MQR Micro Boring Tools Tungsten Carbide Boring Tools

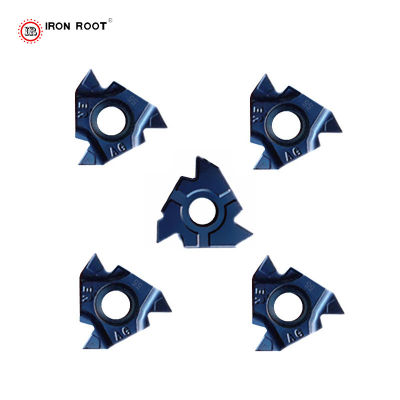

1.Crafted from ultra-fine particle tungsten steel for exceptional hardness and toughness

2.Equipped with imported nano-coating for superior heat resistance and oxidation resistance

3.Delivers precise machining performance even for tiny apertures

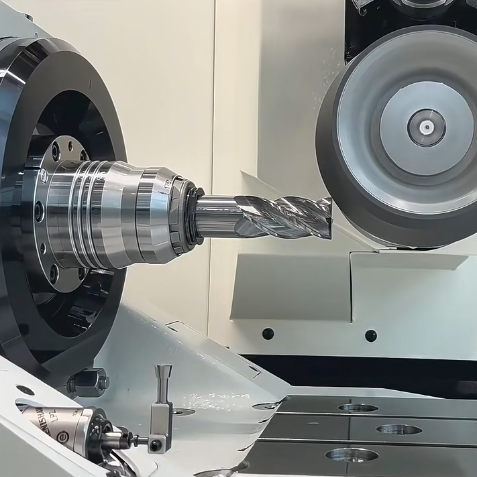

4.Maintains stability during high-speed cutting operations

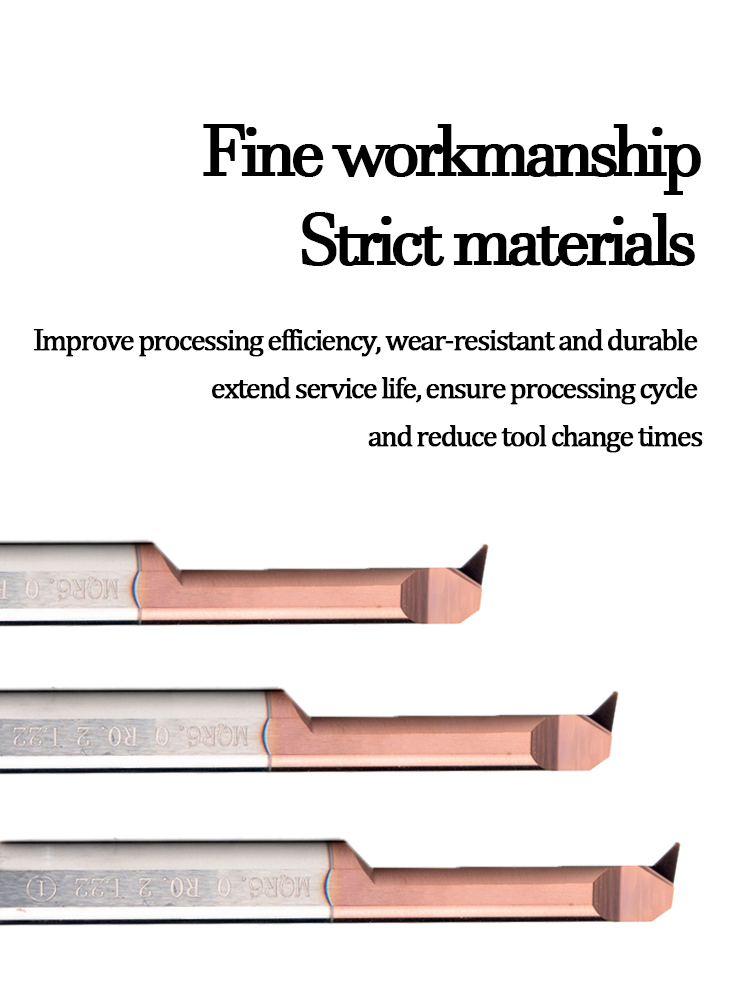

5.Extended service life compared to standard small hole boring tools

6.Compatible with various precision CNC machines and machining centers

7.Ideal for high-precision industries requiring micro-aperture processing

About the product

In the field of precision machining, the machining accuracy and quality of tiny apertures have always been a challenge faced by many machining companies. The MQR series of small hole boring cutters have become the leaders in this field with their excellent performance and precision machining capabilities.The MQR series of small hole boring cutters are made of high-quality tungsten steel alloy (ultra-fine particle tungsten steel), which gives the tool high hardness, high wear resistance, good impact resistance and toughness. The knife is also covered with imported nano-coating, which makes it excellent in heat resistance and oxidation resistance, stable cutting performance, and can maintain excellent performance during high-speed cutting, effectively extending the service life of the tool.

The MQR series small hole boring cutters represent the pinnacle of precision machining tools, engineered specifically to address the challenges of micro-aperture processing. These cutters deliver exceptional dimensional accuracy and surface finish, even when working with the smallest hole diameters. Their rigid construction minimizes vibration during operation, ensuring consistent performance across extended machining cycles. The tool design incorporates advanced geometry optimized for small hole applications, featuring precise cutting edges that reduce material deformation and improve chip evacuation.

Materials & Construction

Crafted from premium tungsten steel alloy with ultra-fine particles, the MQR series boasts an exceptional combination of high hardness and superior toughness. This material selection provides the with remarkable wear resistance while maintaining sufficient impact resistance to handle varying machining conditions. The substrate is further enhanced with an imported nano-coating that significantly boosts heat resistance and oxidation properties—critical factors in maintaining cutting stability during high-speed operations.

The MQR series of small hole boring cutters have various specifications, including SBQR3, SBQR4, SBQR5, SBQR6 and other models, which are suitable for internal hole turning operations of different diameters, with the minimum hole diameter ranging from 3.1 mm to 8.1 mm. Whether it is the processing of tiny precision parts or the processing of small holes in complex mechanical structures, the MQR series can easily cope with it, providing flexible and accurate solutions for processing personnel.

Its unique geometry and edge processing technology ensure efficient cutting performance and shorten processing time. The optimized tool bar structure and material effectively reduce vibration and ensure the stability of the processing process. Even at high-speed cutting, it can maintain good processing accuracy and surface quality.

| D | MQR Series | L | L1 | R | Minimum aperture |

| 3 | D3-MQR 3 R0.05 L10 | 50 | 10 | 0.05 | 3.1 |

| D3-MQR 3 R0.1 L10 | 50 | 10 | 0.1 | 3.1 | |

| D3-MQR 3 R0.15 L10 | 50 | 10 | 0.15 | 3.1 | |

| 4 | D4-MQR 3 R0.05 L10 | 50 | 10 | 0.05 | 3.1 |

| D4-MQR 3 R0.1 L10 | 50 | 10 | 0.1 | 3.1 | |

| D4-MQR 3 R0.15 L10 | 50 | 10 | 0.15 | 3.1 | |

| D4-MQR 4 R0.05 L10 | 50 | 10 | 0.05 | 4.1 | |

| D4-MQR 4 R0.1 L10 | 50 | 10 | 0.1 | 4.1 | |

| D4-MQR 4 R0.1 L15 | 50 | 15 | 0.1 | 4.1 | |

| D4-MQR 4 R0.15 L15 | 50 | 15 | 0.15 | 4.1 | |

| D4-MQR 4 R0.2 L10 | 50 | 10 | 0.2 | 4.1 | |

| D4-MQR 4 R0.2 L15 | 50 | 15 | 0.2 | 4.1 | |

| D4-MQR 4 R0.15 L22 | 50 | 22 | 0.15 | 4.1 | |

| 5 | D5-MQR 5 R0.05 L15 | 50 | 15 | 0.05 | 5.1 |

| D5-MQR 5 R0.1 L15 | 50 | 15 | 0.1 | 5.1 | |

| D5-MQR 5 R0.1 L22 | 50 | 22 | 0.1 | 5.1 | |

| D5-MQR 5 R0.2 L15 | 50 | 15 | 0.2 | 5.1 | |

| D5-MQR 5 R0.2 L22 | 50 | 22 | 0.2 | 5.1 | |

| 6 | D6-MQR 5 R0.05 L15 | 50 | 15 | 0.05 | 5.1 |

| D6-MQR 5 R0.1 L15 | 50 | 15 | 0.1 | 5.1 | |

| D6-MQR 5 R0.1 L22 | 50 | 22 | 0.1 | 5.1 | |

| D6-MQR 5 R0.2 L15 | 50 | 15 | 0.2 | 5.1 | |

| D6-MQR 5 R0.2 L22 | 50 | 22 | 0.2 | 5.1 | |

| D6-MQR 6 R0.1 L15 | 50 | 15 | 0.1 | 6.1 | |

| D6-MQR 6 R0.1 L22 | 50 | 22 | 0.1 | 6.1 | |

| D6-MQR 6 R0.2 L15 | 50 | 15 | 0.2 | 6.1 | |

| D6-MQR 6 R0.2 L22 | 50 | 22 | 0.2 | 6.1 | |

| D6-MQR 6 R0.2 L30 | 50 | 30 | 0.2 | 6.1 | |

| D6-MQR 6 R0.4 L22 | 50 | 22 | 0.4 | 6.1 | |

| 8 | D8-MQR 8 R0.15 L22 | 60 | 22 | 0.1 | 8.1 |

| D8-MQR 8 R0.2 L22 | 60 | 22 | 0.2 | 8.1 | |

| D8-MQR 8 R0.2 L27 | 60 | 27 | 0.2 | 8.1 | |

| D8-MQR 8 R0.2 L30 | 60 | 30 | 0.2 | 8.1 | |

| D8-MQR 8 R0.4 L27 | 60 | 27 | 0.4 | 8.1 |

Coating Advantages

The advanced nano-coating technology offers multiple benefits:

1.Superior heat dissipation, protecting the tool from thermal damage

Applications & Usage Areas

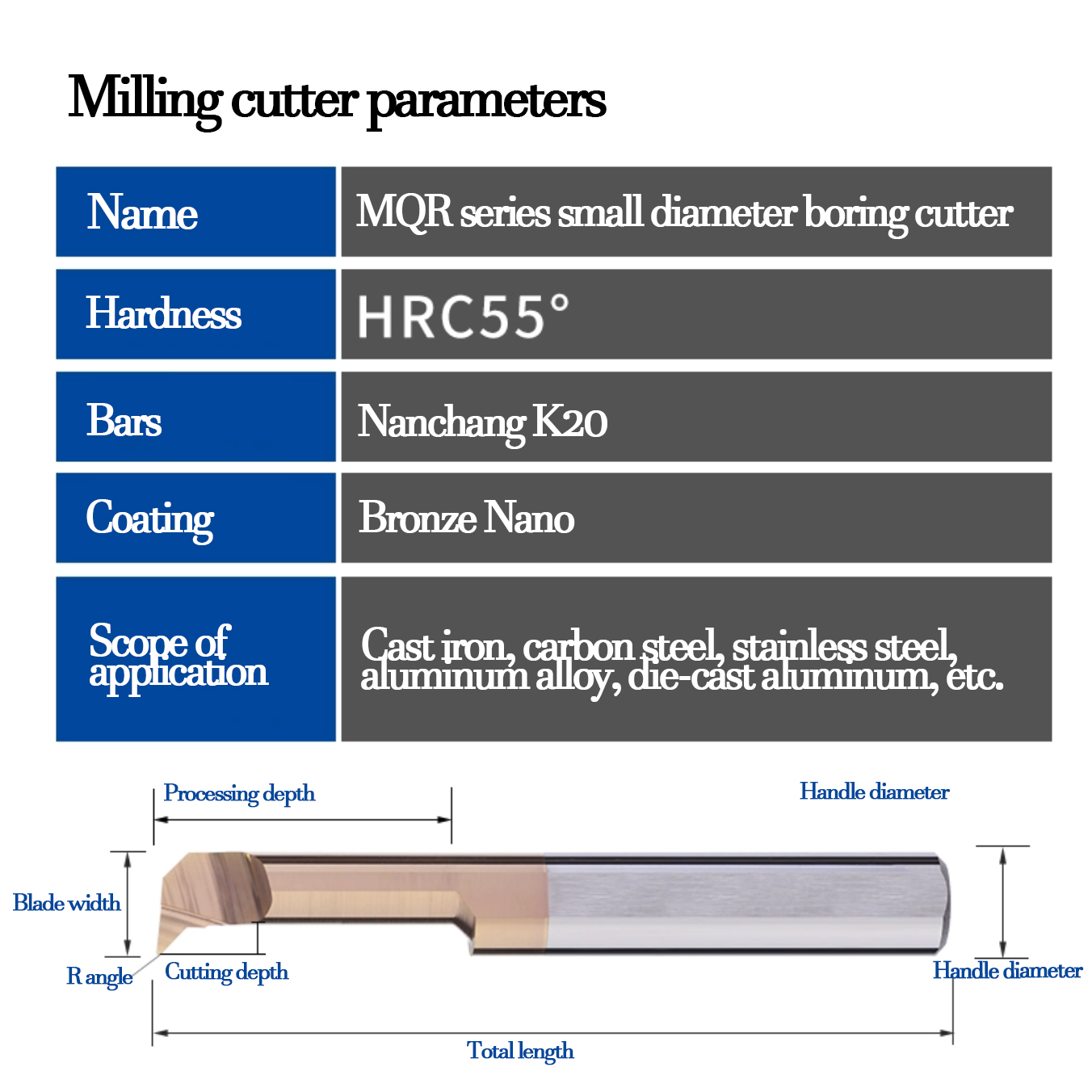

| Name | MQR series small diameter boring cutter |

| Hardness | HRC55° |

| Bars | Nanchang K20 |

| Coating | Bronze Nano |

| Scope of apphcation | Cast iron,carbon steel,stainless steel,aluminum alloy,die-cástaluminum,etc. |

The design of the MQR series small hole boring cutter fully considers the convenience of installation and adjustment, and even beginners can quickly get started. It performs well in actual use, and many professionals have given it high praise, believing that it has high precision, long life, and is easy to maintain.

In short, the MQR series small hole boring cutter has become the preferred tool for many processing companies with its excellent performance and precise processing capabilities, bringing new breakthroughs and developments to the field of precision machining.

Performance Benefits

The MQR series small hole boring cutters stand as a solution of choice for manufacturers seeking to overcome the challenges of micro-precision machining, delivering reliability, accuracy, and efficiency in the most demanding small hole applications.

About our company

Beyond standard products, we also offer custom non-standard tool solutions to address unique production requirements, delivering tailored support for complex machining scenarios.

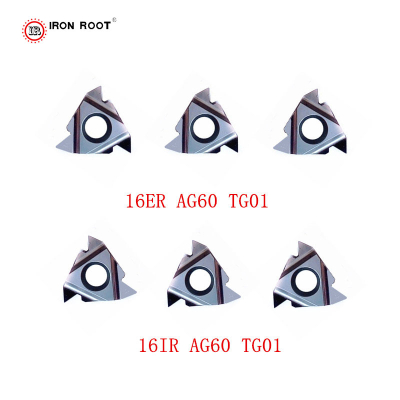

What our customers say about us

Our products are exported to numerous countries across the globe, such as the United States, the United Kingdom, Spain, Italy, Belgium, France, Germany, and more. They have gained deep love and strong support from users in these regions. All our products boast high cost-effectiveness, reliable quality assurance, and are 100% genuine.

Thank you very much for your attention.

You are welcome to inquire about the prices, and we will provide you with our best service.