Tungsten Steel 3-Edge Round Nose Milling Cutter - High Speed CNC Carbide End Mill for Metal/Woodworking - Industrial Precision Cutting Tool

1. Excellent cutting performance, suitable for complex processing scenarios

Flat-bottom blade + small R angle design: Combining the advantages of end mills and ball cutters, it can not only efficiently process flat surfaces (such as planes and sides), but also process small-angle curved surfaces, reducing cutting blind areas.

Helix angle optimization: such as 45° or 55° helix angle design, improves chip removal efficiency and reduces cutting resistance, suitable for high hardness or sticky materials such as stainless steel and aluminum alloy.

2. Wear resistance and long service life

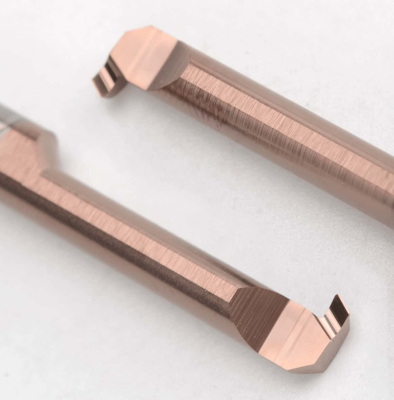

Tungsten steel material + nano coating: Using ultra-fine particle cemented carbide (such as K44, K39, etc.), combined with TS coating or TIALN nano coating technology, greatly improves wear resistance, suitable for long-term continuous processing.

No static grinding at the tip: Compared with ball cutters, round nose cutters have no static grinding at the tip during cutting, reducing local wear and extending service life.

3. High processing efficiency and stability

Integrated roughing and finishing: The tool spacing has a large adjustable range, the tool spacing is larger than that of ball cutters during roughing, the surface quality is stable during finishing, and the number of tool changes is reduced.

Anti-seismic design: Unequal tooth pitch and unequal spiral structure reduce cutting vibration, improve processing accuracy and metal removal rate.

4. Strong customization and adaptability

Non-standard parameter customization: Supports customization of parameters such as R angle, blade diameter, helix angle (such as R0.2-R2.0, extended blade design, etc.) to meet special mold or material requirements.

Multi-scenario adaptation: Covers the processing of various materials such as stainless steel, aluminum alloy, titanium alloy, graphite, etc., and is compatible with CNC, five-axis grinders and other equipment

The tool uses high-hardness tungsten steel (hard alloy) as the base material and is formed by ultra-fine particle powder metallurgy technology to ensure that the internal structure of the material is dense and uniform, with high wear resistance and impact resistance. The surface is usually covered with a nano-level coating (such as TS coating or TIALN coating), which significantly improves the anti-adhesive aluminum performance and high temperature stability, and is suitable for long-term continuous processing.

| Product name: | 3-blade aluminum round nose |

| Product material: | tungsten steel (hard alloy) |

| Number of blades: | 3 |

| Helix angle: | 55° |

| Applicable materials: | aluminum alloy/plastic/composite materials |

| Applicable machines: | CNC machining center, engraving machine and other high-speed CNC milling machines |

2. Structural design features

Blade type and helix angle optimization

The 3-edge design balances cutting efficiency and chip removal capabilities, with a sharp front angle and wide and deep chip grooves, reducing the sticking phenomenon in aluminum processing.

The helix angle is usually 55° (some models can reach 65°), and the cutting resistance is reduced by tilting the blade edge, improving cutting stability and surface finish.

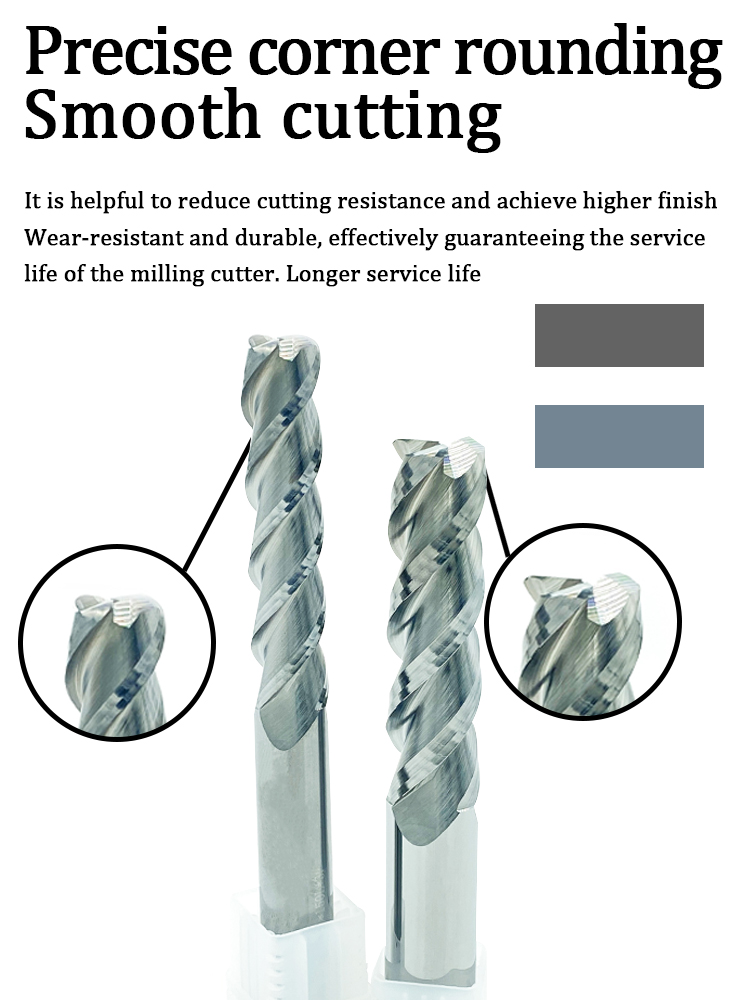

Round nose R angle design

The tip of the tool adopts a small R angle (such as R0.2-R2.0) flat bottom transition, integrating the advantages of end mills and ball cutters, which can not only efficiently process planes and side walls, but also process curved surface transition areas, reducing processing blind areas.

The R angle accuracy is controlled within ±0.02mm to ensure the geometric consistency of the processing contour.

Extended blade and shank adaptation

Standard (50-75mm) and extended (100-150mm) specifications are available to meet the needs of deep cavity processing.

Straight shank or taper shank design, compatible with mainstream equipment such as CNC machining centers and five-axis machine tools.

3. Performance advantages

Efficient cutting and wear resistance

The cutting edge geometry parameters are optimized for the low melting point and high viscosity of aluminum alloys. With the coating technology, high-speed cutting can be achieved (recommended linear speed 200-400m/min), and the single feed rate can reach 0.1-0.3mm/r.

The tool life is 2-3 times longer than that of ordinary milling cutters, and there is no built-up edge in continuous processing.

Excellent surface quality

The precision grinding process ensures that the cutting edge is burr-free. When processing aluminum alloys, the surface roughness can reach Ra0.8μm or less, which is suitable for scenes such as mobile phone shells and precision molds with high finish requirements.

Vibration prevention and stability

The unequal pitch structure and rigid cutter body design effectively suppress cutting vibration and avoid deformation or chipping of thin-walled parts.