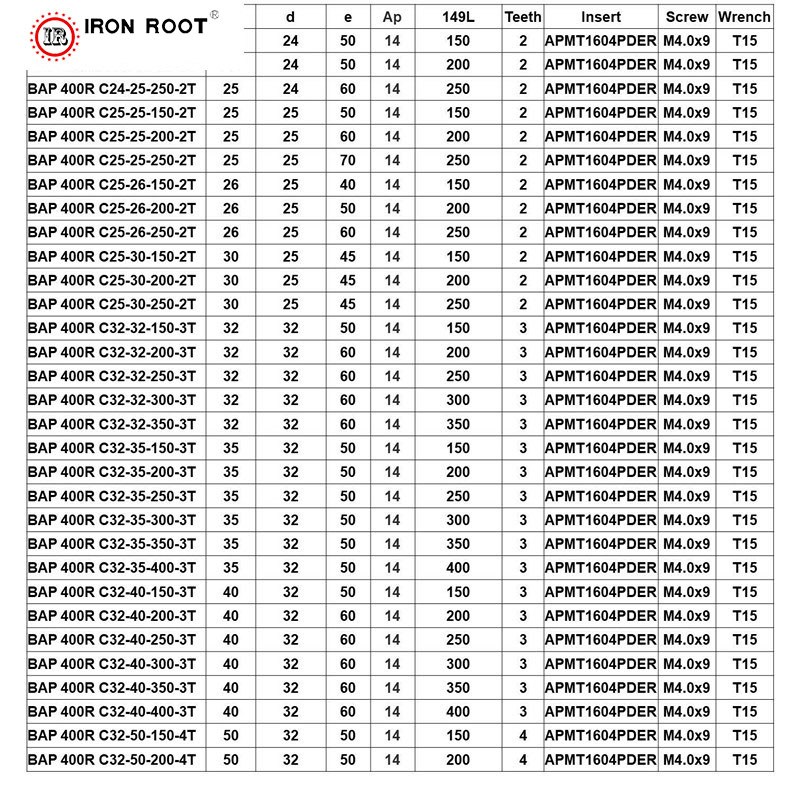

Specifications:

| Product Name | BAP400R CNC Milling Tool Holder | ||||

| Material | 40CrMo steel | ||||

| Model | BAP400R | ||||

| Number of inserts | 2T, 3T | ||||

| Suitable processing | Rough processing, fine processing, excavation processing, grooving processing, plane profiling processing, etc. | ||||

| BAP400R CNC Milling Tool Holder Models | |||

| BAP400R-24 2TC20-160L | BAP400R-25 2TC25-300L | BAP400R 30 2TC20-150L | BAP400R 35 3TC32-160L |

| BAP400R-25 2TC20-160L | BAP400R-25 2TC25-350L | BAP400R 30 2TC20-200L | BAP400R 35 3TC32-200L |

| BAP400R-25 2TC20-200L | BAP400R-26 2TC25-120L | BAP400R 32 3TC25-160L | BAP400R 35 3TC32-250L |

| BAP400R-25 2TC20-250L | BAP400R-26 2TC25-160L | BAP400R 32 3TC25-200L | BAP400R 35 3TC32-300L |

| BAP400R-25 2TC24-120L | BAP400R-26 2TC25-200L | BAP400R 32 3TC25-250L | BAP400R 35 3TC32-350L |

| BAP400R-25 2TC24-160L | BAP400R-26 2TC25-250L | BAP400R 32 3TC25-300L | BAP400R 35 3TC32-400L |

| BAP400R-25 2TC24-200L | BAP400R-26 2TC25-300L | BAP400R 32 3TC32-160L | BAP400R 40 3TC32-160L |

| BAP400R-25 2TC24-250L | BAP400R-26 2TC25-350L | BAP400R 32 3TC32-200L | BAP400R 40 3TC32-200L |

| BAP400R-25 2TC24-300L | BAP400R-28 2TC25-160L | BAP400R 32 3TC32-250L | BAP400R 40 3TC32-250L |

| BAP400R-25 2TC24-350L | BAP400R 30 2TC25-160L | BAP400R 32 3TC32-300L | BAP400R 40 3TC32-300L |

| BAP400R-25 2TC25-120L | BAP400R 30 2TC25-200L | BAP400R 32 3TC32-350L | BAP400R 40 3TC32-350L |

| BAP400R-25 2TC25-160L | BAP400R 30 2TC25-250L | BAP400R 32 3TC32-400L | BAP400R 40 3TC32-400L |

| BAP400R-25 2TC25-200L | BAP400R 30 2TC25-300L | BAP400R 32 3TC32-450L | |

| BAP400R-25 2TC25-250L | BAP400R 30 2TC20-120L | ||

Ordering Information:

For accurate pricing and delivery details for our BAP400R CNC Milling Tool Holder, please reach out to our sales team. We also provide tailored solutions to fit your

unique project needs. Let us help you find the perfect match for your requirements.