ER/UM Collet Wrench Guide 2025 | High-Precision Models Review

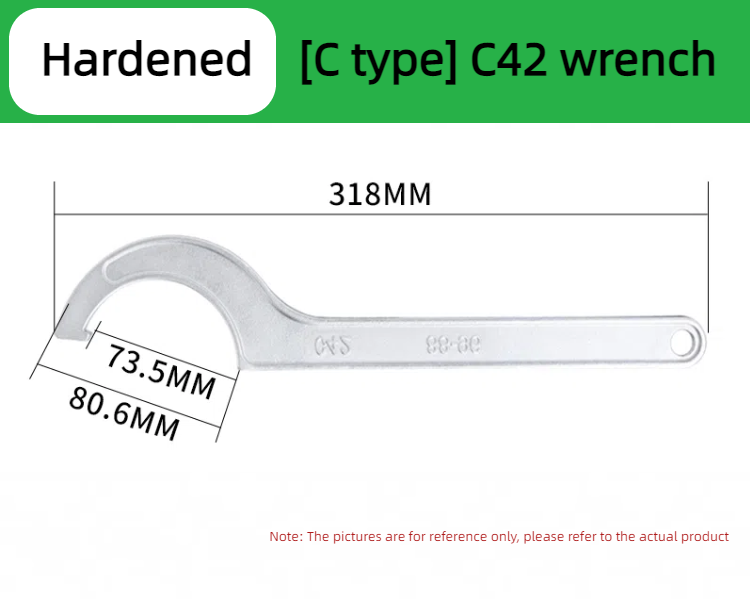

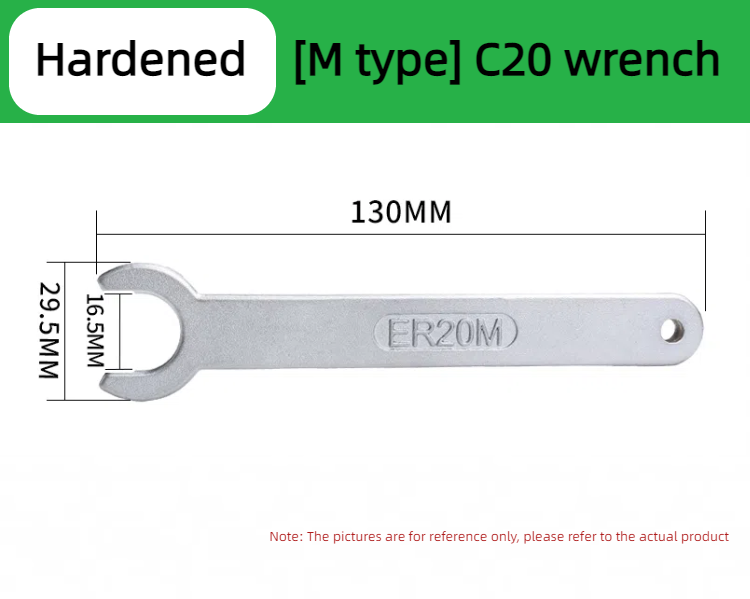

Standardized design: The shape and torque parameters of the bayonet of the ER wrench and the ER chuck (such as ER11, ER20, etc.) are strictly matched to ensure that the chuck achieves a constant clamping force during installation, avoiding tool vibration or loosening due to adaptation errors, especially suitable for precision machining (such as mold milling, electronic component engraving) with extremely high precision requirements.

Uniform transmission of clamping force: Through the lever principle or torque structure design, the wrench can evenly distribute the force on the chuck circumference, reduce the risk of chuck deformation, thereby ensuring the coaxiality of the tool during rotation (the error can be controlled at 0.01mm level), and improving the surface finish and processing consistency of the workpiece.

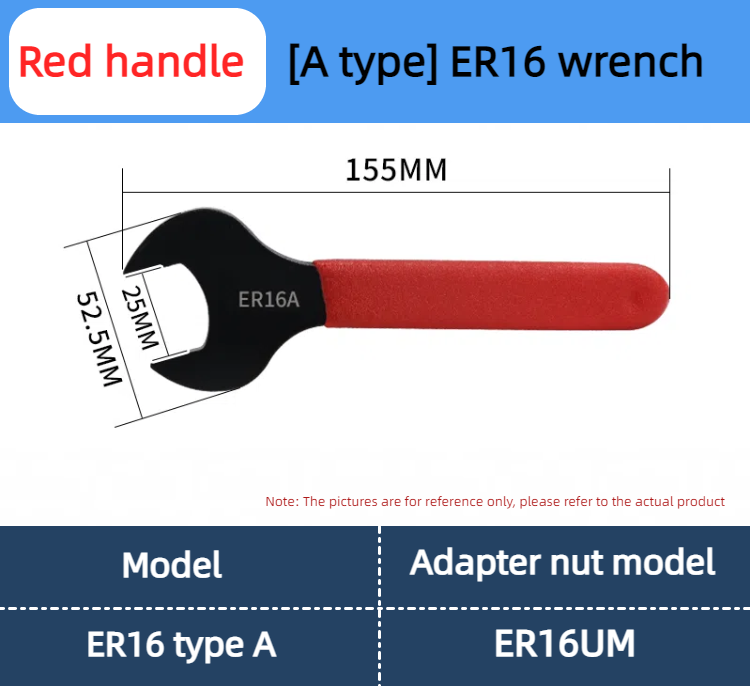

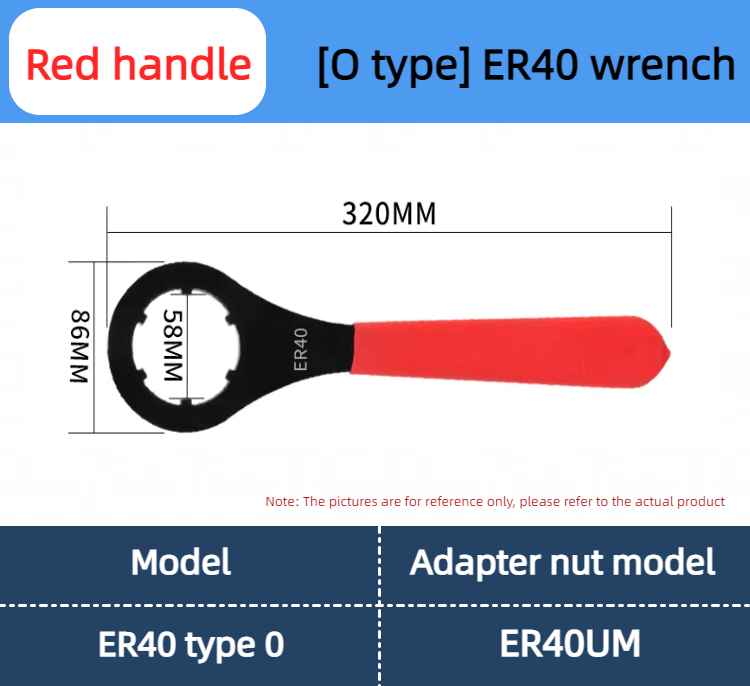

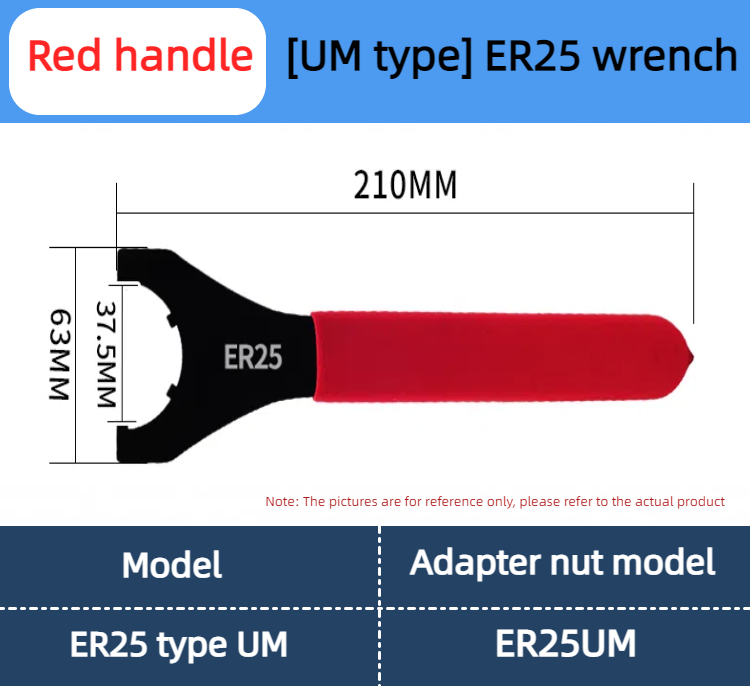

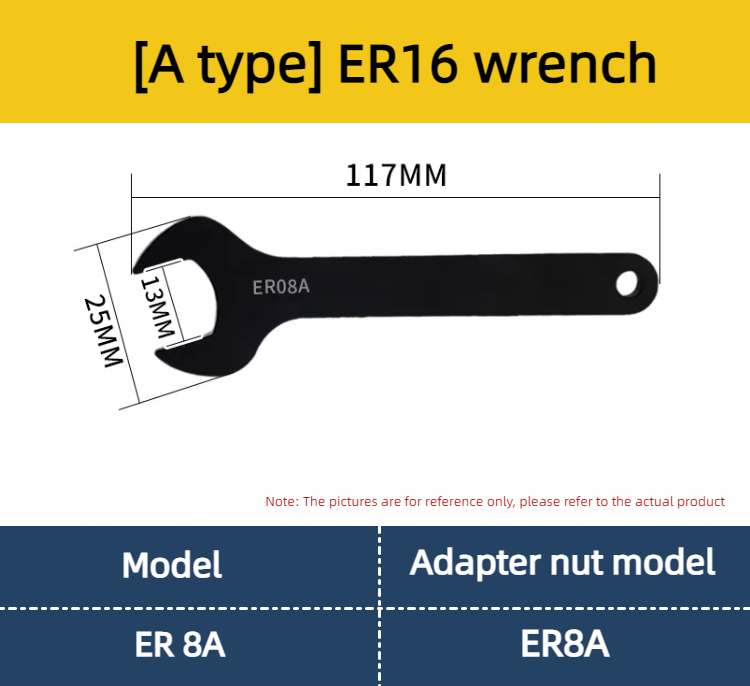

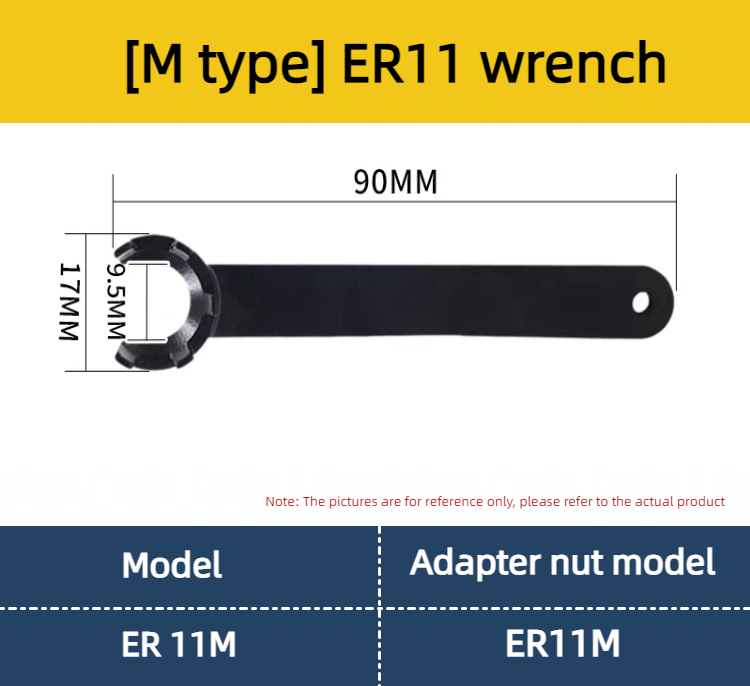

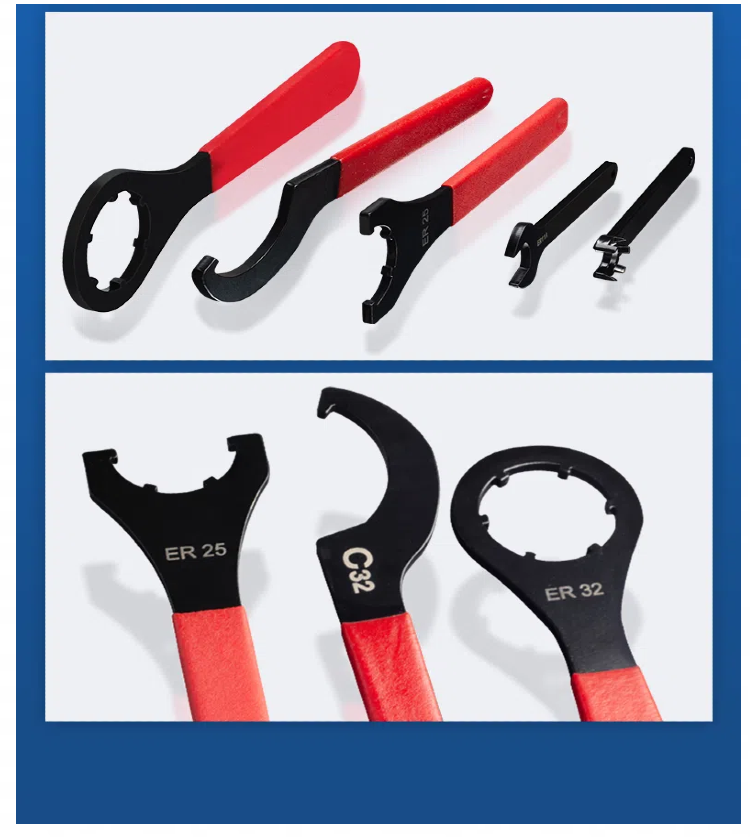

ER wrench: only used to install/remove ER chucks (16° taper, with elastic groove structure), commonly used in CNC machine tools, engraving machines and other equipment, the clamping tool diameter is usually 0.5-32mm.

Ordinary wrenches (such as open-end wrenches, plum wrenches): general-purpose tools used to tighten standard bolts/nuts, not suitable for the groove structure and torque requirements of ER chucks.

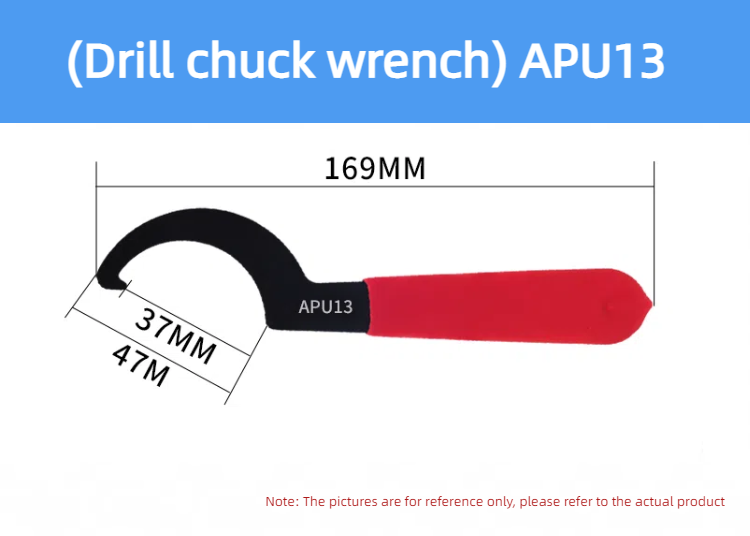

Other special wrenches (such as milling wrenches, drill chuck wrenches):

Milling wrenches: designed for tool handle interfaces (such as BT, HSK), the bayonet shape is polygonal or long strip;

Drill chuck wrenches: used for three-jaw drill chucks, rotated by gear meshing, completely different from the elastic clamping principle of ER chucks