One-Stop Shop for Milling Cutters: Complete Range for Every Application

Milling cutter advantages

Hard and durable materials: Carbide and high-hardness coatings are used to resist wear and damage, thereby extending tool life.

High precision and stability: Precision-ground cutting edges ensure precise machining dimensions and excellent surface quality.

Efficient and productive: The high-feed design enables smooth chip evacuation and shortens machining cycles.

Widely applicable: Covers a wide range of materials, including aluminum, steel, and titanium alloys, and is suitable for both rough and fine milling.

Cost-effective: Durability and low wear reduce unit machining costs.

Highly adaptable: Compatible with mainstream CNC equipment, easy to install and commission.

Chip-resistant and durable: Optimized geometry provides impact resistance and reduces the risk of chipping.

One-stop shopping

Milling cutter series

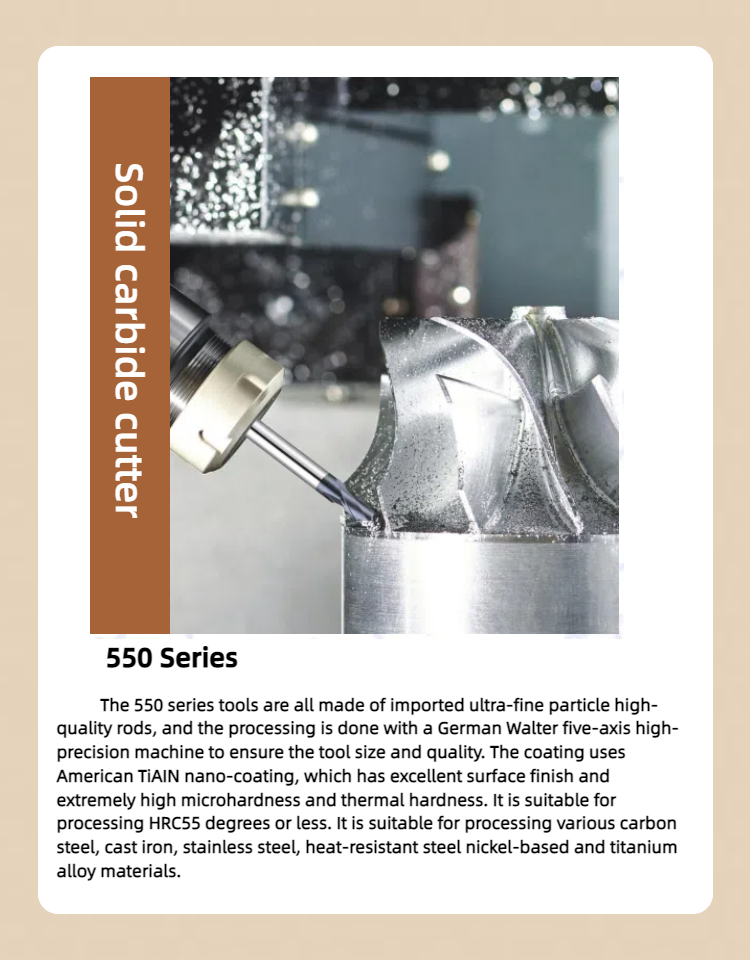

Solid carbide cutter

550 Series

The 550 series tools are all made of imported ultra-fine particle high-quality rods, and the processing is done with a German Walter five-axis high-precision machine to ensure the tool size and quality. The coating usesAmerican TiAlN nano-coating, which has excellent surface finish andextremely high microhardness and thermal hardness. it is suitable forprocessing HRC55 degrees or less. it is suitable for processing various carbonsteel, cast iron, stainless steel, heat-resistant steel nickel-based and titaniumalloy materials.

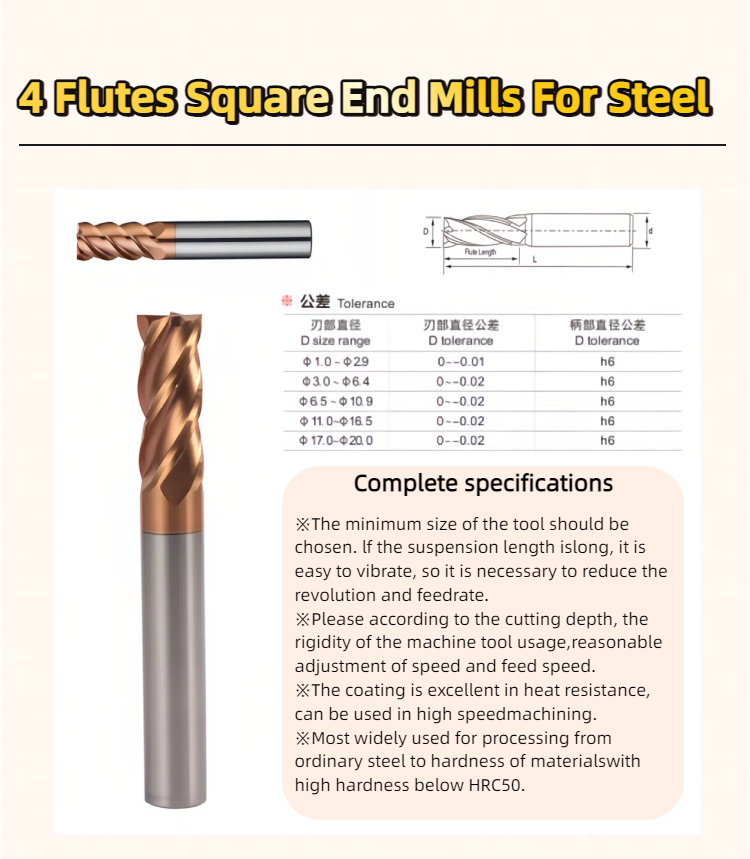

4 Flutes Square End Mills For steel

Complete specifications

※The minimum size of the tool should bechosen. lf the suspension length islong, it iseasy to vibrate, so it is necessary to reduce therevolution and feedrate.

※Please according to the cutting depth, therigidity of the machine tool usage,reasonableadjustment of speed and feed speed.

※The coating is excellent in heat resistancecan be used in high speedmachining.ЖMost widely used for processing fromordinary steel to hardness of materialswithhigh hardness below HRC50.

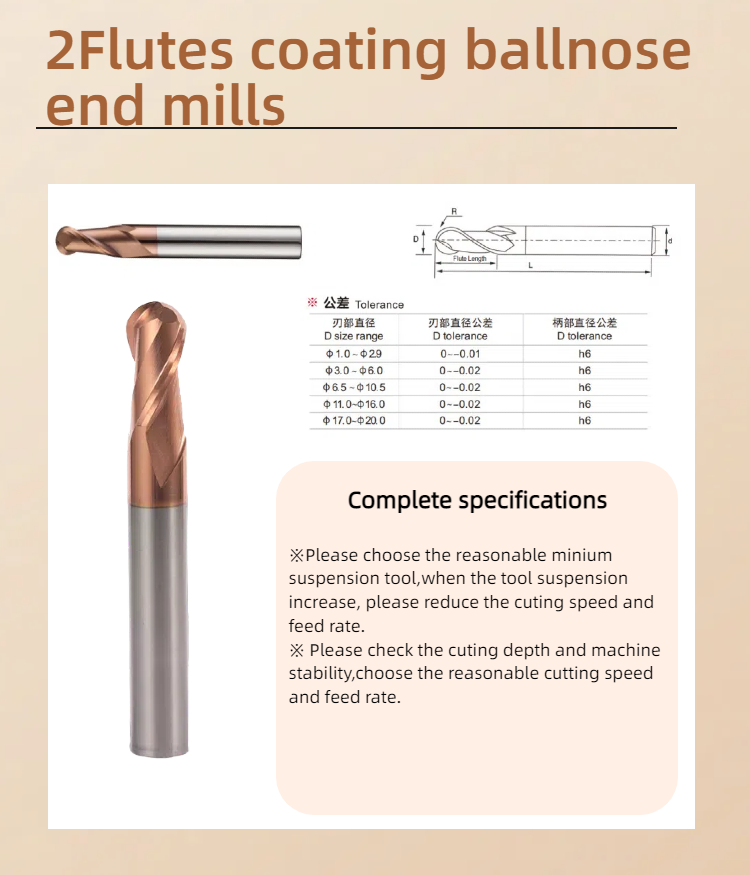

2Flutes coating ballnoseend mills

※Please choose the reasonable miniumsuspension tool,when the tool suspensionincrease, please reduce the cuting speed andfeed rate.

※ Please check the cuting depth and machinestability,choose the reasonable cutting speedand feed rate.

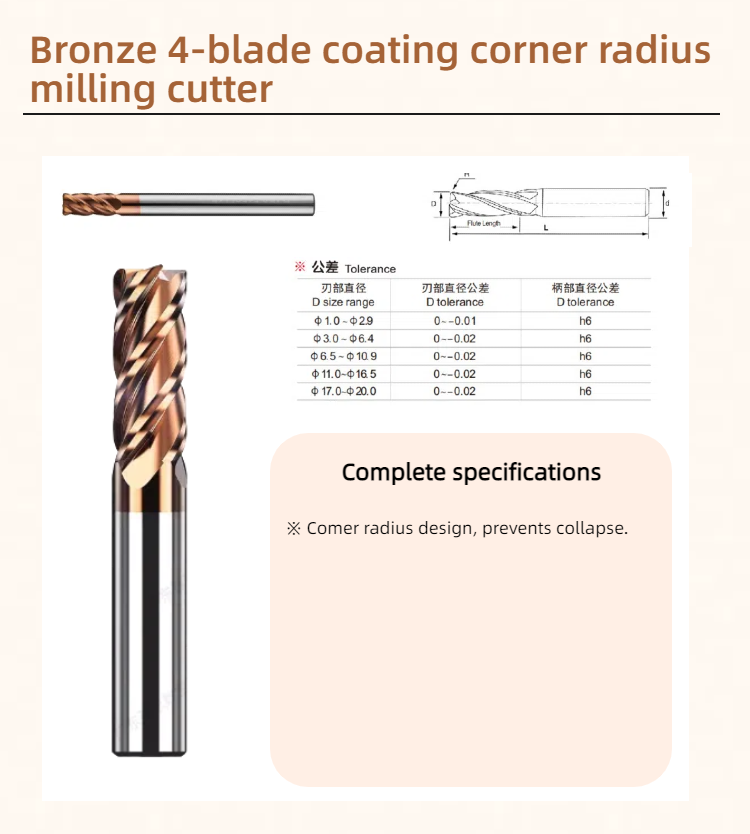

Bronze 4-blade coating corner radiusmilling cutter

※ Comer radius design, prevents collapse.

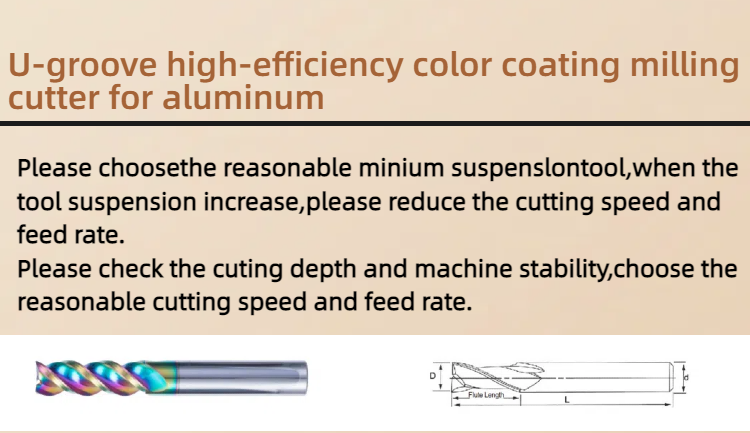

U-groove high-efficiency color coating millingcutter for aluminum

Please choosethe reasonable minium suspenslontool,when thetool suspension increase,please reduce the cutting speed andfeed rate.Please check the cuting depth and machine stability,choose thereasonable cutting speed and feed rate.

THREAD SERIES

To achieve high-precision threaded holes, using a thread milling cutter withadjustable tool radius is much easier than producing high-precision taps.When machining small-diameter threads, especially when machining hardand high-temperature materials, taps can sometimes break, blocking thethreaded hole and even rendering the part scrapped. With a thread millingcutter, since the tool diameter is smaller than the hole being machined, even ifit breaks, it won't block the hole and is easily removed, preventing part scrap.

Compared to tapping, thread milling significantly reduces cutting force, whichis particularly important when machining large-diameter threads. lt solves theproblem of excessive machine load and inefficiency.

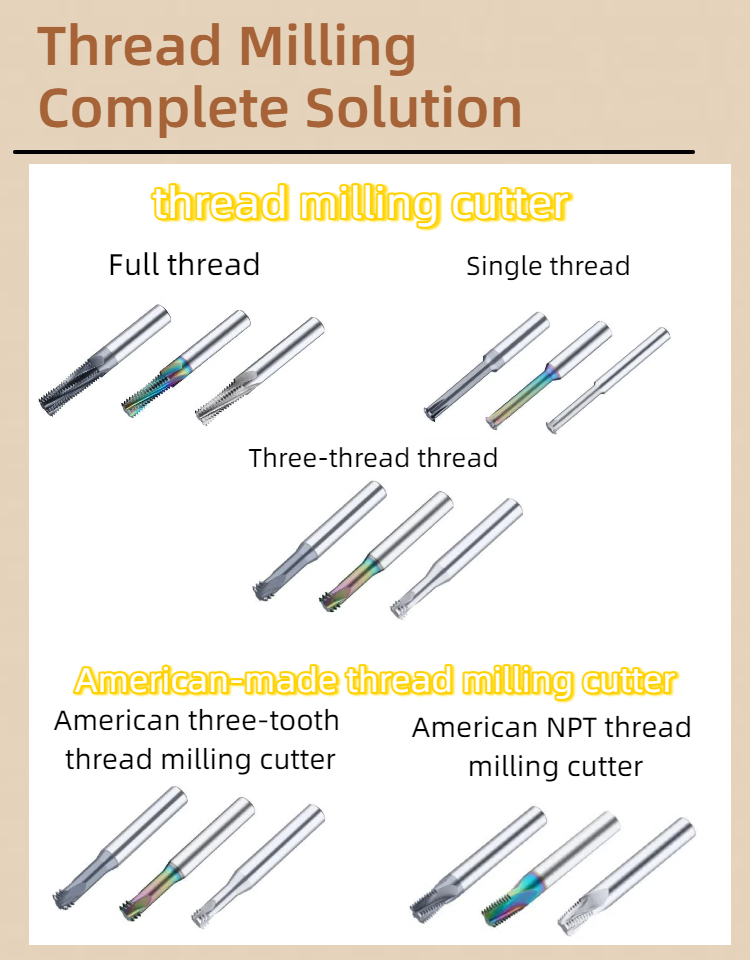

Thread MillingComplete Solution

thread milling cutter

1.Full thread 2.Single thread 3.Three-thread thread

American-made thread milling cutter

1.American three-tooththread milling cutter 2.American NPT threadmilling cutter 3.AmericanUNC/UNF/UNEFthread milling cutter

Inch thread milling cutters

1.Imperial Rc thread millingcutter(RC=PT=ZG) 2.Inch BSP(G) thread millingcutter

thread milling cutter

Single-thread milling cutters:

Can process internal and external threads of varying pitches and any straightshank, without rotation restrictions.Affordable, wide processing range, easy prototyping, and highly versatile.Triple-thread milling cutters:

Mills the first thread, then re-cuts the last two threads for fixed-pitch processingHighly cost-effective and faster than single-thread milling cutters.Full-thread milling cutters:

Suitable for efficient fixed-pitch processing of large quantities of threads of thesame specification.One-piece, one-cut production for high efficiency.