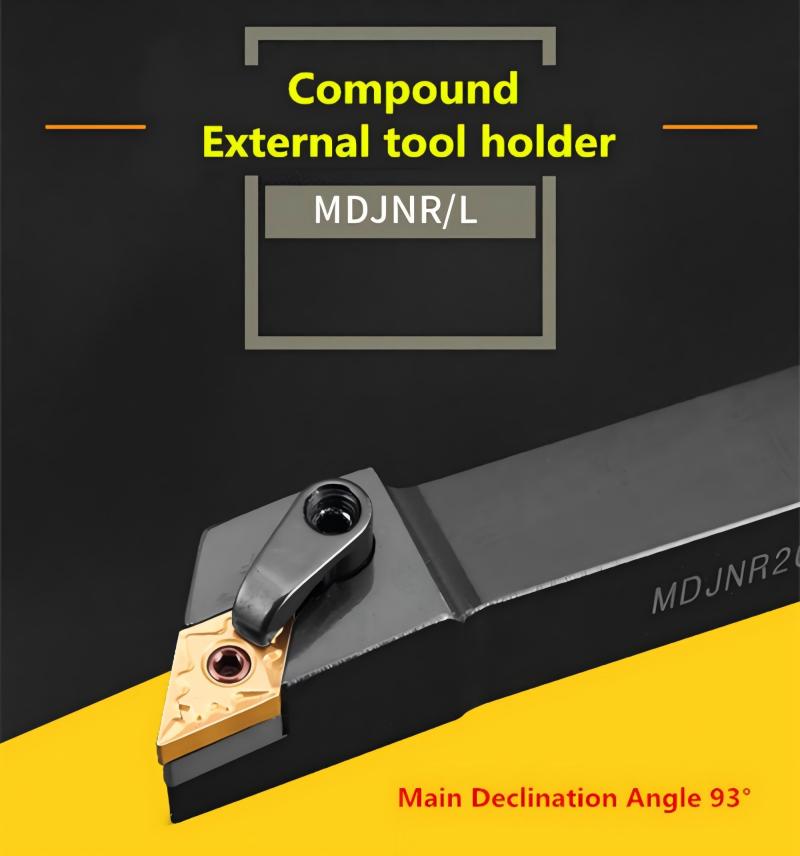

MDJNR External Turning Tool Holder

MDJNR/L CNC Lathe Tool Holder Key Benefits:

High Rigidity: The tool holder design offers excellent rigidity

Compatibility: It is compatible with a wide range of carbide inserts

Quick Changeover: The MDJNR/L facilitates quick tool changes

Durability: Made from premium materials, this tool holder is built to last

Cost-Effective: It is designed to minimize tool costs by reducing the frequency of replacement and maintenance.

Reduce Vibration: The tool holder design helps minimize vibration

Easy Maintenance: The MDJNR/L is easy to maintain, ensuring it stays in top condition for a long time.

These features make the MDJNR/L an excellent choice for precision machining in CNC lathe operations.

About the product

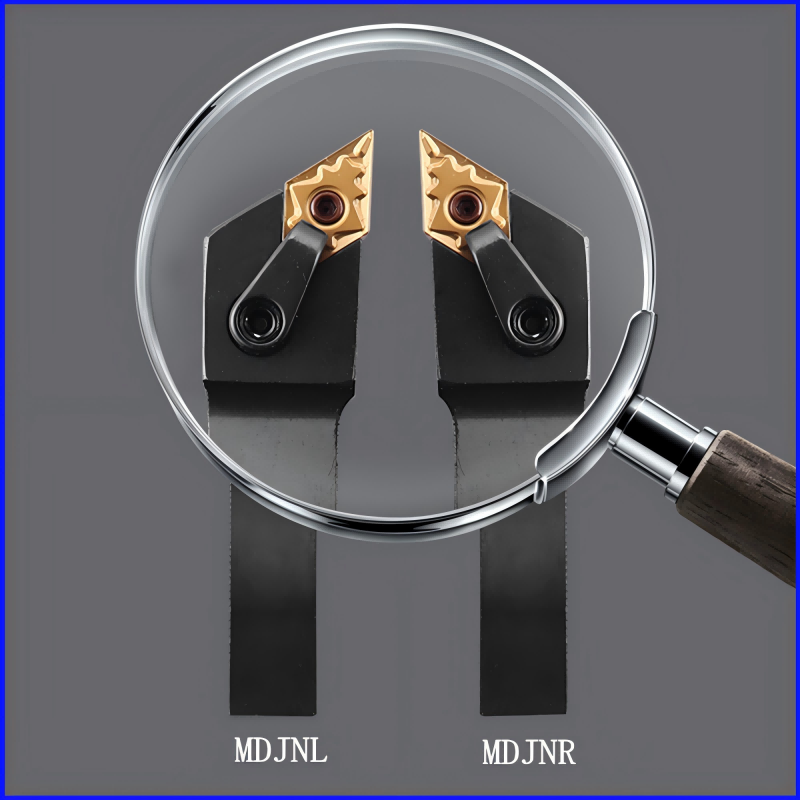

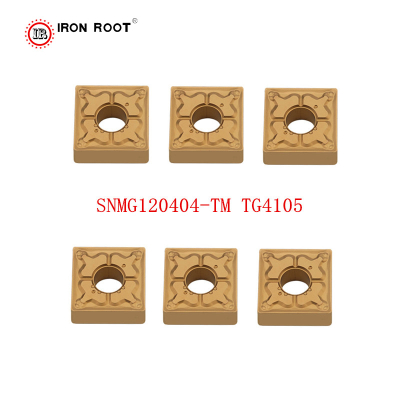

The MDJNL CNC lathe turning tool holder is a robust and versatile tool designed for efficient external turning operations. It features a clamp and

locking pin mechanism that securely holds the insert, ensuring stability during high-speed cutting. This tool holder is compatible with DNMG style

inserts and is suitable for a wide range of materials, from steel to cast iron. It offers easy indexability, reducing downtime and increasing productivity.

The MDJNL is known for its durability, precision, and ability to deliver a fine surface finish on machined parts

Overview

The MDJNL (and MDJNR/L variant) CNC lathe turning tool holder is engineered for precision and efficiency in external turning operations. Combining robust construction, advanced clamping technology, and user-centric design, it stands out as a reliable solution for high-performance CNC machining, balancing durability, productivity, and cost-effectiveness.

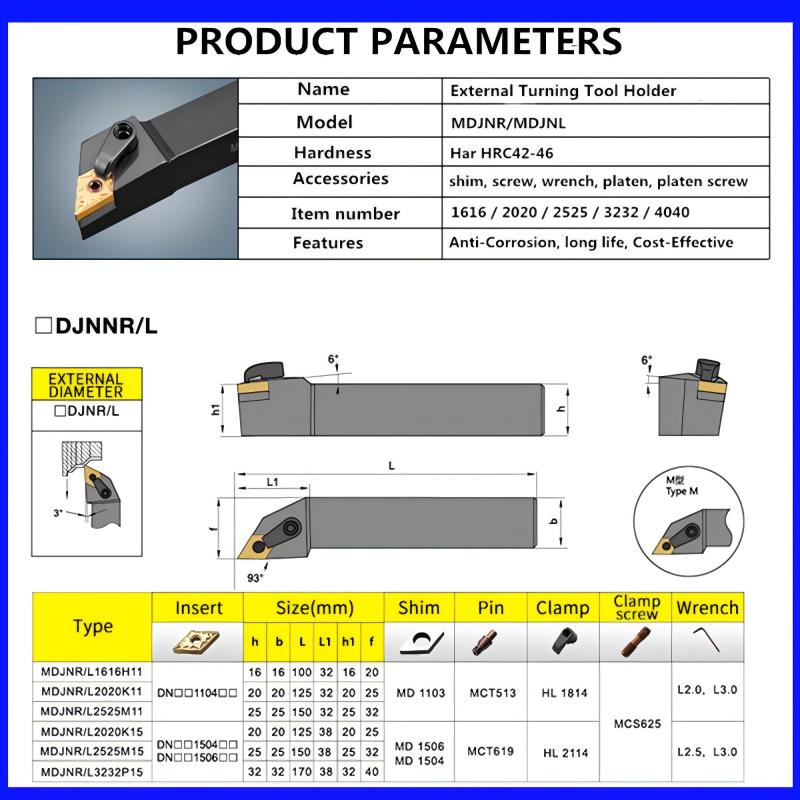

Application | Model Name | External Turning Tool Holder | ||

Material | Alloy steel | Model Number | MDJNR/L | |

For insert | DNMG | Brand | ||

Use | Turning, Profiling | Origin | Mainland China | |

Color | Black | Material | 40CrMo-42CrMo | |

Features | anti-corrosion,long life,cost-effective |

Material & Construction

2. Secure Insert Clamping

3. Broad Compatibility

4. Quick Changeover & Indexability

5. Vibration Reduction

6. Durability & Longevity

7. Cost-Effectiveness

8. Easy Maintenance

Compatible Machines & Applications

Summary

About Our Company

Welcome to inquire about the prices, and we will provide you with the best service.