MIR Series Anti-Vibration CNC Boring Tool For Small Internal Holes - Tungsten Steel High Precision

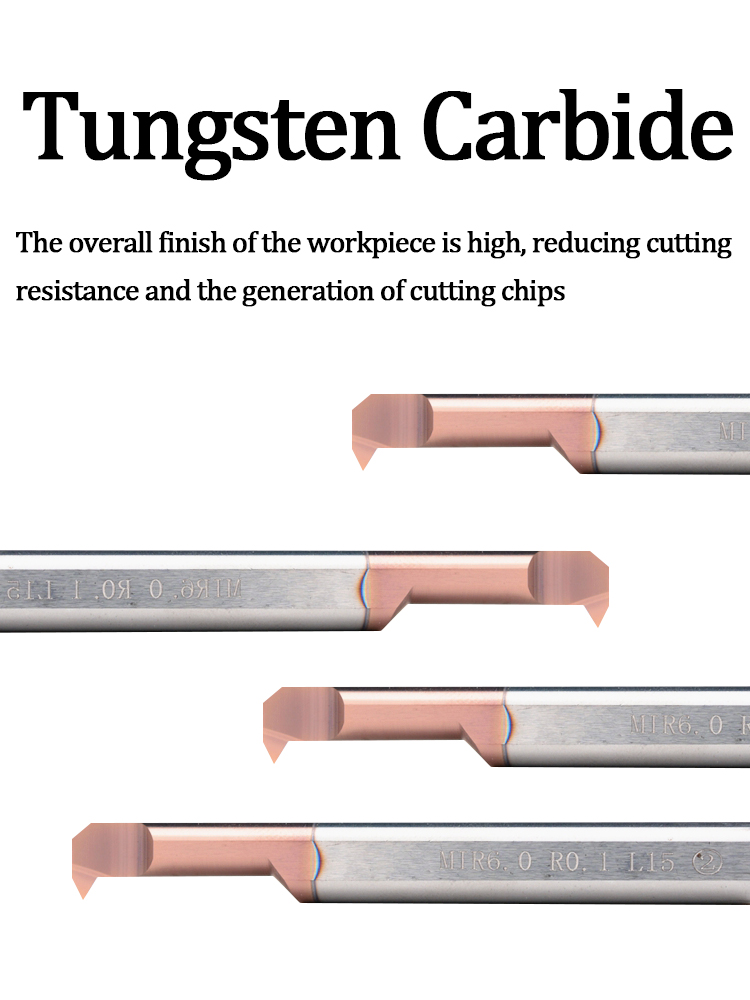

1. High-strength tungsten steel material, outstanding wear resistance and life

Made of alloy CNC tungsten steel, with a hardness of more than HRC90, high temperature resistance and impact resistance, especially suitable for processing hard materials such as stainless steel and titanium alloy156.

Surface coating treatment further extends the service life, which is 30%-50% higher than the life of ordinary tools79.

2. Anti-seismic design ensures processing stability

The tool bar has a built-in anti-seismic damping structure to effectively reduce processing vibration and achieve a high precision of ±0.005mm, which is particularly suitable for deep holes and parts with large aspect ratio68.

In an actual case, after a certain automotive parts company used it, the processing error of the engine cylinder was reduced by 60%6.

3. Precision processing capabilities cover micro-apertures

Supports 0.5mm-6mm micro-aperture processing, with a minimum processing diameter of 0.5mm, meeting the ultra-fine needs of precision instruments, electronic components, etc.13. Provide customized specifications (such as adjustable length of 100mm-300mm), adapt to different depths and complex structure processing scenarios39.

4. Multi-field adaptability and efficient heat dissipation

Widely used in aerospace, medical equipment, automobile manufacturing and other fields, especially suitable for sterile environments and high-precision scenarios369.

Built-in coolant channel quickly dissipates heat to avoid tool overheating and deformation, ensuring continuous processing stability69.

Summary: MIR small hole boring tool has become the preferred tool for difficult processing tasks through material innovation, anti-seismic technology, precision technology and scenario adaptability.

The MIR series of small hole boring tools are tools designed for high-precision micro-aperture processing. They integrate the three core advantages of tungsten steel alloy material, anti-vibration technology and customized services, and are widely used in aerospace, medical equipment, electronic components and other fields that require strict processing accuracy. Its diameter covers the range of 0.5mm-6mm, supports 100mm-300mm adjustable length, and is suitable for special scenarios such as deep holes and complex structures, becoming a benchmark tool for modern industrial precision processing.

| D | MIR | L | L1 | mm/Pitch | Minimum aperture |

| 3 | D3-MIR 3 A55 L15 | 50 | 15 | 0.5-1.0 | 3.2 |

| D3-MIR 1.4 A60 L4 | 50 | 4 | 0.3-0.4 | 1.5 | |

| D3-MIR 1.9 A60 L6 | 50 | 6 | 0.3-0.5 | 2 | |

| D3-MIR 2.4 A60 L7 | 50 | 7 | 0.3-0.6 | 2.5 | |

| D3-MIR 3.0 A60 L10 | 50 | 10 | 0.5-0.8 | 3.2 | |

| D3-MIR 3.0 A60 L15 | 50 | 15 | 0.8-1.0 | 3.2 | |

| 4 | D4-MIR 1.4 A60 L4 | 50 | 4 | 0.3-0.4 | 1.5 |

| D4-MIR 1.9 A60 L6 | 50 | 6 | 0.3-0.5 | 2 | |

| D4-MIR 2.4 A60 L7 | 50 | 7 | 0.3-0.6 | 2.5 | |

| D4-MIR 3.0 A60 L10 | 50 | 10 | 0.5-0.8 | 3.2 | |

| D4-MIR 3.0 A60 L15 | 50 | 15 | 0.8-1.0 | 3.2 | |

| D4-MIR 4.0 A60 L10 | 50 | 10 | 0.5-1.0 | 4.1 | |

| D4-MIR 4.0 A60 L12 | 50 | 12 | 0.5-1.0 | 4.1 | |

| D4-MIR 4.0 A60 L15 | 50 | 15 | 0.8-1.0 | 4.1 | |

| D4-MIR 4 A55 L15 | 50 | 15 | 0.5-1.0 | 4.1 | |

| 5 | D5-MIR 5 A55 L15 | 50 | 15 | 0.5-1.25 | 5.1 |

| D5-MIR 5 A55 L22 | 50 | 22 | 0.5-1.25 | 5.1 | |

| D5-MIR 5 A60 L15 | 50 | 15 | 1.0-1.25 | 5.1 | |

| D5-MIR 5 A60 L22 | 50 | 22 | 1.0-1.25 | 5.1 | |

| 6 | D6-MIR 5 A55 L15 | 50 | 15 | 0.5-1.25 | 5.1 |

| D6-MIR 5 A55 L22 | 50 | 22 | 0.5-1.25 | 5.1 | |

| D6-MIR 5 A60 L15 | 50 | 15 | 1.0-1.25 | 5.1 | |

| D6-MIR 5 A60 L22 | 50 | 22 | 1.0-1.25 | 5.1 | |

| D6-MIR 6 A55 L15 | 50 | 15 | 0.5-1.5 | 6.0 | |

| D6-MIR 6 A55 L22 | 50 | 22 | 0.5-1.5 | 6.0 | |

| D6-MIR 6 A60 L15 | 50 | 15 | 1.0-1.5 | 6.0 | |

| D6-MIR 6 A60 L22 | 50 | 22 | 1.0-1.5 | 6.0 | |

| 8 | D8-MIR 8 A55 L22 | 60 | 22 | 0.75-2.0 | 8.0 |

| D8-MIR 8 A55 L30 | 60 | 30 | 0.75-2.0 | 8.0 | |

| D8-MIR 8 A60 L22 | 60 | 22 | 1.0-2.0 | 8.0 | |

| D8-MIR 8 A60 L30 | 60 | 30 | 1.0-2.0 | 8.0 |

| industry | Typical Applications | Core demand matching |

| Aerospace | Engine turbine blade cooling holes, sensor micro hole processing | High hardness material processing, ultra-precision tolerance (±0.005mm) |

| Medical Devices | Internal thread processing of endoscopic catheters and orthopedic implants | Aseptic environment adaptability, burr-free surface finish |

| Electronic components | Micro-holes in semiconductor chip carriers and precision inner holes in connectors | Micro-diameter processing capability (starting from 0.5mm), anti-static interference |

| Automotive | Fuel nozzle micro-hole, gearbox valve body deep hole processing | Anti-seismic performance, batch processing consistency |

The MIR series has become a well-known product in the field of precision machining with its differentiated positioning of "micro aperture + high stability". Third-party test data shows that its machining surface roughness (Ra) is ≤0.4μm, which is 20% better than similar products. In the future, with the introduction of intelligent coating technology and IoT tool monitoring system, the MIR series is expected to further achieve adaptive optimization of machining parameters and promote precision machining into the era of intelligence.