All the CNC turning and drilling tools you need are available here

Best CNC Cutting Tools 2025: Top Picks for Precision Machining

Are you searching for high-performance CNC cutting tools that deliver accuracy, durability, and cost-efficiency? Whether you're machining metal, wood, or composites, the right CNC tools can reduce production time, minimize waste, and boost your bottom line. In this guide, we’ve curated the top CNC cutting tools based on real-world performance, customer reviews, and industry standards—so you can buy with confidence.

Why Choose Our CNC Cutting Tools?

When it comes to CNC machining, precision is non-negotiable. Our selection of CNC end mills, carbide drill bits, and indexable turning tools are engineered to meet the demands of modern manufacturing. Here’s what sets them apart:

Superior Material: Made from micrograin carbide and coated with TiAlN or TiCN for extended tool life (up to 3x longer than standard tools).

Versatile Applications: Ideal for CNC milling, turning, and drilling in stainless steel, aluminum, titanium, and plastics.

Precision Engineering: Strict tolerance control (±0.001mm) ensures consistent results even in high-speed operations.

Cost-Effective: Bulk pricing options and long tool life reduce per-part machining costs.

Top CNC Cutting Tools for Sale in 2025

1. Premium Carbide CNC End Mills – Best for Metal Machining

Our 4-flute carbide end mills are the go-to choice for roughing and finishing operations in steel and aluminum. With a high helix angle (35°), they excel at chip evacuation, preventing material buildup and heat damage. Available in diameters from 3mm to 20mm, these end mills are perfect for CNC routers and vertical machining centers.

Key Specs:

- Material: Micrograin carbide with TiAlN coating

- Flute Length: 2-3x diameter

- Maximum RPM: 15,000

- Application: Steel, aluminum, brass

Price: $12.99 – $49.99 (bulk discounts available for 10+ units)

2. Indexable U Drills – Fast Hole Machining

For efficient hole drilling in thick materials, our CNC U drills (also called indexable insert drills) cut setup time by 50%. The replaceable carbide inserts eliminate the need for regrinding, saving maintenance costs. Suitable for diameters 12mm to 50mm, they’re widely used in automotive and aerospace manufacturing.

Key Specs:

- Insert Material: WC-Co carbide

- Coolant Through: Yes (reduces tool wear)

- Depth Capacity: 3x diameter

- Application: Cast iron, stainless steel, high-temp alloys

Price: $39.99 – $129.99 (includes 2 inserts per drill)

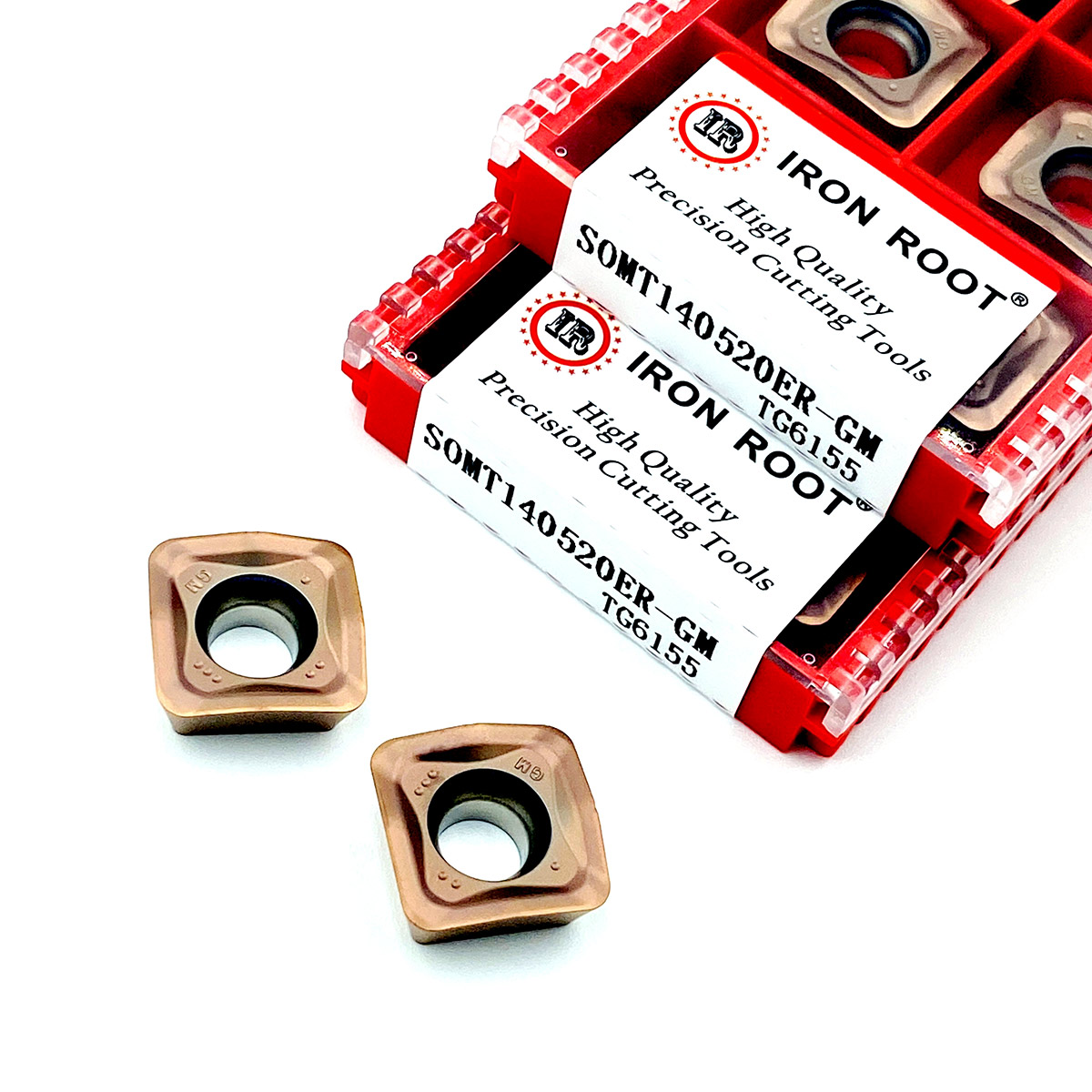

3. Titanium Nitride Coated CNC Turning Tools

Our CNC turning inserts with TiN coating deliver exceptional performance in continuous and interrupted cuts. The positive rake angle reduces cutting forces, making them ideal for thin-walled parts. Compatible with most CNC lathes, they come in various geometries (CCMT, WNMG, TNMG) to match your specific machining needs.

Key Specs:

- Coating: TiN (high hardness, low friction)

- ISO Grade: P30-M30 (versatile for steel and cast iron)

- Edge Preparation: Honed (prevents chipping)

- Application: External turning, facing, boring

Price: $8.99 per insert (10-pack: $79.99)

How to Choose the Right CNC Cutting Tools for Your Needs

Not sure which tool fits your application? Consider these factors:

Material to Machine: Use carbide tools for metals, high-speed steel (HSS) for wood/plastics.

Machine Type: Ensure compatibility with your CNC mill, lathe, or router.

Cutting Parameters: Match tool diameter and coating to your spindle speed and feed rate.

Still unsure? Contact our technical support team with your machining requirements, and we’ll recommend the perfect tool.