Crown CNC High-Speed Deep Hole Drill - Cutter Head/Shank Internal Cooling

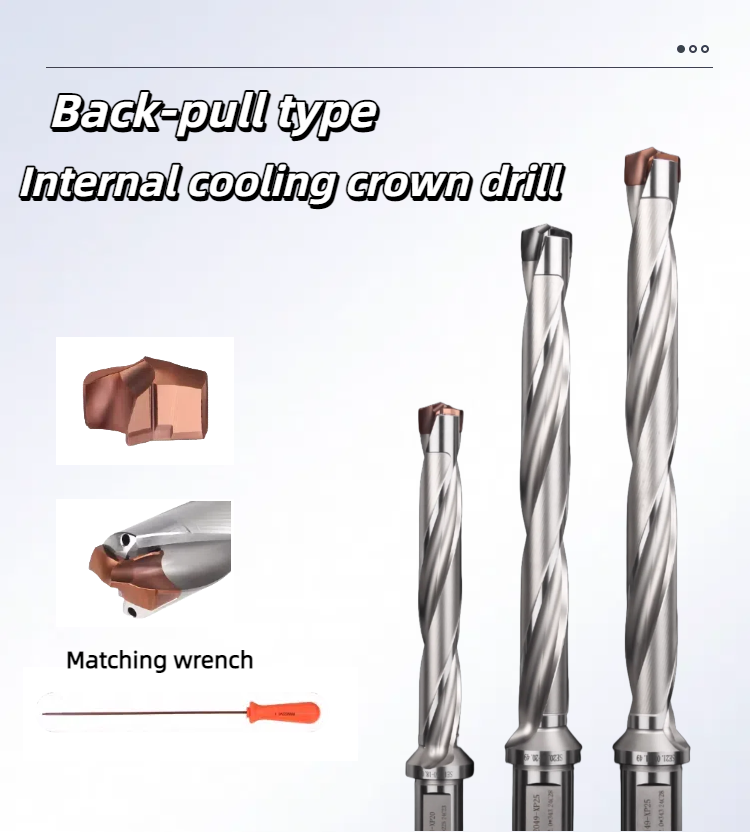

Advantages of the Back-Pull Crown Drill

1. Easier installation and disassembly, even beginners can quickly master it.

2. High stability, high hardness, and excellent wear resistance. This ensures smooth operation and strong cutting force during machining, preventing deformation and slipping.

3. Excellent cooling performance. The extended internal coolant design utilizes internal cooling channels to effectively lower drilling temperatures, reduce wear, extend service life, and improve machining accuracy.

4. Wide range of applications, with multiple models available.

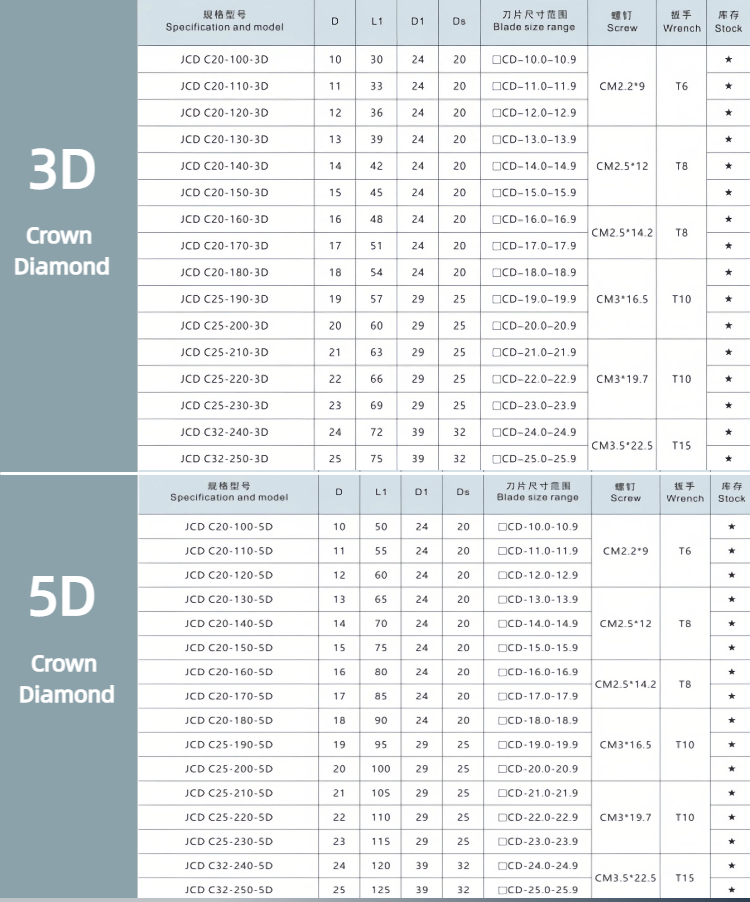

Advantages of Insert Crown Drills

1. The insert design facilitates insert replacement. When a worn insert is encountered, it can be quickly replaced with a new one, reducing downtime and improving productivity.

2. Precise positioning: Multiple locating surfaces are typically provided for repeatable and precise insert positioning, ensuring machining accuracy and extending insert life.

3. Versatile: One toolholder can accommodate a range of insert diameters. Compared to standard toolholders, these handles offer greater rigidity and larger diameters, reducing tool costs and simplifying tool inventory management.

Advantages of Saber-Tooth Crown Drills

1. High cutting efficiency. The unique saber-tooth shape effectively reduces cutting resistance, increases cutting speed, and rapidly penetrates the material, significantly improving work efficiency.

2. The saber-tooth design optimizes chip breaking, ensuring smooth chip evacuation and preventing chip blockage that can affect machining quality and tool life.

3. The saber-tooth blades are precision-machined to ensure consistent size and position across each blade. This evenly distributes cutting force, improving machining accuracy and surface quality, and achieving a high-quality finish on machined holes.

4. Widely adaptable, it can process most metal materials, including medium-carbon steel, high-carbon steel, quenched and tempered steel, stainless steel, cast iron, and non-ferrous metals, demonstrating excellent machining performance across a wide range of hardness and types.

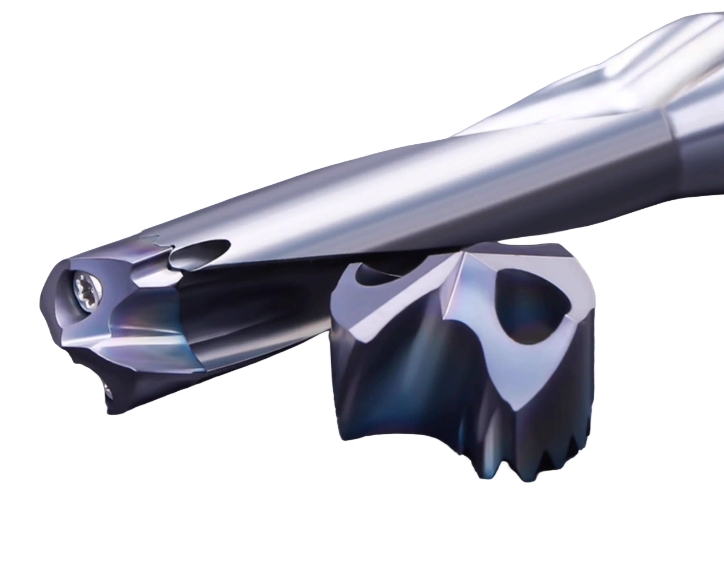

Back-pull typeInternal cooling crown dr!!

The blade of a back-pull tool is connected to the toolholder via a specific back-pull mechanism. This typically involves an internal or threaded hole in the toolholder, with the blade having a corresponding attachment structure. A screw or other tensioning device is then tightened from the rear of the toolholder, creating an interference fit between the blade and the handle, thus firmly securing the blade to the handle

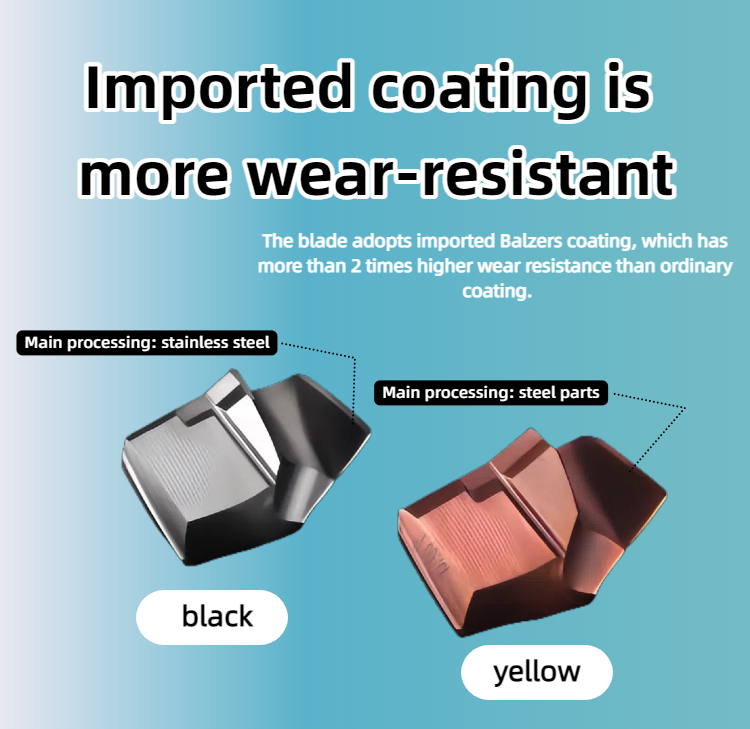

Imported coating ismore wear-resistant

The blade adopts imported Balzers coating, which hasmore than 2 times higher wear resistance than ordinarycoating.

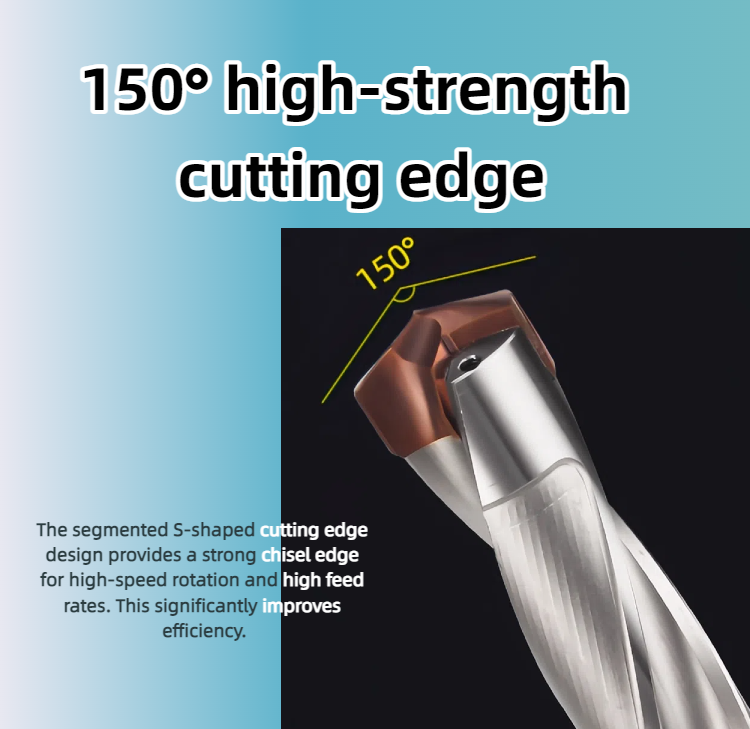

150°high-strengthcutting edge

The segmented s-shaped cutting edgedesign provides a strong chisel edgefor high-speed rotation and high feedrates. This significantly improvesefficiency.

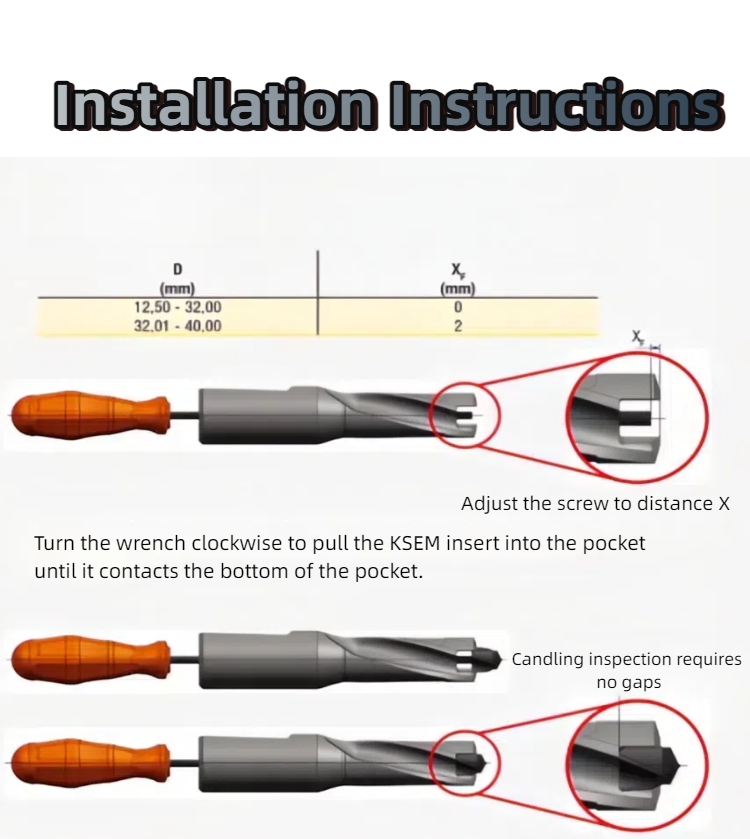

Installation Instructions

Turn the wrench clockwise to pull the KSEM insert into the pocketuntil it contacts the bottom of the pocket.

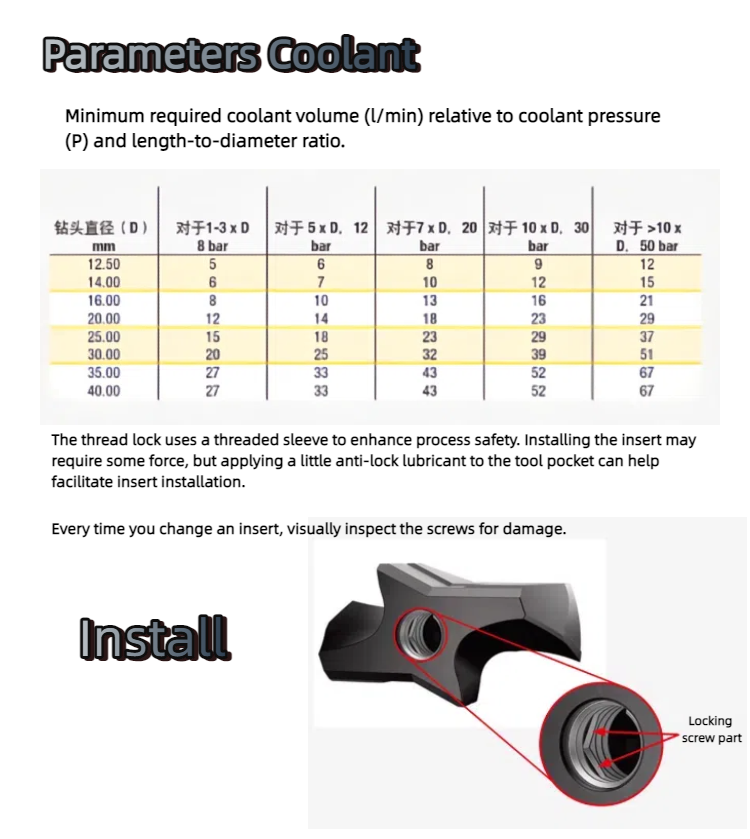

Parameters coolant

Minimum required coolant volume (l/min) relative to coolant pressure(P)and length-to-diameter ratio.

The thread lock uses a threaded sleeve to enhance process safety. installing the insert mayrequire some force, but applying a little anti-lock lubricant to the tool pocket can helpfacilitate insert installation.

Notice:Every time you change an insert, visually inspect the screws for damage

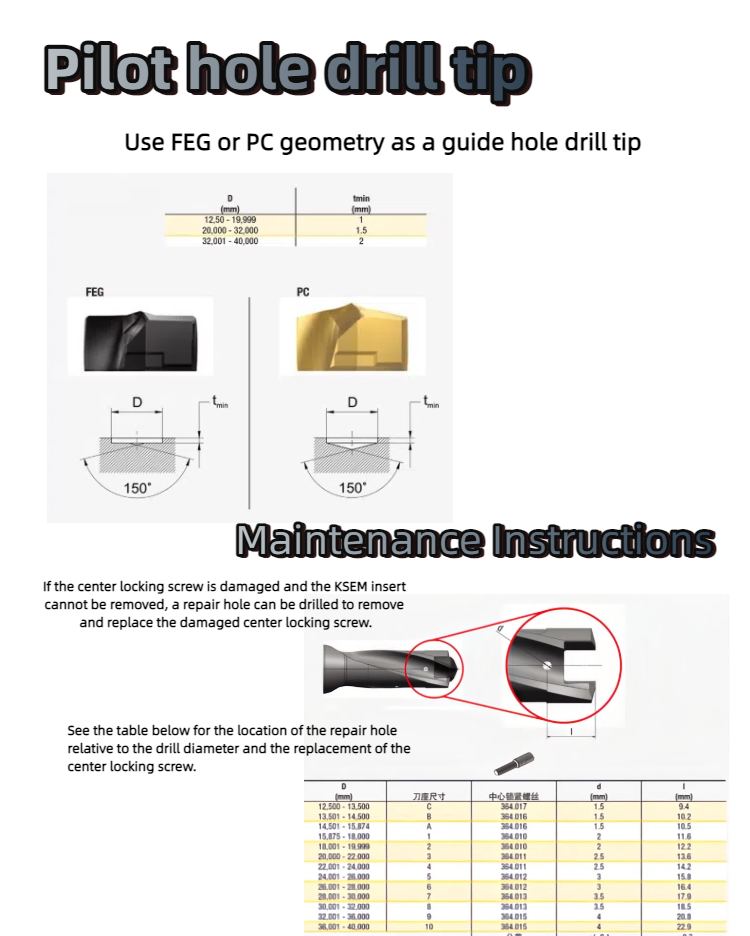

Pilot hole drill tip

Use FEG or Pc geometry as a guide hole drill tip

Maintenance Instructions

If the center locking screw is damaged and the KSEM insertcannot be removed, a repair hole can be drilled to removeand replace the damaged center locking screw.

See the table below for the location of the repair holerelative to the drill diameter and the replacement of thecenter locking screw.

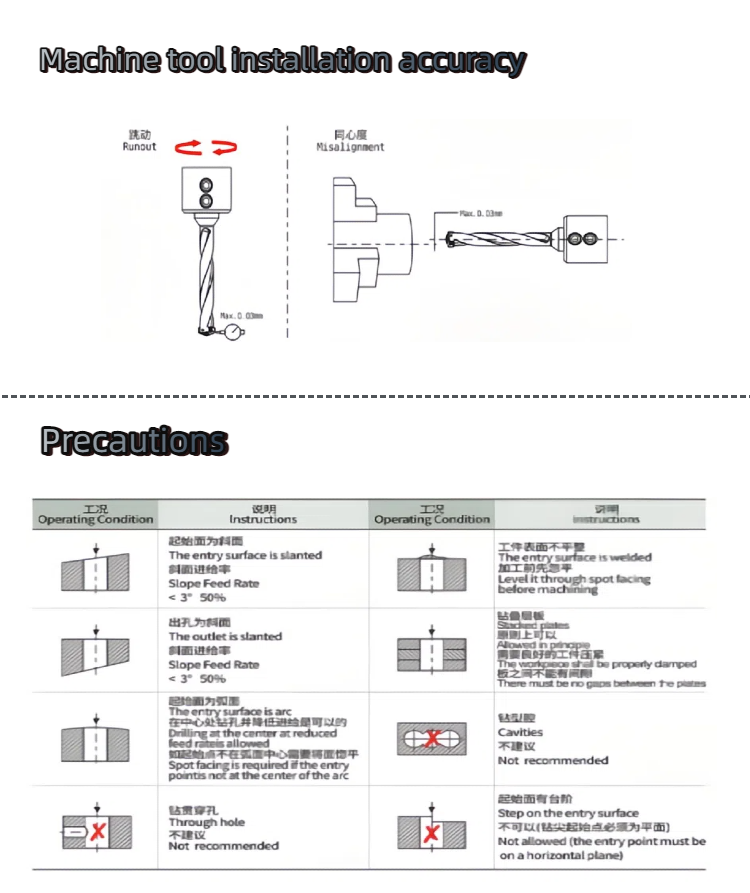

Machine tool installation accuracy

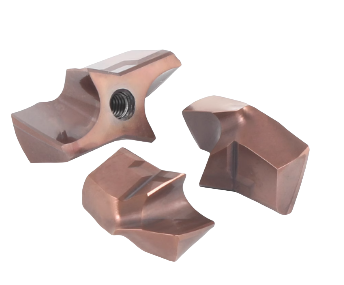

Saber-tooth Crown Drill

Saber-tooth drills typically feature sharp cutting edges shaped like the teeth of a saber, enabling them to easily cut into the material during machining. The blades are typically replaceable, secured to the toolholder via a specific connection method, such as a slotted or pull-back mechanism, making it easy to replace worn blades and improving machining efficiency.

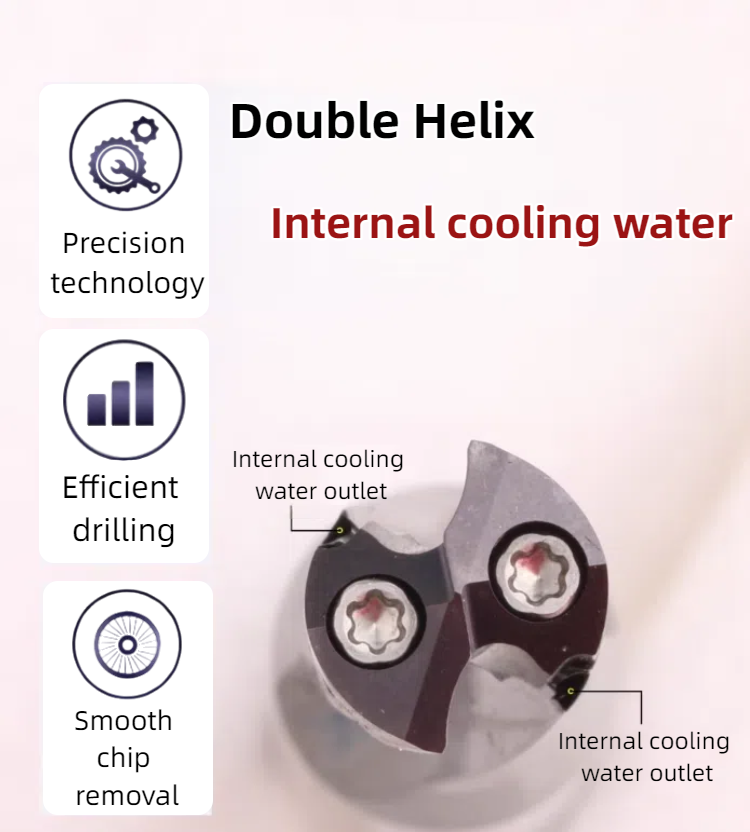

Double HelixInternal cooling water

Quenching and hardeningstrong and durable

Selected H13 high hard steel material hasexcellent wear resistance and shock resistance

Slot-inInternalCooling Crown Drill

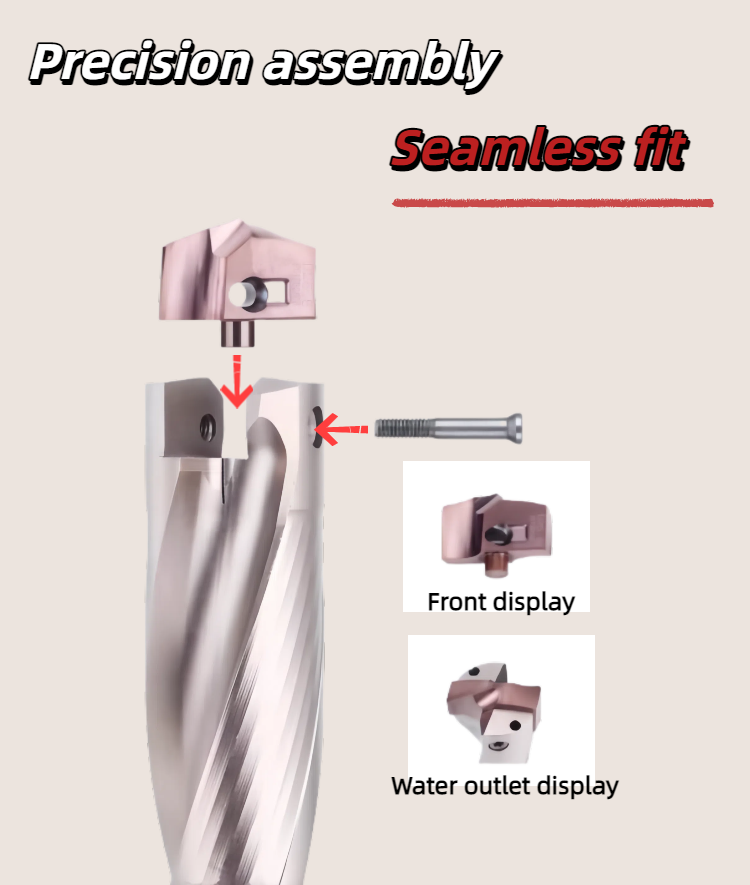

Precision assemblySeamless fit

Spade drill inserts for efficient drillinc

Deep hole processing toolwith smooth chipremoval

Double helixinner hole wateroutlet

The deephole wateroutlet designcan bettercooltheshank,increase the service life ofthe dril!bitandmakeitmore durable

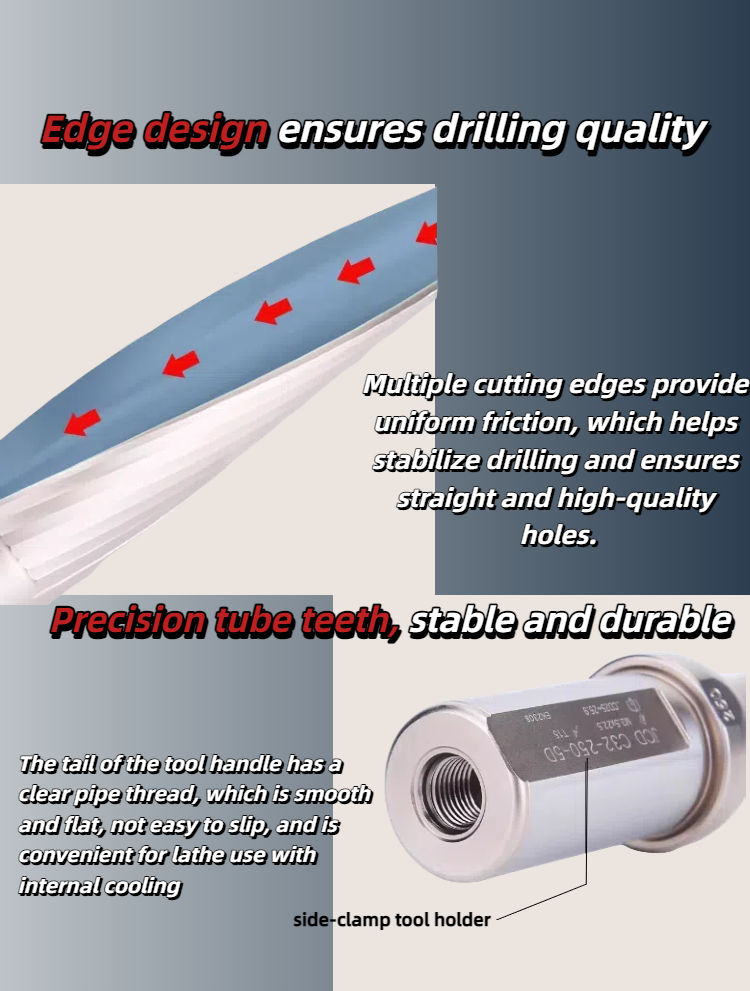

Edge design ensures drilling quality

Multiole cutting edges provideuniform friction, which helpsstabilize drillingandensuresstraight and high-quality

holes.

Precision tube teeth, stable anddurable

The tailofthe too!handle has aclearpise thread, whichis smoothandflat,noteasytoslip,andisconvenient forlathe use withinternalcooling

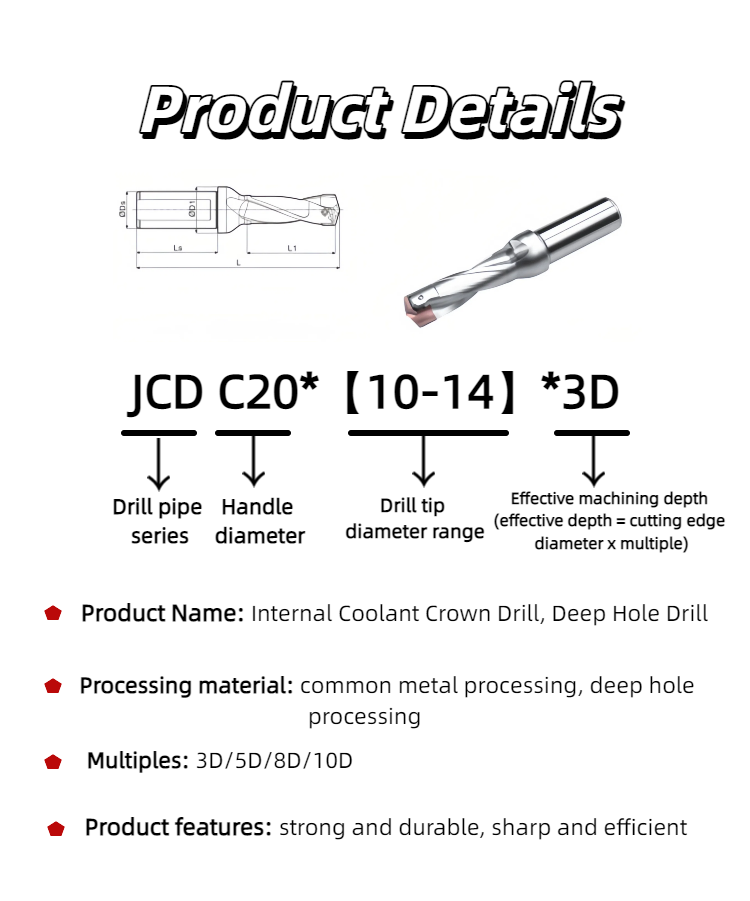

Product Details

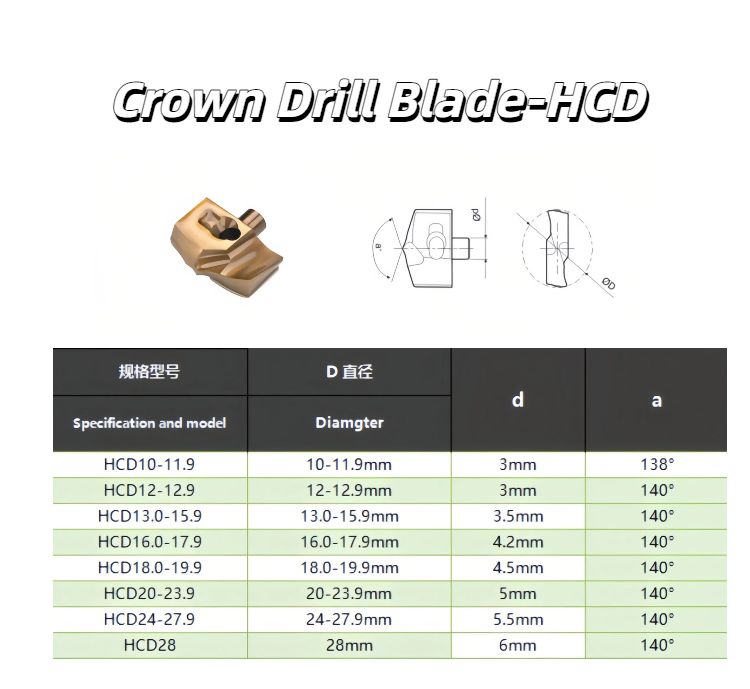

Grown Dri!! Blade-HGD