Milling range: high-quality toolholders, tool heads and inserts – a one-stop shop

Milling cutter head (Face Mill / Indexable Milling Cutter)

Milling cutter discs are mainly used for face milling (machining planes) and step milling, and are key tools for improving production efficiency.

✅ High Efficiency, High Cutting Volume

Typically equipped with multiple (4-10 or more) inserts, these tools utilize numerous cutting edges, achieving very high metal removal rates (MRR).

They are suitable for roughing and semi-finishing operations at high speeds and feed rates.

✅ Excellent Processing Stability

The rigid structure, particularly the short overhang on the machine spindle, effectively absorbs cutting vibrations.

This makes them excellent for machining large workpieces or difficult-to-machine materials.

✅ Cost-Effective

Using indexable inserts, when a cutting edge wears, a new edge can be applied simply by rotating the insert, eliminating the need for resharpening. This significantly reduces downtime and tooling costs.

✅ Wide Range of Applications

By replacing different insert types (such as square shoulders, round noses, and chamfers), a variety of machining operations, including flat surfaces, stepped edges, and chamfers, can be achieved.

End Mill Holder / Arbor Milling Cutter

End mill holders (often called end mills) are primarily used for peripheral milling, machining workpiece sides, grooves, and complex contours.

Key Advantages:

✅ High Flexibility and Precision

The large aspect ratio allows for deep machining into workpiece cavities or confined areas.

It is ideal for machining complex two- and three-dimensional contours and is a core tool for moldmaking and precision part machining.

✅ Versatility

It can perform both side cutting (like a turning tool) and end cutting (like a drill).

Different tool paths enable a variety of tasks, including grooving, profiling, and engraving.

✅ High Processing Quality

Because the cutting force is primarily distributed along the tool's axis, radial pressure on the workpiece is reduced, resulting in smoother surface finishes and higher dimensional accuracy.

Indexable Inserts

Milling inserts are the "heart" of indexable tools, and their performance directly impacts machining efficiency, surface quality, and tool life.

Core Advantages:

✅ Excellent Performance and Diverse Material Selection

Made from high-performance carbide, ceramics, CBN (cubic boron nitride), and other materials, they can meet the machining needs of a wide range of materials, from steel and cast iron to high-temperature alloys and titanium alloys.

Insert surfaces are typically coated with PVD or CVD, significantly enhancing wear and impact resistance.

✅ Economical

A single insert typically has two to six usable edges (depending on its shape). When worn, simply rotate the insert for continued use until all edges are worn, requiring a new insert. This maximizes material utilization.

✅ Easy Replacement and High Degree of Standardization

Inserts typically utilize standardized designs, enabling quick replacement without the need for tool setting. This significantly reduces auxiliary time and increases machine tool availability.

One-stop shopping

CNC Milling Tool Series

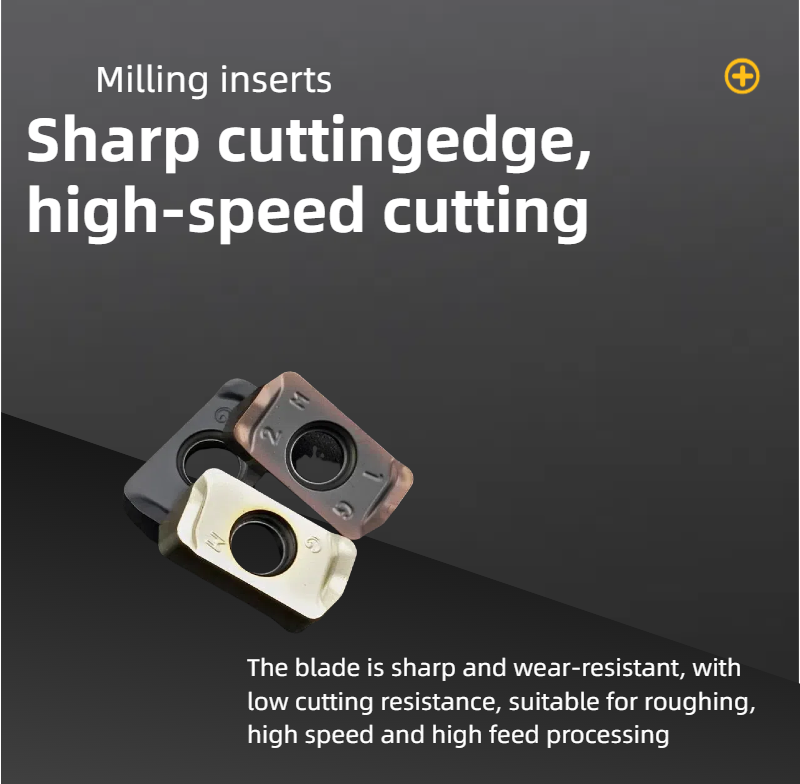

Sharp cuttingedge,high-speed cutting

Milling inserts

The blade is sharp and wear-resistant, withlow cutting resistance, suitable for roughinghigh speed and high feed processing

Widely used

The sharp edge design reduces cutting resistance duringcutting.The selected alloy materials are wear-resistant anddurable.They are suitable for ordinary steel, mold steel,stainless steel, etc.

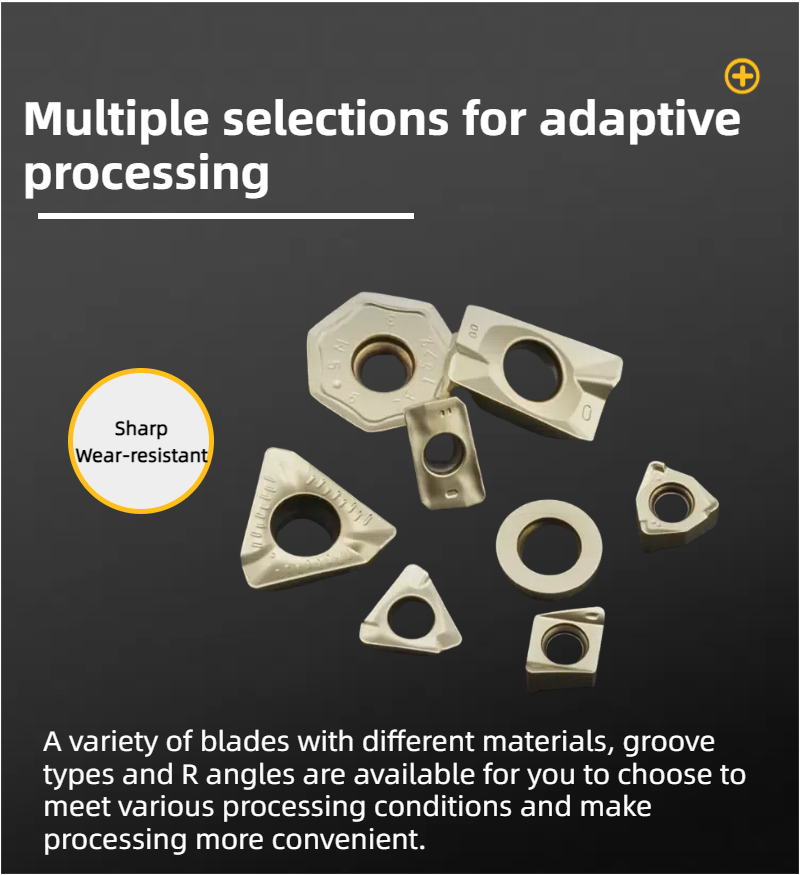

Multiple selections for adaptiveprocessing

A variety of blades with different materials, groovetypes and R angles are available for you to choose tomeet various processing conditions and makeprocessing more convenient.

Double-sided,economical and effcient

The double-sided groove design and four cutting edgesprovide high strength for high-speed, high-feed cutting.improving efficiency.

Selected materialsarewidely used

The sharp cutting edge design reduces cutting resistanceduring cutting.The selected alloy materials are wear-resistant and durable.lt is suitable for ordinary steel, moldsteel,stainless steel, cast iron, high-temperature alloys, etc.

Product Display

One-stop shopping

Double-sided milling cutter

Center drilling and millingcutter bar